PRODUCTS

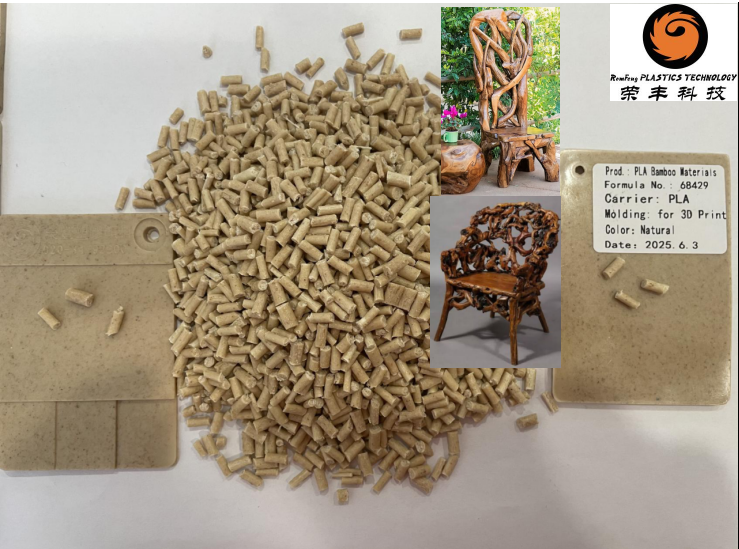

PLA Bamboo Fiber Modified Materials for 3D Print Furniture

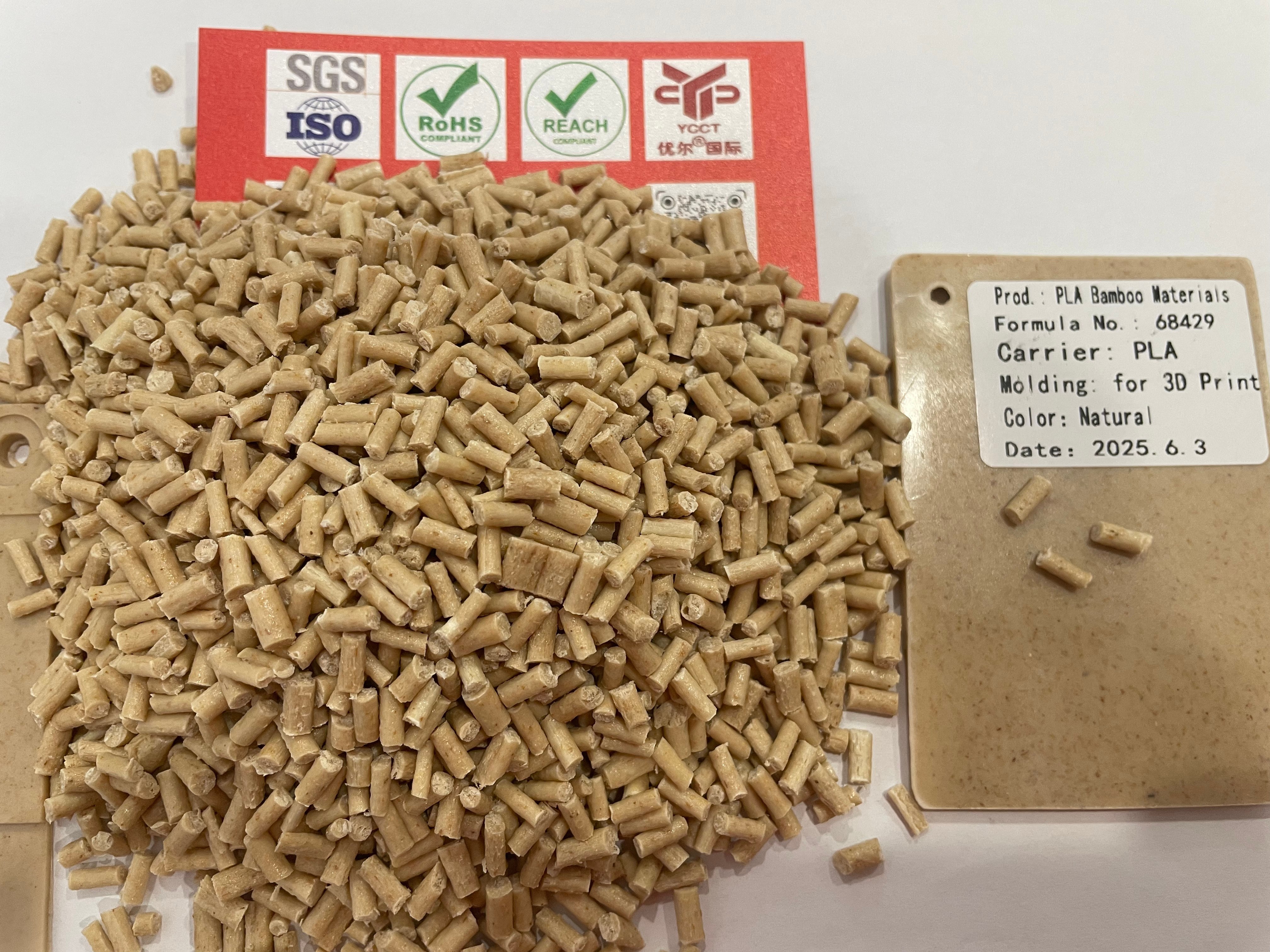

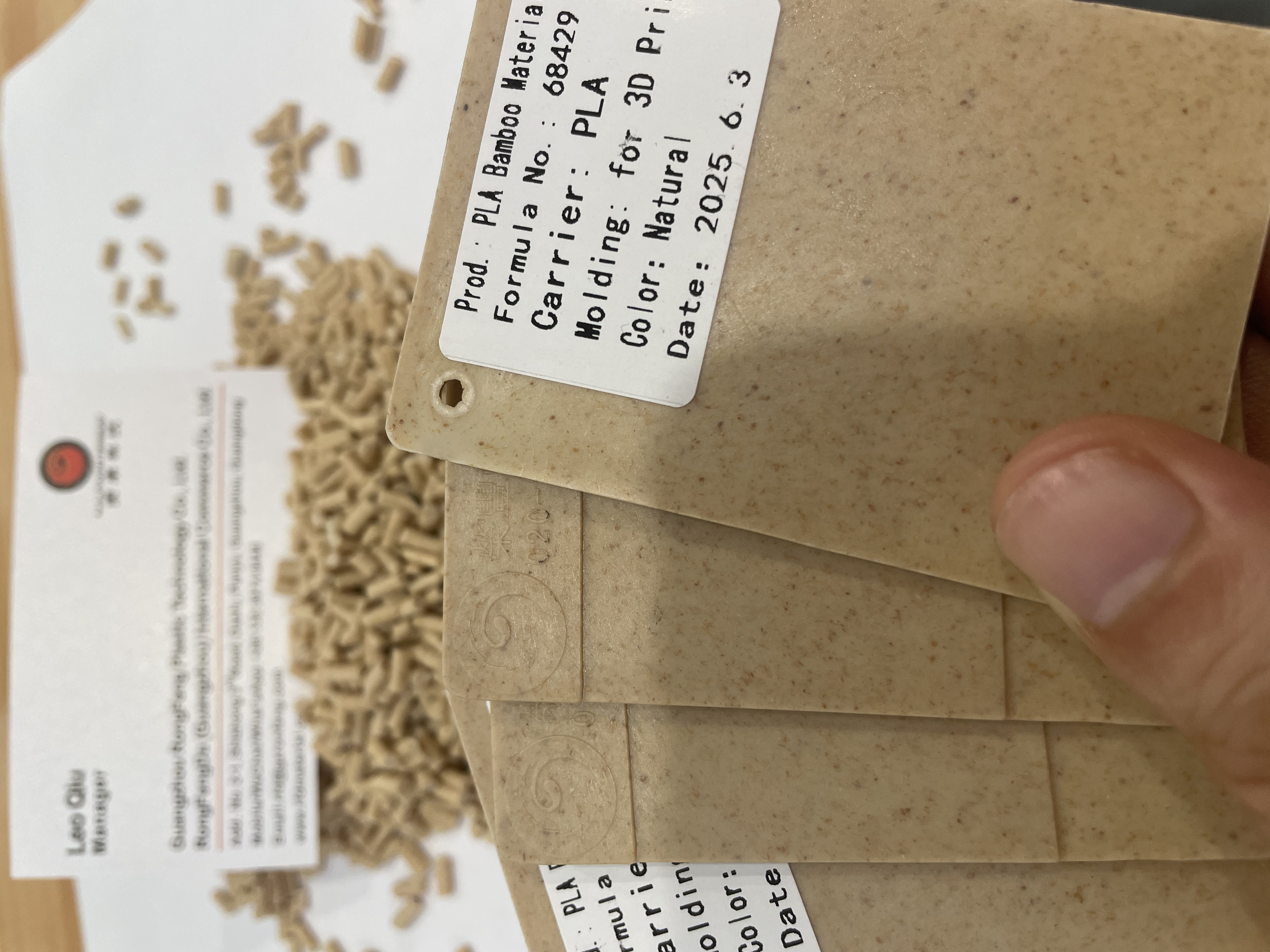

