PRODUCTS

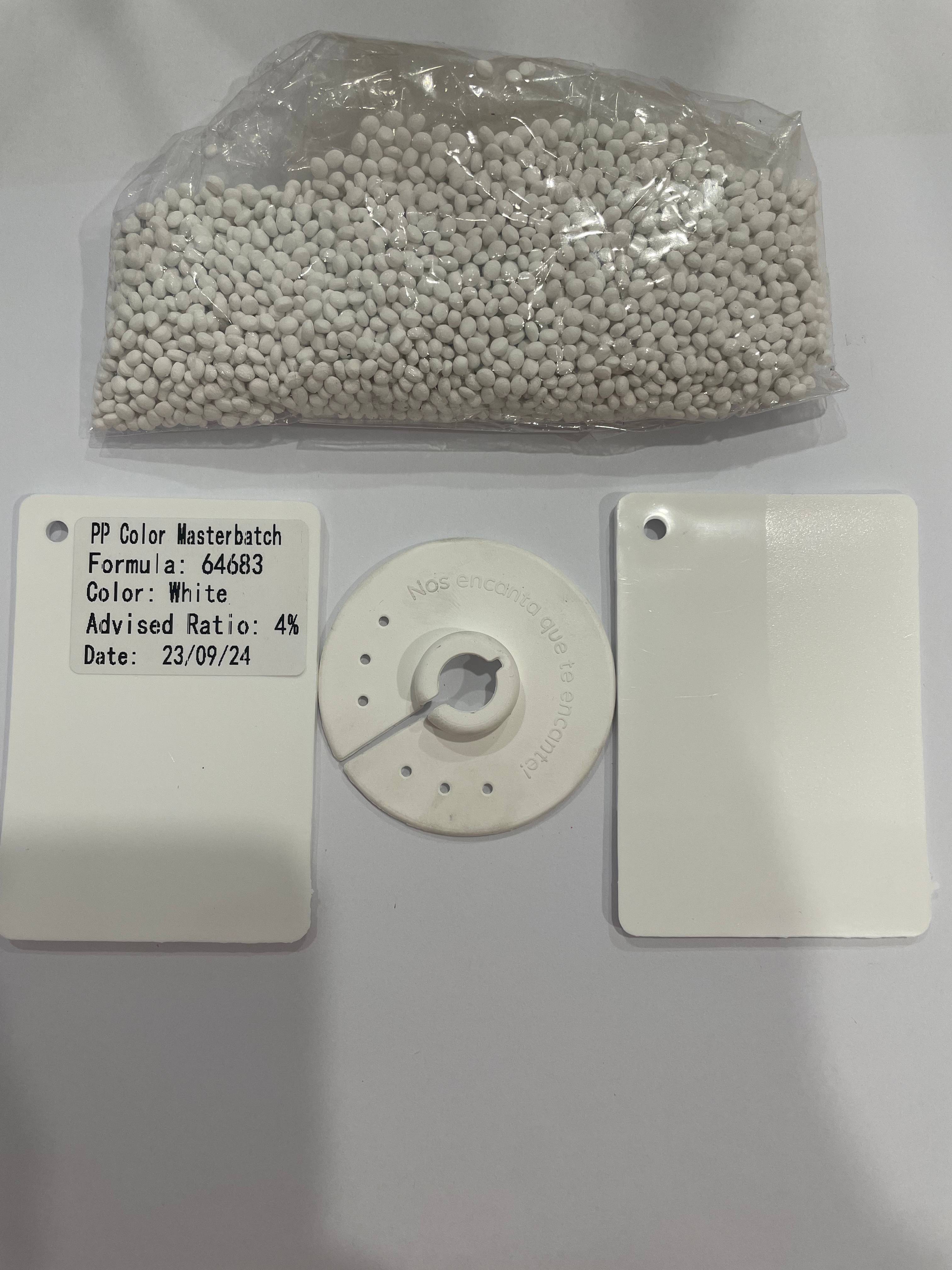

PP Color Masterbatch Food Grade

PP Color Masterbatch It is a concentrated pigment mixture in a polypropylene (PP) carrier resin, designed for uniform coloration of PP-based products. The masterbatch ensures excellent dispersion and heat resistance, leveraging PP's thermal stability up to high processing temperatures. Key applications include wire insulation and packaging materials, where it enhances aesthetics without compromising durability. Advantages include compatibility with PP's mechanical strength and chemical resistance for long-lasting performance.

