PRODUCTS

Laser Marking Additive Masterbatch for PP PE TPU ABS POM ASA

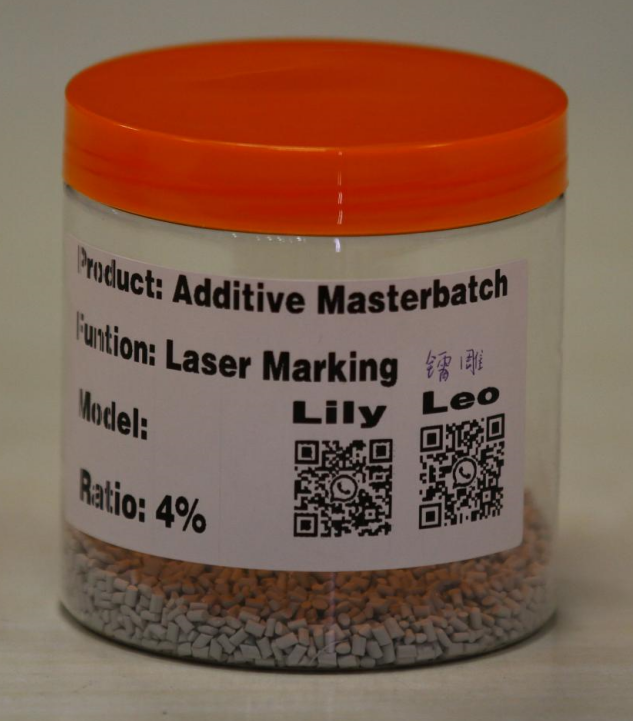

Laser marking masterbatch is a functional additive that enables high-contrast, permanent markings on plastics (e.g., PP, ABS, PC) when exposed to laser beams. It contains metal oxides (e.g., TiO₂) or mineral pigments that react to laser energy, creating dark/light traces without damaging the material. Key features: Precision: Supports fine details (≤0.1mm line width4) for barcodes, logos, or serial numbers. Durability: Resistant to abrasion, chemicals, and UV exposure. Eco-friendly: Halogen-free formulations comply with REACH/ROHS. Widely used in electronics, automotive parts, and medical devices for traceability. Dosage: 1-5% depending on substrate and laser type (fiber/CO₂).

Categorize:

Additive Masterbatch

Keyword:

**Laser Marking Additive Masterbatch for PP PE TPU ABS POM ASA**

In recent years, the demand for high-quality marking solutions in various industries has surged. The ability to mark products with precision and durability is essential for branding, traceability, and compliance with regulations. One innovative solution that has emerged in this space is the use of laser marking additive masterbatch for a range of thermoplastics, including polypropylene (PP), polyethylene (PE), thermoplastic polyurethane (TPU), acrylonitrile butadiene styrene (ABS), polyoxymethylene (POM), and acrylonitrile styrene acrylate (ASA). This article will explore the benefits, applications, and considerations of using laser marking additive masterbatch in these materials.

**Understanding Laser Marking Additive Masterbatch**

Laser marking additive masterbatch is a concentrated mixture of pigments and additives that can be incorporated into thermoplastic materials during the manufacturing process. This masterbatch is specifically designed to enhance the laser marking capabilities of the base polymers. When exposed to a laser, the masterbatch reacts to produce a high-contrast mark that is both permanent and resistant to wear and environmental factors. The technology offers a clean and efficient way to achieve high-quality markings without the need for inks or solvents.

**Benefits of Laser Marking Additive Masterbatch**

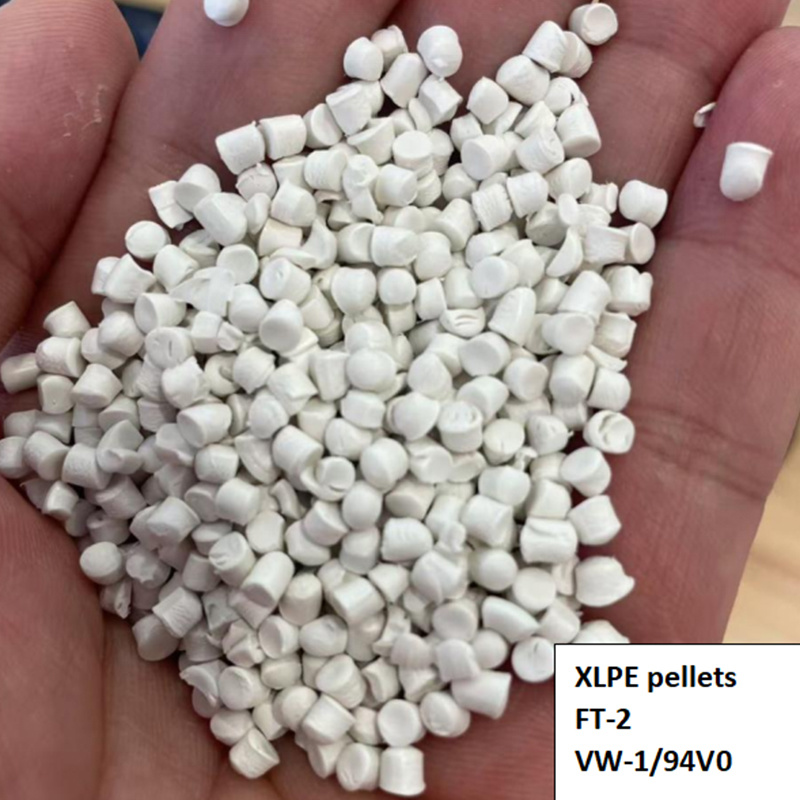

1. **Versatility Across Materials**: One of the primary advantages of laser marking additive masterbatch is its compatibility with various thermoplastics. Whether it is PP, PE, TPU, ABS, POM, or ASA, manufacturers can incorporate these additives to achieve optimal marking results. This versatility makes it an attractive option for companies producing diverse product lines.

