Blog

2025-08-24

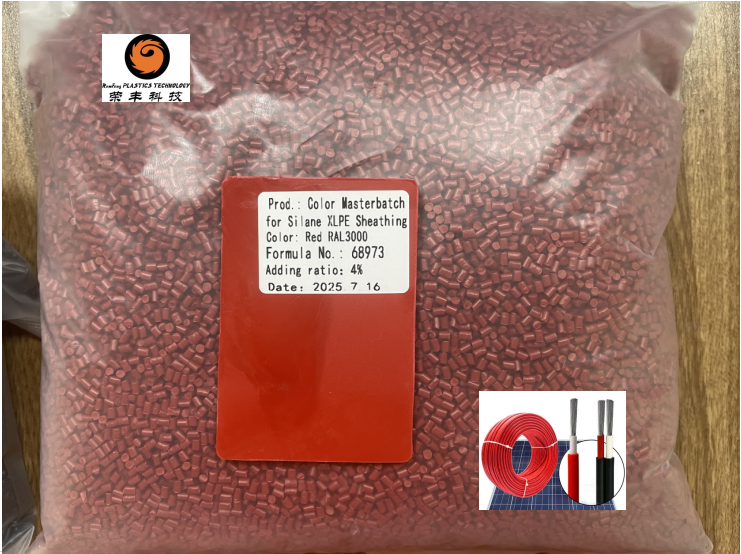

Unlocking the Potential of Color Masterbatch for XLPE Materials

Color masterbatch is a crucial component in the plastic industry, particularly when applied to cross-linked polyethylene (XLPE) materials. XLPE, known for its superior thermal and chemical resistance, is widely used in applications ranging from electrical insulation to piping systems. The integration of color masterbatch into XLPE processing offers a myriad of benefits that enhance both the functi

2025-08-21

Unlocking the Potential of XLPE Materials with Color Masterbatch: A Comprehensive Guide

Unlocking the Potential of XLPE Materials with Color Masterbatch Table of Contents Understanding XLPE Materials: Properties and Benefits What is Color Masterbatch? The Importance of Color Masterbatch in XLPE Applications Manufacturing Process of XLPE with Color Masterbatch Applications of XLPE Enhanced with Color Masterbatch Sustainability Aspects of XLPE and Color Masterbatch Chall

2025-08-18

Enhancing Wheat Straw Pellets with Color Masterbatch: A Guide for Professionals

In the realm of eco-friendly innovations, the integration of color masterbatch for wheat straw pellets has emerged as a transformative approach within the plastics and chemical sector. Wheat straw, a renewable agricultural byproduct, serves as an excellent base material for producing biodegradable pellets. The incorporation of color masterbatch not only enhances aesthetic appeal but also plays a p

2025-08-12

Enhancing Wheat Straw Pellets with Color Masterbatch: A Sustainable Approach

In the ever-evolving landscape of the plastic industry, the integration of sustainable practices has become more crucial than ever. One innovative approach to enhance the appeal and usability of biodegradable materials is the use of color masterbatch in the production of wheat straw pellets. Color masterbatch refers to a concentrated mixture of pigments and additives encapsulated in a carrier resi

2025-08-09

Enhancing Functional Properties of XLPO Materials with Color Masterbatch: A Comprehensive Guide

Enhancing Functional Properties of XLPO Materials with Color Masterbatch Table of Contents 1. Introduction to XLPO Materials 2. Understanding Color Masterbatch 3. Importance of Enhancing Functional Properties 3.1 Mechanical Strength and Durability 3.2 Thermal Stability 3.3 Aesthetic Appeal 4. Integration of Color Masterbatch with XLPO 4.1 Selection of Color Masterbatch 4.2 Processing Techniques 5.

2025-08-06

Understanding Color Masterbatch for XLPO Materials: A Comprehensive Guide

Color masterbatch for XLPO materials plays a crucial role in enhancing the visual appeal and functionality of plastic products. Masterbatches are concentrated mixtures of pigments and additives encapsulated in a carrier resin, which can be easily integrated into the base polymer during the manufacturing process. When it comes to XLPO materials, these color masterbatches are particularly beneficial

2025-08-03

Comprehensive Color Masterbatch Selection Guide: Choosing the Best for XLPO Applications

Comprehensive Color Masterbatch Selection Guide: Choosing the Best for XLPO Applications Table of Contents 1. Introduction to Color Masterbatches in XLPO 2. Understanding Color Masterbatches: An Overview 3. Types of Color Masterbatches Available 4. Key Factors to Consider When Selecting Color Masterbatches 4.1 Compatibility with XLPO 4.2 Performanc

2025-07-31

The Allure of Silk Effect Pellets for PLA 3D Print Filaments

In the realm of 3D printing, materials play a pivotal role in determining the quality and aesthetics of the final product. Among these materials, Silk Effect Pellets for PLA 3D print filaments have emerged as a popular choice for enthusiasts looking to elevate their projects. These specially formulated pellets add a distinctive sheen to printed items, providing a luxurious finish reminiscent of si