PRODUCTS

Color Masterbatch for HIPS GPPS

Color masterbatches for GPPS (General Purpose Polystyrene) and HIPS (High Impact Polystyrene) provide precise, consistent coloration for these widely used styrenics. Key considerations include: Low-Processing Temperature Compatibility: Must disperse effectively and color uniformly at typical GPPS/HIPS processing temps (180-250°C) without degradation or causing plate-out. Optical Integrity (GPPS): Especially critical for transparent/translucent GPPS applications; pigments must avoid haze or clarity loss. Impact Modifier Compatibility (HIPS): Must not interfere with HIPS's rubber toughening system or negatively affect mechanical properties. Solvent/Migration Resistance: Essential for applications like food packaging, electronics, or medical parts exposed to chemicals. Electrical Neutrality: Critical for components requiring specific dielectric properties. Excellent dispersion ensures aesthetic quality and performance.

Categorize:

PS Masterbatch

Keyword:

**Color Masterbatch for HIPS GPPS**

Color masterbatch has become an integral part of the plastics industry, particularly in enhancing the visual appeal and performance of materials like High Impact Polystyrene (HIPS) and General Purpose Polystyrene (GPPS). This article explores the significance of color masterbatch in these materials, the production process, benefits, and the various applications in which they are utilized.

HIPS and GPPS are two types of polystyrene widely used in various applications due to their favorable properties. HIPS is known for its high impact resistance and toughness, making it suitable for products that require durability. GPPS, on the other hand, is characterized by its clarity and rigidity, often used in applications where transparency is essential. However, both materials typically start as a natural, colorless polymer. This is where color masterbatch comes into play, providing an efficient solution to achieve the desired colors without compromising the inherent properties of the base materials.

