Quality Color Masterbatch For XLPE Materials

Release time:

2025-08-25 10:53

Source:

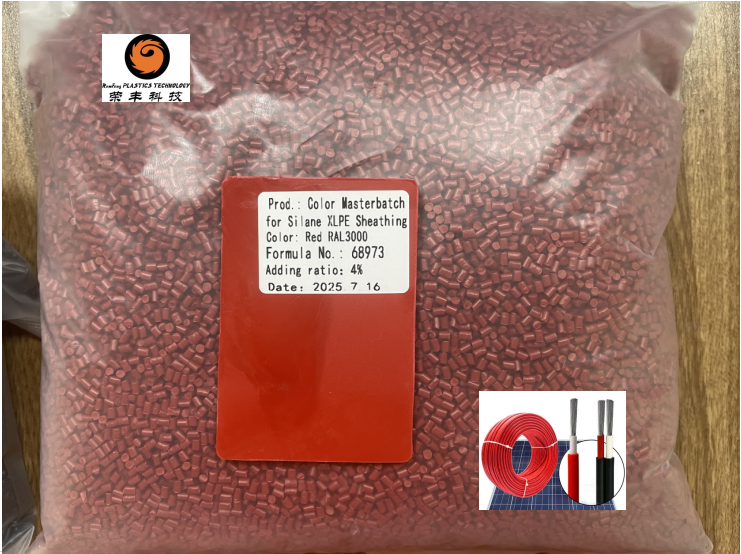

**Custom Color Masterbatch for Silane XLPE Sheathing**

In the world of cable manufacturing, the importance of color in wire and cable sheathing cannot be overstated. Custom color masterbatches play a pivotal role in enhancing both the aesthetic appeal and functional performance of materials such as silane cross-linked polyethylene (XLPE). This article explores the significance of custom color masterbatches for silane XLPE sheathing, focusing on their benefits, formulation, and applications.

**Understanding Silane XLPE Sheathing**

Silane XLPE is a versatile polymer known for its excellent electrical insulation properties, thermal stability, and resistance to moisture. These characteristics make it an ideal choice for various applications, particularly in the electrical and telecommunications sectors. However, the natural appearance of XLPE is typically a milky white or translucent shade, which may not meet the specific requirements of certain projects or brands.

The introduction of color into XLPE sheathing not only enhances the visual appeal but also aids in identification and differentiation of cables in complex installations. This is where custom color masterbatches come into play, providing manufacturers with the ability to produce colored sheathing that meets both functional and aesthetic needs.

**The Role of Custom Color Masterbatches**

Custom color masterbatches are concentrated mixtures of pigments and additives that are formulated to impart color to base polymers like XLPE. These masterbatches allow for precise control over color properties, ensuring that manufacturers can achieve the desired hue, shade, and consistency in their final products.

One of the key advantages of using custom color masterbatches is the flexibility they offer in terms of color matching. Manufacturers can work closely with suppliers to create specific colors that align with brand identity or project specifications. This capability is especially crucial in industries where color coding is essential for safety and compliance, such as electrical wiring.

**Benefits of Using Custom Color Masterbatches**

1. **Enhanced Aesthetic Appeal**: Custom color masterbatches allow manufacturers to produce visually striking cables that can attract customers and enhance brand recognition. A well-colored cable can stand out in a competitive market.

2. **Improved Functionality**: Beyond aesthetics, colored sheathing can serve functional purposes, such as aiding in the identification of cable types, voltage ratings, or specific applications. This is particularly important in complex installations where multiple cables are present.

3. **Customization and Versatility**: Manufacturers can create unique color formulations tailored to specific projects or customer preferences. This level of customization ensures that companies can meet diverse market demands.

4. **Quality Control**: Using masterbatches provides better control over the quality and consistency of color throughout production runs. This reduces the likelihood of color variations that can occur when using powdered pigments directly.

5. **Cost Efficiency**: While the initial investment in custom color masterbatches may be higher than using standard colors, the long-term benefits in terms of reduced waste, improved production efficiency, and enhanced product value can offset these costs.

**Formulation Considerations for Custom Color Masterbatches**

Creating an effective custom color masterbatch involves several formulation considerations. The choice of pigments is crucial, as they must be compatible with silane XLPE and meet the desired performance criteria. Additionally, the concentration of pigments must be optimized to achieve the desired color intensity without compromising the mechanical properties of the base polymer.

Additives such as UV stabilizers, antioxidants, and processing aids may also be included in the masterbatch formulation to enhance the overall performance of the colored sheathing. These additives can improve the durability and longevity of the cable, making it suitable for various environmental conditions.

**Applications of Colored Silane XLPE Sheathing**

Colored silane XLPE sheathing has a wide range of applications across different industries. In the electrical sector, it is commonly used for power cables, control cables, and communication cables. The ability to customize colors allows manufacturers to meet specific requirements for different applications, ensuring that cables are easily identifiable and compliant with industry standards.

In addition to electrical applications, colored XLPE sheathing is increasingly being used in consumer electronics, automotive wiring, and construction materials. The trend towards colorful and visually appealing products is driving demand for custom color masterbatches, making them an essential component of modern manufacturing processes.

**Conclusion**

Custom color masterbatches are a valuable asset in the production of silane XLPE sheathing, offering numerous benefits that enhance both aesthetic appeal and functionality. By allowing for precise color matching and customization, these masterbatches enable manufacturers to meet diverse market demands while maintaining high standards of quality and performance. As industries continue to evolve, the role of custom color masterbatches will only become more critical in ensuring that products not only perform well but also resonate with consumers. The future of cable manufacturing is undoubtedly colorful, and custom color masterbatches are at the forefront of this transformation.

Discover the perfect solution for adding vibrant, reliable color to your manufacturing process with our specialized Color Masterbatch for XLPE Materials. This product is meticulously formulated to meet the unique challenges of coloring cross-linked polyethylene, providing manufacturers with a dependable and efficient method to achieve precise color matching and outstanding visual results in their final products.

The key advantage of our Color Masterbatch for XLPE Materials lies in its excellent dispersion characteristics and thermal stability. It is engineered to withstand the rigorous conditions of XLPE processing, including high-temperature extrusion and the subsequent cross-linking stages. This ensures a flawless, streak-free color finish without any agglomerates, which is critical for applications like wire and cable insulation where surface quality is paramount.

We understand that performance cannot be compromised. Therefore, our Color Masterbatch for XLPE Materials is designed to integrate without interfering with the cross-linking reaction or degrading the material's essential properties. You can achieve bold, lasting color while maintaining the excellent electrical insulation, chemical resistance, and mechanical strength that make XLPE the material of choice for demanding industrial applications.

Partner with us for unparalleled color consistency and technical support. Our team is dedicated to helping you select the ideal Color Masterbatch for XLPE Materials from our wide range of standard and custom colors. Enhance your product line with confidence, knowing you have a colorant solution that delivers on both aesthetics and performance, streamlining your production and strengthening your brand identity.

Color Masterbatch For XLPE Materials