PRODUCTS

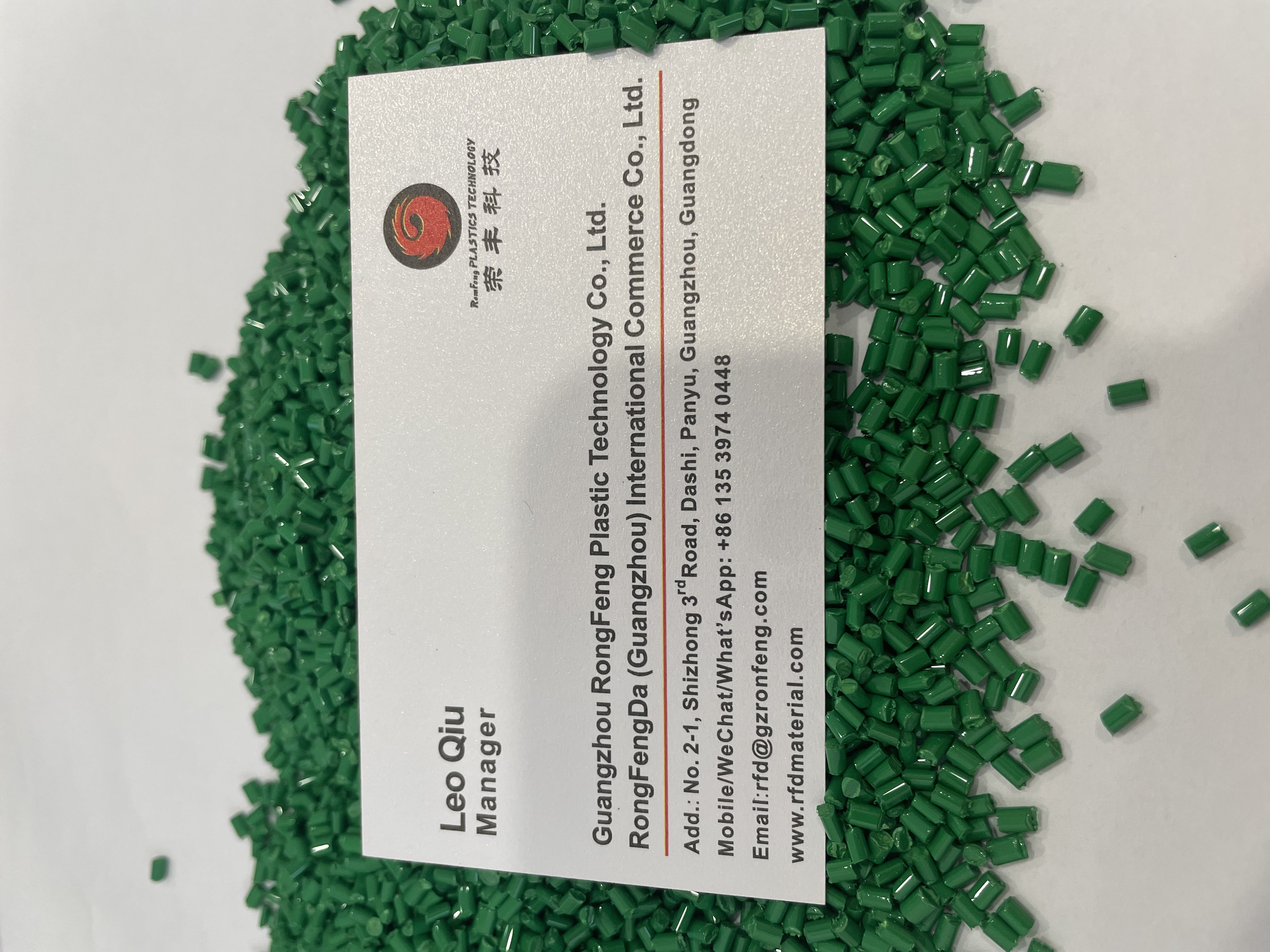

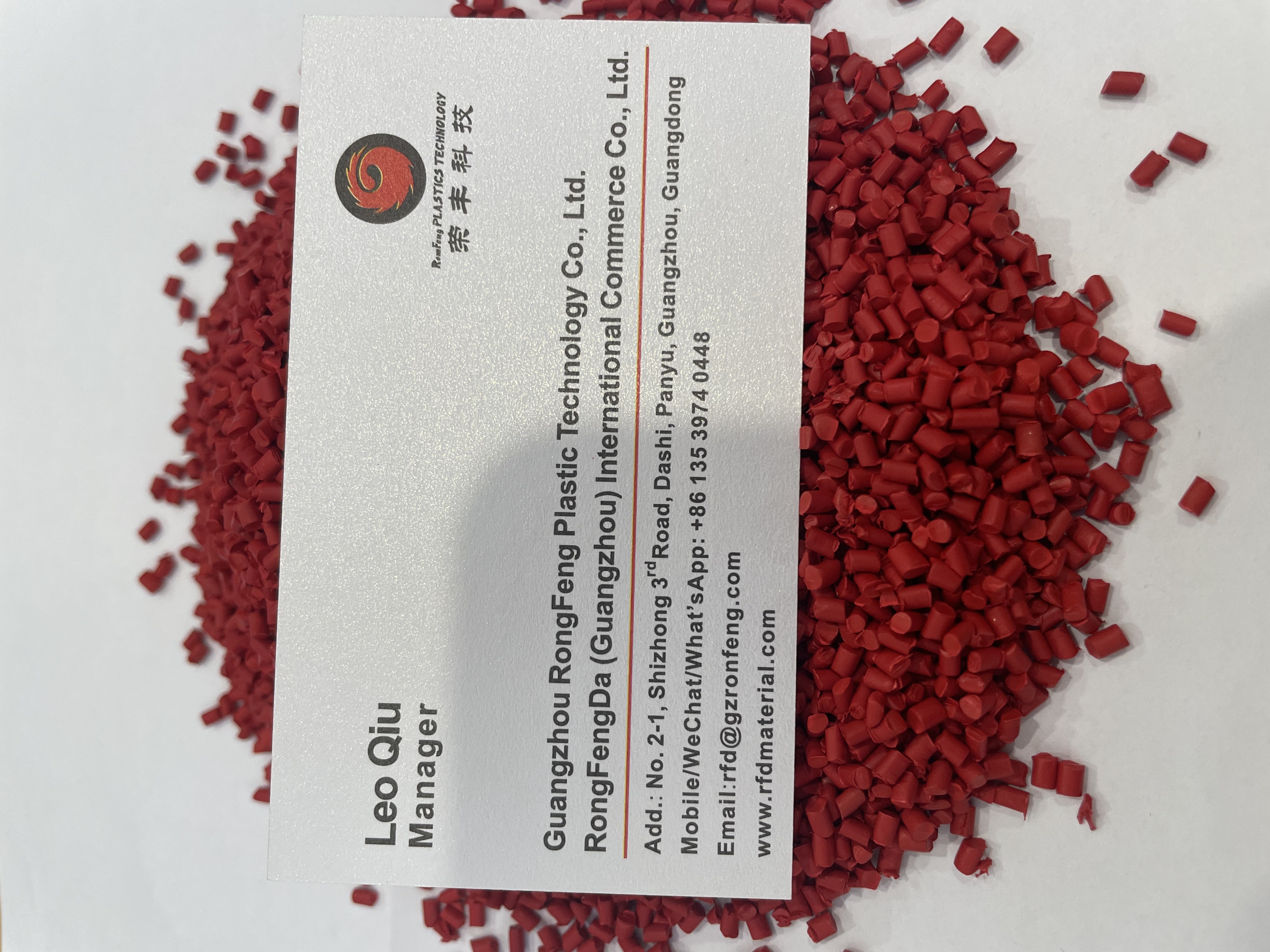

PET Color Masterbatch for Straps

PET masterbatch is a concentrated mixture of pigments or additives dispersed in a PET (Polyethylene Terephthalate) carrier resin. It is widely used in plastic manufacturing to provide consistent coloration and enhance material properties like UV resistance or flame retardancy. Compatible with PET-based products (e.g., bottles, fibers), it ensures uniform color distribution and high thermal stability during processing. Available in various formulations, it supports eco-friendly production by reducing waste and energy consumption compared to raw pigment use. Ideal for industries requiring precise, vibrant, and durable coloring solutions.

