PRODUCTS

TPE Color Masterbatch

TPE (Thermoplastic Elastomer) color masterbatch is a concentrated blend of pigments, additives, and a TPE-compatible carrier resin, used to impart precise, vibrant colors to TPE products. Combining thermoplastic processability with elastomeric flexibility, TPEs require specialized coloring solutions. The masterbatch ensures uniform dispersion, enhancing color consistency while maintaining mechanical properties like elasticity and durability. It simplifies processing via injection molding, extrusion, or blow molding, reducing equipment cleanup and material waste. Ideal for automotive components, consumer goods, medical devices, and packaging, it offers customization in hues and concentrations. Environmentally friendly, it supports recyclability and complies with low-VOC standards, balancing aesthetics with performance and sustainability.

Categorize:

TPU TPE Masterbatch

Keyword:

**TPE Color Masterbatch: An Essential Component in Modern Plastics**

Thermoplastic elastomers (TPE) have gained significant traction in various industries due to their unique combination of rubber-like elasticity and plastic-like processability. One of the key aspects that enhance the appeal of TPE materials is the use of color masterbatch. This article delves into what TPE color masterbatch is, its advantages, applications, and the future of this essential component in the world of plastics.

**Understanding TPE Color Masterbatch**

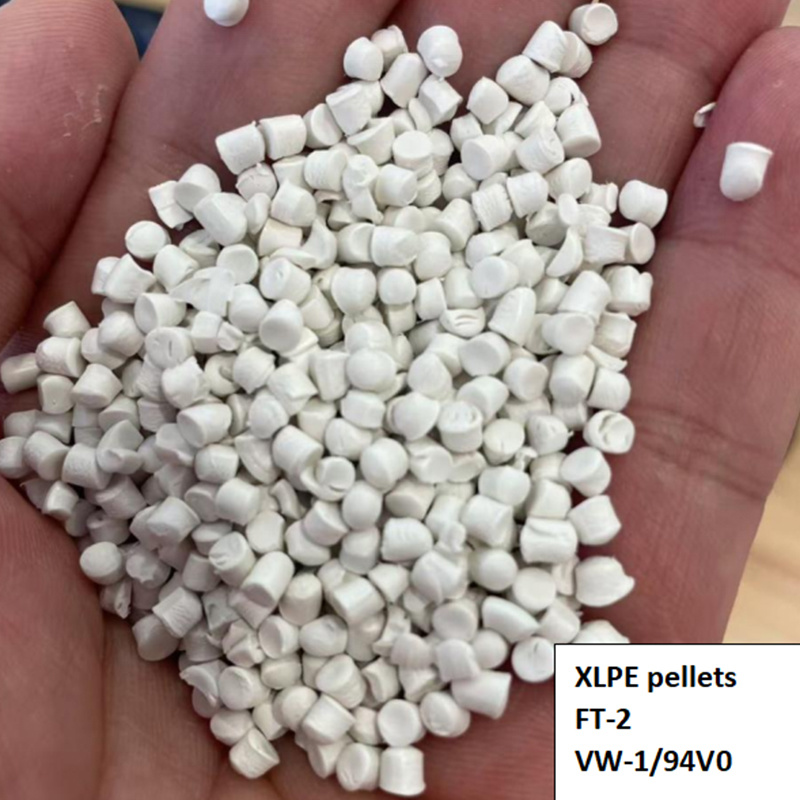

A color masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin, which is then used to color TPE products during the manufacturing process. The masterbatch allows for uniform dispersion of colorants throughout the TPE matrix, ensuring consistent color and performance. The incorporation of color masterbatch in TPE manufacturing is crucial for achieving the desired aesthetic and functional properties of the final product.

The process of creating a color masterbatch involves several stages, including pigment selection, formulation, and blending. High-quality pigments are chosen based on their compatibility with TPE, as well as their stability and resistance to fading. The selected pigments are then mixed with a carrier resin and subjected to heat and shear to create a uniform blend. This masterbatch can be easily incorporated into TPE during extrusion or injection molding, allowing for efficient and cost-effective production.

**Advantages of TPE Color Masterbatch**

1. **Color Consistency**: One of the primary advantages of using color masterbatch is the ability to achieve consistent color throughout the product. This uniformity is essential for maintaining brand identity and meeting customer expectations in various applications.

2. **Versatility**: TPE color masterbatch can be formulated in a wide range of colors, enabling manufacturers to produce products that meet specific aesthetic requirements. This versatility is particularly beneficial in industries such as automotive, consumer goods, and medical devices, where color differentiation is important.

3. **Improved Processing**: The use of color masterbatch simplifies the manufacturing process. It allows for easier handling and storage compared to liquid colorants, which can be prone to spills and contamination. Additionally, masterbatches can be tailored to improve the flow properties of TPE, enhancing processing efficiency.

4. **Enhanced Performance**: Many color masterbatches are formulated with additives that can improve the overall performance of TPE products. These additives may include UV stabilizers, antioxidants, and flame retardants, which contribute to the longevity and safety of the final product.