Categorize:

PP Mastebatch

Keyword:

**PP Color Masterbatch Food Grade**

In the world of plastics, color masterbatches have become an essential component for manufacturers aiming to enhance the aesthetic appeal and functionality of their products. Among the various types of masterbatches, PP (Polypropylene) Color Masterbatch Food Grade stands out due to its specific applications in food packaging and other related sectors. This article delves into the characteristics, applications, and advantages of PP Color Masterbatch Food Grade, emphasizing its significance in the food industry.

**Understanding PP Color Masterbatch**

PP Color Masterbatch is a concentrated mixture of pigments and additives encapsulated in a polypropylene carrier resin. It is designed to impart color to polypropylene products while ensuring compatibility with the polymer matrix. The term "food grade" indicates that the masterbatch meets stringent safety and regulatory standards for materials that come into contact with food. This compliance is crucial for manufacturers looking to produce safe and reliable packaging solutions.

**Characteristics of PP Color Masterbatch Food Grade**

1. **Safety and Compliance**: The primary characteristic of food-grade masterbatches is their adherence to safety regulations. These products are formulated using non-toxic, FDA-approved pigments and additives, ensuring they do not leach harmful substances into food products. Compliance with international standards such as EU regulations and FDA guidelines is essential for manufacturers in the food sector.

2. **Color Consistency**: PP Color Masterbatch provides excellent color consistency and dispersion. This quality is vital for achieving uniformity in product appearance, which is particularly important in consumer-facing applications like food packaging. The use of high-quality pigments ensures that the colors remain vibrant and do not fade over time.

3. **Processing Efficiency**: The masterbatch is designed for easy incorporation into the polypropylene matrix during the extrusion or injection molding process. Its compatibility with polypropylene allows for seamless processing, reducing downtime and improving overall production efficiency.

4. **Heat Stability**: Food-grade PP Color Masterbatch exhibits excellent thermal stability, which is crucial during processing at high temperatures. This property ensures that the color remains intact and does not degrade during the manufacturing process.

**Applications of PP Color Masterbatch Food Grade**

PP Color Masterbatch Food Grade finds applications in various sectors, particularly in food packaging. Some of the key applications include:

1. **Food Packaging**: One of the most significant uses of PP Color Masterbatch is in the production of food packaging materials. From containers to films, the masterbatch allows manufacturers to create visually appealing packaging that can attract consumers while ensuring the safety of the food inside.

2. **Bottles and Jars**: Many food products are packaged in polypropylene bottles and jars. Using food-grade color masterbatch enables manufacturers to produce colorful, eye-catching containers that enhance brand visibility and consumer appeal.

3. **Utensils and Cutlery**: Disposable utensils and cutlery made from polypropylene can also benefit from the use of PP Color Masterbatch. The addition of color can improve the overall dining experience while maintaining compliance with food safety standards.

4. **Caps and Closures**: The caps and closures of food containers can be customized using color masterbatches, providing a cohesive look to the packaging while ensuring that the products remain safe and secure.

**Advantages of Using PP Color Masterbatch Food Grade**

1. **Enhanced Aesthetics**: The use of color masterbatch allows manufacturers to create visually appealing products that can differentiate their offerings in a competitive market. Attractive packaging can significantly influence consumer purchasing decisions.

2. **Cost-Effectiveness**: Utilizing color masterbatch can be a cost-effective solution for manufacturers. It reduces the need for extensive pigment mixing and handling, streamlining the production process and lowering costs associated with raw materials.

3. **Versatility**: PP Color Masterbatch is versatile and can be tailored to meet specific requirements, such as different shades, effects, and functionalities. This adaptability allows manufacturers to innovate and develop new products that meet evolving consumer preferences.

4. **Environmental Considerations**: Many manufacturers are increasingly focused on sustainability. PP Color Masterbatch can be produced with eco-friendly additives and pigments, enabling companies to create products that align with environmental goals.

**Conclusion**

In summary, PP Color Masterbatch Food Grade plays a pivotal role in the food packaging industry, offering manufacturers a reliable solution for achieving vibrant colors while adhering to safety standards. Its characteristics, including safety, processing efficiency, and heat stability, make it an ideal choice for a variety of applications. As consumer demand for attractive and safe packaging continues to grow, the importance of PP Color Masterbatch Food Grade will undoubtedly increase, driving innovation and quality in the food packaging sector. By leveraging the advantages of this product, manufacturers can enhance their offerings and contribute to a more visually appealing and safer food supply chain.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.