Categorize:

PET Masterbatch

Keyword:

**PET Color Masterbatch for Straps**

In the world of manufacturing, the choice of materials is crucial, especially when it comes to producing items that require both durability and aesthetic appeal. One such material that has gained significant attention is PET, or polyethylene terephthalate. This versatile polymer is widely used in various applications, including the production of straps for bags, belts, and other accessories. The integration of color masterbatch into PET straps not only enhances their visual appeal but also contributes to their overall performance and marketability.

**Understanding PET and Its Advantages**

Polyethylene terephthalate (PET) is a thermoplastic polymer that belongs to the polyester family. It is known for its excellent strength-to-weight ratio, chemical resistance, and ability to withstand various environmental conditions. These properties make PET an ideal choice for producing straps that require both flexibility and durability.

One of the primary advantages of using PET is its recyclability. As sustainability becomes increasingly important in manufacturing, PET stands out as an environmentally friendly option. Straps made from PET can be recycled, reducing waste and promoting a circular economy. Additionally, PET straps can be produced in a wide range of colors and finishes, allowing manufacturers to create products that meet specific aesthetic demands.

**What is Color Masterbatch?**

Color masterbatch is a concentrated mixture of pigments and additives that are used to color plastic materials during the manufacturing process. It is typically composed of a carrier resin, which can be the same type of plastic that is being colored. The masterbatch is added to the base resin in a specific ratio, allowing for uniform dispersion of color throughout the final product.

Using color masterbatch offers several advantages. First, it provides consistent color quality and intensity, ensuring that each batch of straps meets the desired specifications. Second, it simplifies the coloring process, reducing the need for complex equipment and labor-intensive procedures. Lastly, color masterbatch allows for greater flexibility in color selection, enabling manufacturers to respond quickly to market trends and consumer preferences.

**The Role of PET Color Masterbatch in Strap Production**

In the production of PET straps, the use of color masterbatch plays a pivotal role. By incorporating color masterbatch into the PET resin, manufacturers can achieve vibrant colors and consistent finishes that enhance the visual appeal of the straps. This is particularly important in industries such as fashion, where color and design are key factors in consumer purchasing decisions.

Moreover, the addition of color masterbatch can improve the physical properties of the straps. Certain pigments and additives can enhance UV resistance, making the straps more suitable for outdoor applications. Other additives may improve the strap's tensile strength or flexibility, further increasing its usability in various contexts.

**Customization and Market Trends**

One of the standout features of using PET color masterbatch for straps is the ability to customize colors to meet specific market demands. As consumer preferences shift, manufacturers can quickly adapt their product offerings by changing the color masterbatch used in production. This level of customization is essential in a fast-paced market where trends can change rapidly.

For instance, during fashion seasons, certain colors may become popular, prompting manufacturers to produce straps in those shades. By utilizing color masterbatch, manufacturers can respond swiftly to these trends, ensuring that their products remain relevant and appealing to consumers.

**Sustainability Considerations**

As the world becomes more environmentally conscious, the importance of sustainable practices in manufacturing cannot be overstated. PET itself is a recyclable material, and when combined with eco-friendly color masterbatch options, it can significantly reduce the environmental impact of strap production.

Some manufacturers are now exploring bio-based color masterbatches, which are derived from renewable resources. These innovations allow companies to produce straps that not only look good but also align with the growing demand for sustainable products. By choosing eco-friendly options, manufacturers can appeal to a broader audience and contribute to a more sustainable future.

**Conclusion**

The integration of PET color masterbatch in strap production represents a significant advancement in the manufacturing process. By enhancing the visual appeal, durability, and sustainability of PET straps, color masterbatch has become an essential component in meeting the demands of modern consumers. As trends continue to evolve, the ability to customize colors and improve product performance will keep manufacturers at the forefront of the industry.

In summary, PET color masterbatch not only adds aesthetic value to straps but also plays a crucial role in enhancing their physical properties and sustainability. As manufacturers continue to innovate and adapt to changing market demands, the use of PET color masterbatch will undoubtedly remain a key factor in the successful production of high-quality straps.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.