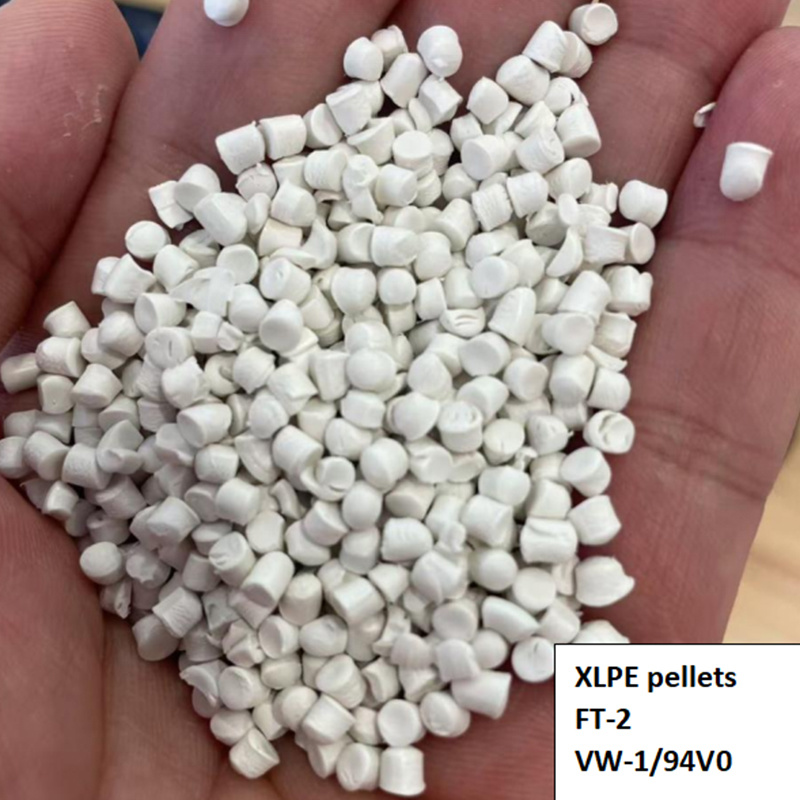

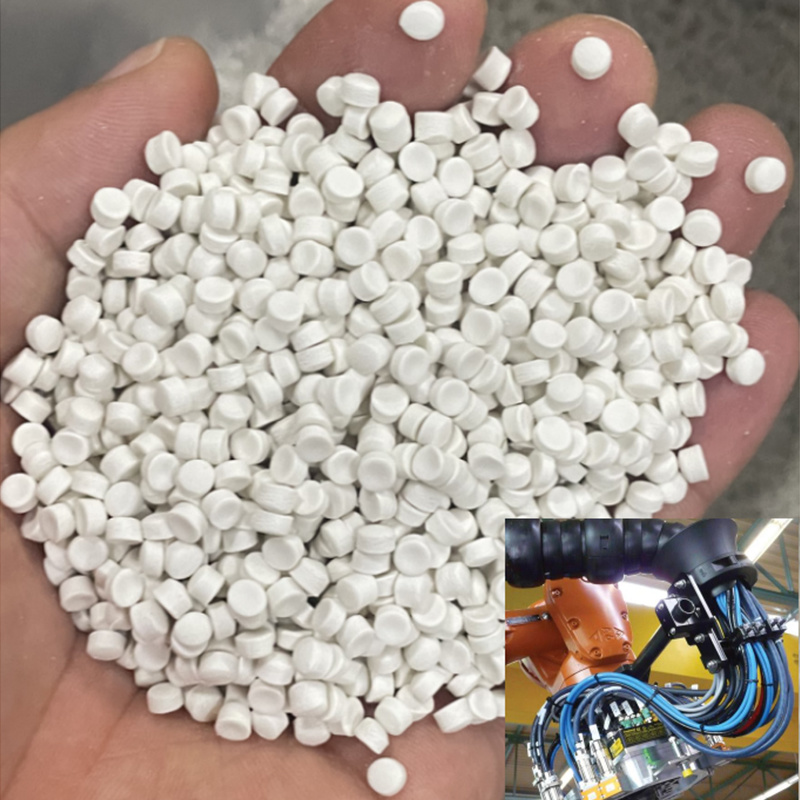

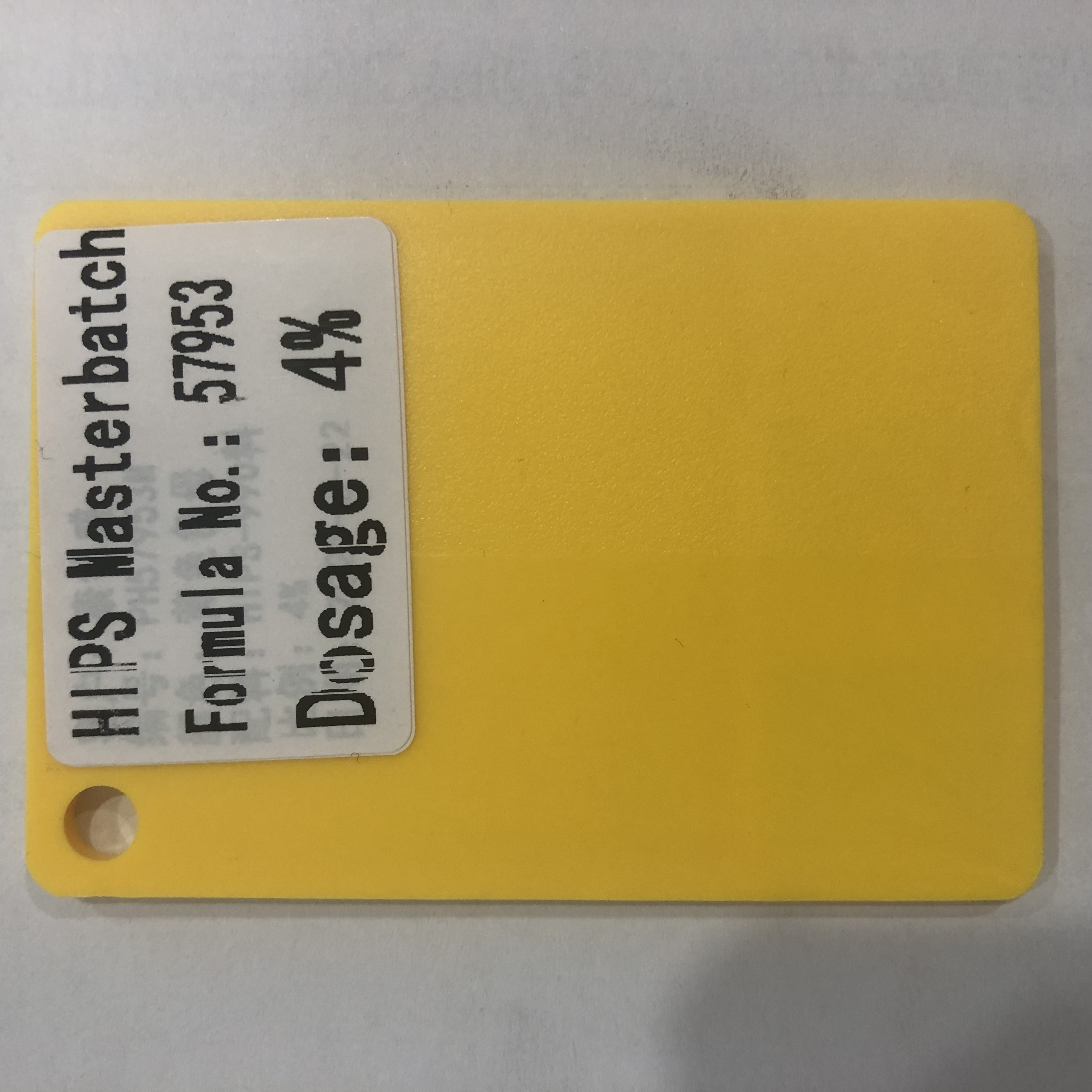

The production of color masterbatch involves the dispersion of pigments or dyes in a polymer carrier, which is then compounded into granules. This process ensures that the colorants are evenly distributed throughout the masterbatch, allowing for consistent coloring when mixed with HIPS or GPPS during processing. The choice of pigments is critical, as they must be compatible with the base polymers to prevent issues such as bleeding or fading. Moreover, the masterbatch must be formulated to withstand the processing conditions of HIPS and GPPS, which typically involve high temperatures.

One of the primary advantages of using color masterbatch in HIPS and GPPS is the efficiency it offers in the coloring process. Instead of adding pigments directly to the polymer, manufacturers can simply mix the masterbatch with the base material during extrusion or injection molding. This not only simplifies the production process but also minimizes the risk of contamination and ensures a cleaner working environment. Additionally, using masterbatch allows for better control over the color concentration, enabling manufacturers to achieve the precise shade they desire.

Another significant benefit of color masterbatch is its contribution to the overall performance of HIPS and GPPS products. Certain colorants can enhance specific properties of the polymers, such as UV stability, heat resistance, and even antibacterial effects. For example, incorporating UV stabilizers into the color masterbatch can significantly improve the outdoor durability of HIPS products, making them suitable for applications in harsh environments. Similarly, antibacterial additives can be included in the masterbatch for GPPS products used in medical or food-related applications, ensuring compliance with health standards.