5. **Cost-Effectiveness**: By using color masterbatch, manufacturers can reduce waste and improve production efficiency. The concentrated nature of masterbatch means that only a small amount is needed to achieve the desired color, resulting in lower material costs and reduced environmental impact.

**Applications of TPE Color Masterbatch**

The versatility of TPE color masterbatch allows it to be used in a wide array of applications across various industries. Some notable applications include:

1. **Automotive Industry**: TPE is commonly used in automotive parts, such as seals, gaskets, and interior components. The use of color masterbatch enables manufacturers to produce visually appealing parts that enhance the overall aesthetics of vehicles while meeting stringent performance standards.

2. **Consumer Goods**: From toys to kitchenware, TPE color masterbatch is widely utilized in consumer goods. The ability to create vibrant and consistent colors makes TPE an attractive choice for manufacturers looking to differentiate their products in a competitive market.

3. **Medical Devices**: In the medical field, TPE is often used for applications requiring biocompatibility and sterilization. Color masterbatch can be employed to color-code medical devices for easy identification while ensuring that the performance characteristics of the TPE are not compromised.

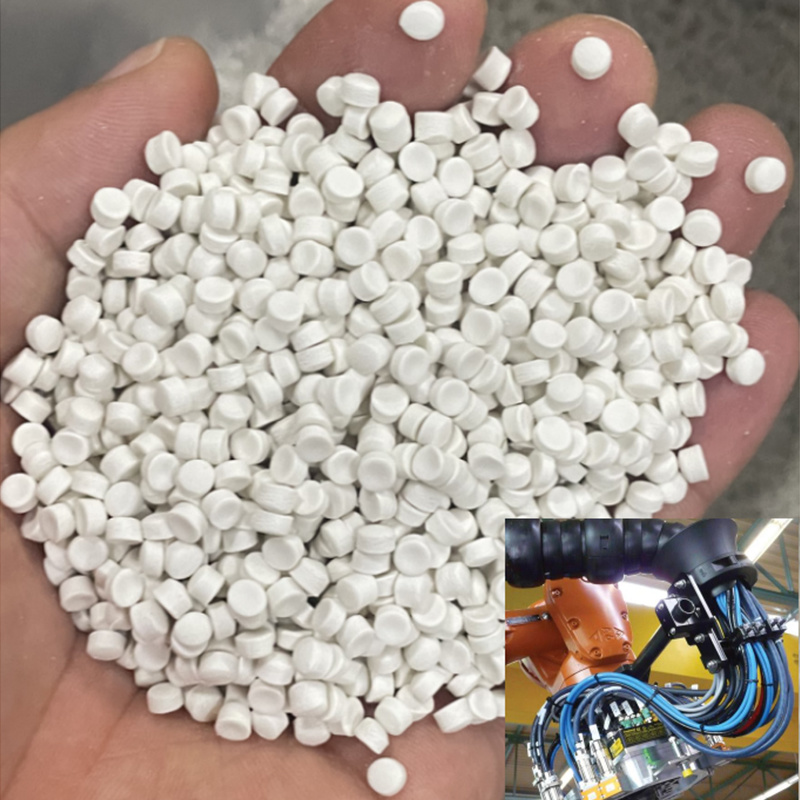

4. **Electronics**: TPE is increasingly used in the electronics industry for cable insulation and connectors. The incorporation of color masterbatch allows for easy identification of wires and components, enhancing safety and organization in electronic devices.

**The Future of TPE Color Masterbatch**

As the demand for TPE materials continues to grow, so does the importance of color masterbatch. The future of TPE color masterbatch will likely be shaped by several trends:

1. **Sustainability**: With an increasing focus on environmental responsibility, manufacturers are seeking sustainable alternatives in their production processes. The development of bio-based color masterbatches and recycling-friendly formulations will play a crucial role in the future of TPE colorants.

2. **Advanced Technology**: Innovations in pigment technology and masterbatch formulation are expected to enhance the performance and capabilities of TPE color masterbatch. This may include the development of new pigments that offer improved lightfastness, weather resistance, and functionality.

3. **Customization**: As consumer preferences evolve, the demand for customized solutions will rise. Manufacturers may increasingly turn to tailor-made color masterbatches that meet specific requirements, allowing for greater flexibility in product design and development.

4. **Regulatory Compliance**: As regulations surrounding materials used in various industries become more stringent, the need for compliant color masterbatches will grow. Manufacturers will need to ensure that their colorants meet safety and environmental standards, particularly in sectors such as food packaging and medical devices.

**Conclusion**

TPE color masterbatch plays a vital role in the modern plastics industry, offering numerous advantages such as color consistency, versatility, and improved processing. Its applications span across various sectors, including automotive, consumer goods, medical devices, and electronics. As the industry continues to evolve, the future of TPE color masterbatch will be driven by sustainability, advanced technology, customization, and regulatory compliance. Embracing these trends will not only enhance the performance and appeal of TPE products but also contribute to a more sustainable and innovative future in plastics.

Next

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.