PRODUCTS

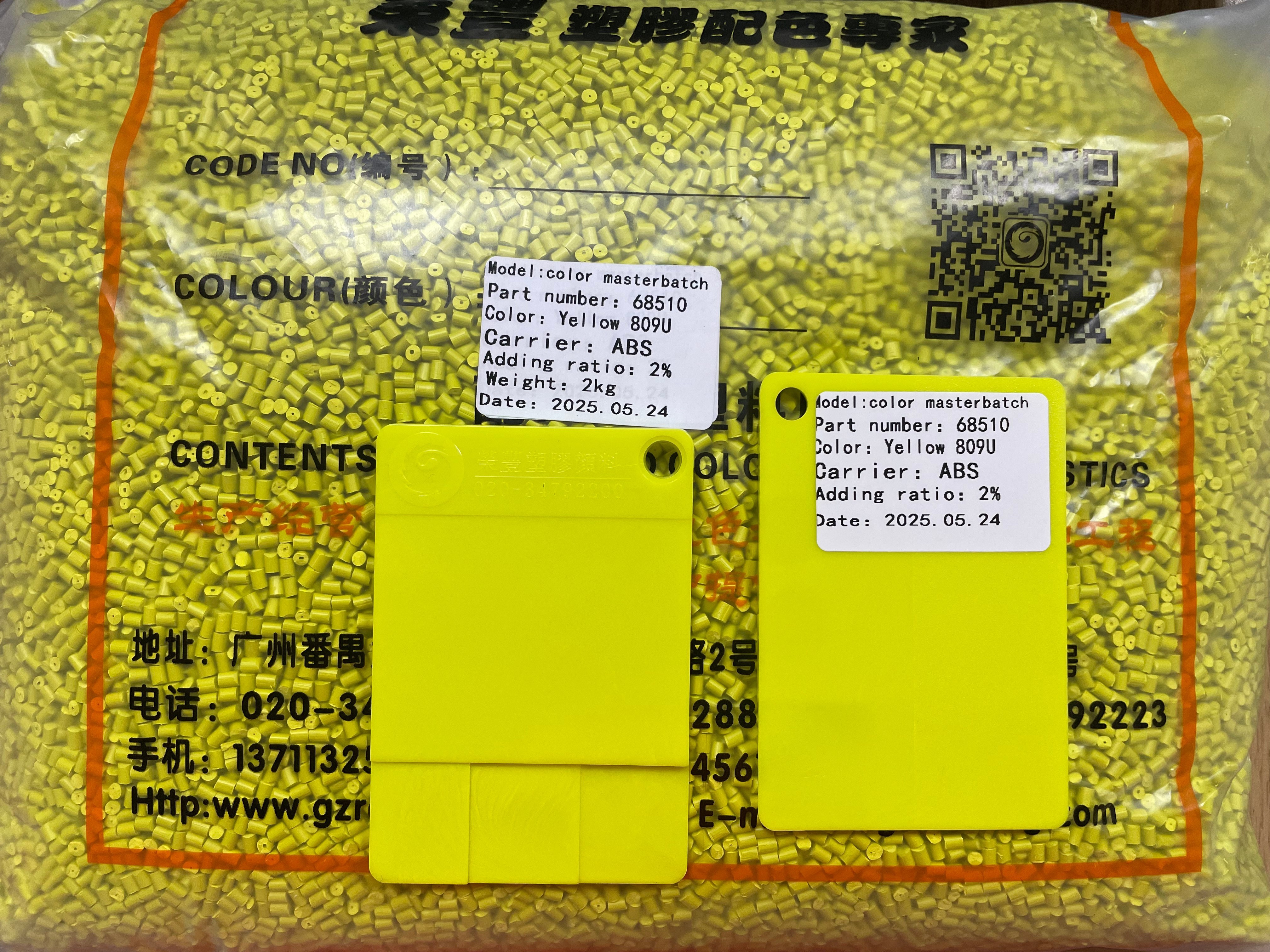

ABS Color Masterbatch

ABS Color Masterbatch is a concentrated pigment blend designed to color Acrylonitrile Butadiene Styrene (ABS) polymers. Composed of an ABS-compatible carrier resin, high-quality pigments, and additives, it ensures even dispersion during processing. Suitable for injection molding, extrusion, and blow molding, it delivers vibrant, consistent colors while preserving ABS’s mechanical properties, such as impact resistance, rigidity, and thermal stability. Customizable formulations can enhance UV resistance, flame retardancy, or anti-static performance. Widely used in automotive parts, electronics housings, toys, and appliances, ABS masterbatch offers cost-efficient, eco-friendly coloring. Its precise formulation withstands ABS’s processing temperatures (200–240°C), ensuring stability and compatibility, reducing waste, and meeting demands for aesthetics and functionality in high-performance applications.