Color masterbatch also plays a crucial role in branding and marketing. In a competitive market, the visual appeal of a product can significantly influence consumer choice. Using vibrant and consistent colors can help establish a brand identity and attract customers. Manufacturers can leverage color masterbatch to create unique and eye-catching designs, thereby differentiating their products from competitors. The flexibility of color masterbatch allows for easy adjustments to colors and effects, enabling quick responses to market trends and customer preferences.

Furthermore, sustainability has become a pressing concern in the plastics industry. Color masterbatch manufacturers are increasingly focusing on developing eco-friendly solutions. This includes using biodegradable or recycled materials for the masterbatch carrier and pigments. By adopting sustainable practices, companies can not only reduce their environmental impact but also appeal to a growing segment of environmentally conscious consumers.

In terms of applications, color masterbatch for HIPS and GPPS is used in a wide range of products. HIPS is commonly used in consumer goods, such as toys, kitchenware, and electronic housings, where color is vital for aesthetics and branding. GPPS is often found in packaging materials, display items, and various household products, where clarity and color play a crucial role in consumer attraction. The versatility of color masterbatch allows for innovative designs and solutions across different industries, from automotive to healthcare.

In conclusion, color masterbatch is an essential component in the processing of HIPS and GPPS, providing a myriad of benefits that enhance both the aesthetic and functional properties of these materials. From improving production efficiency to enabling sustainable practices, color masterbatch contributes significantly to the versatility and appeal of polystyrene products. As the demand for innovative and visually appealing products continues to rise, the role of color masterbatch in the plastics industry will only become more pronounced, driving advancements and creativity in material design and application.

Next

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.