2. **Durability and Resistance**: Laser markings created using additive masterbatches are highly durable. They can withstand exposure to harsh chemicals, UV light, and extreme temperatures, making them ideal for products that are used in challenging environments. This durability ensures that markings remain legible and intact throughout the product's lifecycle.

3. **Environmentally Friendly**: Unlike traditional marking methods that may require inks or solvents, laser marking with additive masterbatch is a cleaner and more environmentally friendly option. The process generates minimal waste and does not introduce harmful chemicals into the environment, aligning with the growing trend towards sustainability in manufacturing.

4. **Cost-Effectiveness**: By integrating laser marking additive masterbatch into the production process, companies can reduce costs associated with traditional marking methods. There is no need for additional equipment or materials, and the efficiency of the laser marking process can lead to faster production times.

**Applications in Various Industries**

The applications of laser marking additive masterbatch are vast and varied. Industries such as automotive, electronics, consumer goods, and medical devices benefit significantly from this technology.

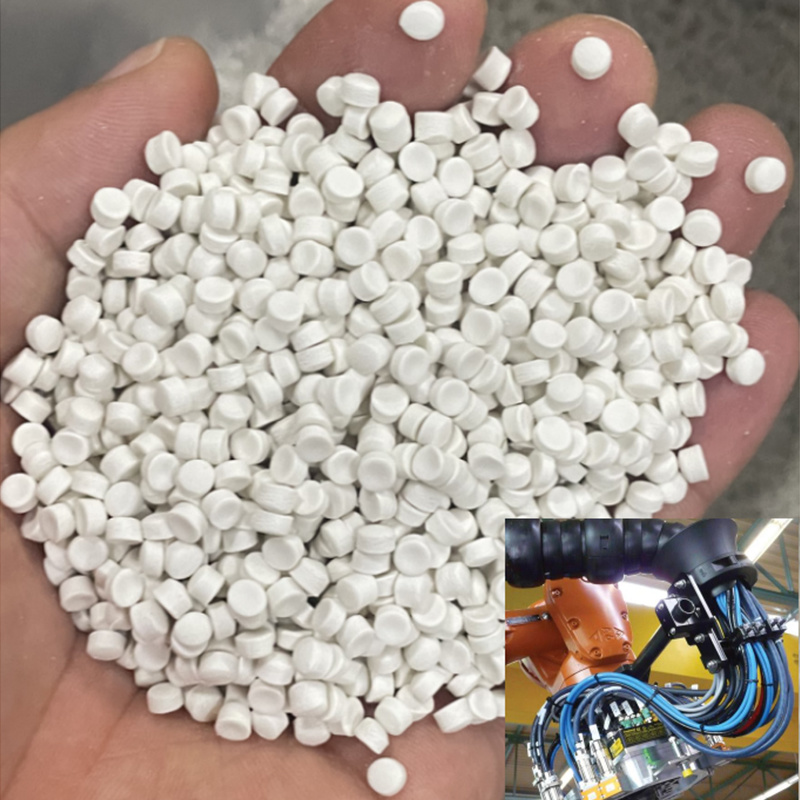

1. **Automotive Industry**: In the automotive sector, laser marking is essential for product identification, part traceability, and compliance with safety regulations. Markings on components such as dashboards, switches, and engine parts can be achieved using laser marking additive masterbatch, ensuring durability and clarity.

2. **Electronics**: The electronics industry relies on precise markings for branding, barcodes, and QR codes. Laser marking provides a clean and professional appearance, which is crucial for consumer perception. Additionally, the ability to mark small and intricate components without damaging them is a significant advantage.

3. **Consumer Goods**: Products ranging from packaging to household items often require markings for branding and information purposes. Laser marking additive masterbatch allows manufacturers to create high-quality marks that enhance product appeal while ensuring compliance with labeling regulations.

4. **Medical Devices**: In the medical field, traceability is of utmost importance. Laser markings on medical devices and packaging ensure that products can be tracked throughout their lifecycle. The durability of these markings is critical in maintaining compliance with industry standards.

**Considerations When Using Laser Marking Additive Masterbatch**

While the benefits of laser marking additive masterbatch are significant, there are several considerations that manufacturers should keep in mind:

1. **Material Compatibility**: Not all laser marking additives are compatible with every type of thermoplastic. It is essential to conduct thorough testing to ensure that the chosen masterbatch is suitable for the specific polymer being used.

2. **Laser Parameters**: Different lasers have varying capabilities and settings. Manufacturers must optimize laser parameters, such as power, speed, and frequency, to achieve the best marking results. This may require collaboration with laser equipment suppliers.

3. **Color and Contrast**: The color of the masterbatch can influence the contrast of the markings. Selecting the right color for the intended application is crucial for achieving high visibility and legibility.

4. **Regulatory Compliance**: For industries such as medical and food packaging, regulatory compliance is a critical factor. Manufacturers should ensure that the materials used in the masterbatch meet industry-specific standards and regulations.

**Conclusion**

Laser marking additive masterbatch presents a transformative solution for marking various thermoplastic materials, including PP, PE, TPU, ABS, POM, and ASA. Its versatility, durability, and environmentally friendly nature make it an attractive option for manufacturers across multiple industries. As technology continues to evolve, the integration of laser marking solutions will likely become even more prevalent, providing businesses with the ability to enhance product branding and traceability while maintaining compliance with industry standards. By understanding the benefits and considerations of laser marking additive masterbatch, manufacturers can make informed decisions that will contribute to their success in an increasingly competitive market.

Next

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.