Categorize:

ABS Masterbatch

Keyword:

**ABS Color Masterbatch**

In the world of plastics, color plays a crucial role in the aesthetics and functionality of various products. One of the most significant advancements in this area is the development of ABS color masterbatch. This article delves into what ABS color masterbatch is, its composition, advantages, applications, and its importance in the manufacturing industry.

**Understanding ABS Color Masterbatch**

ABS, or Acrylonitrile Butadiene Styrene, is a popular thermoplastic known for its strength, durability, and impact resistance. It is widely used in various applications, from automotive parts to consumer electronics. However, the natural color of ABS is typically off-white or beige, which may not be suitable for many applications. This is where color masterbatch comes into play.

Color masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin. In the case of ABS color masterbatch, the carrier resin is ABS itself. This allows manufacturers to add vibrant colors to their ABS products without compromising the material's properties. The masterbatch can be easily mixed with natural ABS during the manufacturing process, providing a uniform color throughout the final product.

**Composition of ABS Color Masterbatch**

The composition of ABS color masterbatch primarily includes three components: pigments, carrier resin, and additives.

1. **Pigments**: These are the coloring agents responsible for the hue and shade of the final product. They can be organic or inorganic, depending on the desired color and performance characteristics. The choice of pigment can also affect the product's UV resistance, thermal stability, and opacity.

2. **Carrier Resin**: In ABS color masterbatch, the carrier resin is ABS itself. This ensures compatibility with the final product, as the masterbatch needs to blend seamlessly with the natural ABS resin during processing.

3. **Additives**: Various additives can be included in the masterbatch to enhance specific properties of the final product. These may include UV stabilizers, anti-oxidants, and processing aids, which improve the durability and processing characteristics of the ABS material.

**Advantages of ABS Color Masterbatch**

There are several advantages to using ABS color masterbatch in manufacturing processes:

1. **Cost-Effectiveness**: Using masterbatch allows manufacturers to achieve the desired color without needing to dye the entire resin. This can lead to significant cost savings, especially in large-scale production.

2. **Consistency and Quality**: Masterbatches provide uniform color distribution, ensuring that every product maintains the same hue. This consistency is crucial for branding and consumer satisfaction.

3. **Ease of Use**: ABS color masterbatch is easy to handle and mix. Manufacturers can simply add the masterbatch to the natural ABS during the compounding process, simplifying the production workflow.

4. **Enhanced Properties**: The inclusion of specific additives in the masterbatch can improve the overall performance of the ABS material, making it more resistant to UV light, heat, and other environmental factors.

**Applications of ABS Color Masterbatch**

ABS color masterbatch finds applications in various industries, including:

1. **Automotive**: The automotive industry uses ABS for various components, such as dashboards, trim, and exterior parts. The ability to achieve vibrant colors and finishes enhances the aesthetic appeal of vehicles.

2. **Consumer Electronics**: Products like televisions, computers, and mobile devices often utilize ABS for their casings. Color masterbatch allows manufacturers to create visually appealing products that stand out in the market.

3. **Household Goods**: From kitchen appliances to furniture, ABS color masterbatch is used to produce a wide range of household items, providing both functionality and style.

4. **Toys**: The toy industry benefits significantly from ABS color masterbatch, as it allows for bright, attractive colors that appeal to children and parents alike.

**Environmental Considerations**

As sustainability becomes increasingly important in manufacturing, the plastic industry is also adapting. ABS color masterbatch can be produced with eco-friendly pigments and additives, reducing the environmental impact of plastic products. Moreover, the ability to create vibrant colors without extensive processing can lead to lower energy consumption and waste generation.

**Conclusion**

ABS color masterbatch is a vital component in the production of colored ABS products, offering numerous advantages such as cost-effectiveness, consistency, and enhanced properties. Its wide range of applications across various industries highlights its importance in modern manufacturing. As the demand for sustainable and visually appealing products continues to grow, ABS color masterbatch will undoubtedly play a significant role in shaping the future of plastic manufacturing. By understanding its composition and benefits, manufacturers can leverage this technology to enhance their products and meet the evolving needs of consumers.

Next

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.