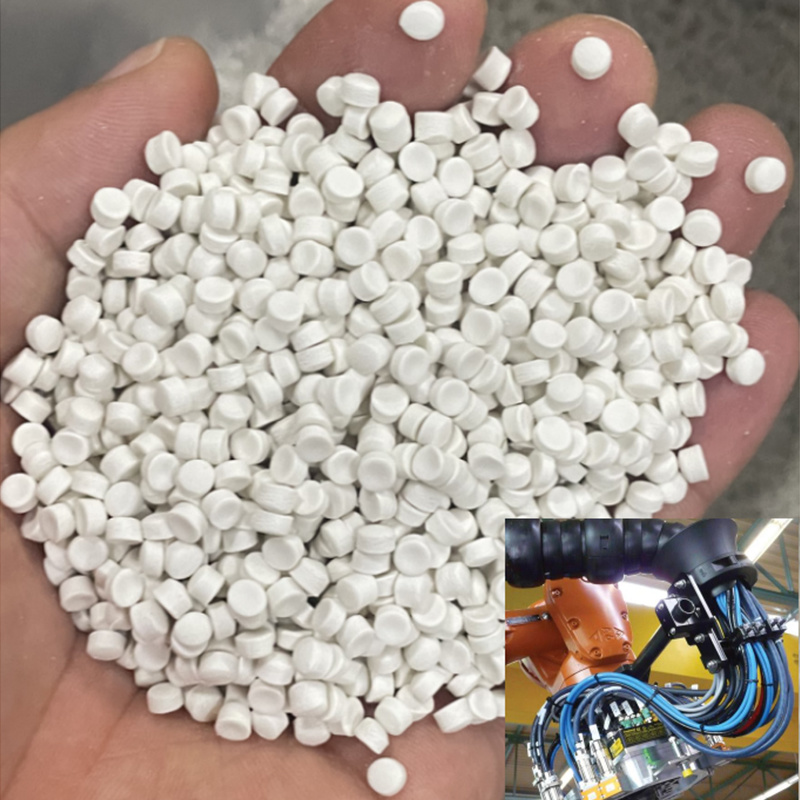

PLA bamboo fiber modified materials represent an eco-friendly innovation for 3D-printed furniture. By blending biodegradable polylactic acid (PLA) with natural bamboo fibers, this composite enhances mechanical strength, thermal stability, and texture while maintaining sustainability. The bamboo fibers act as a renewable reinforcement, reducing PLA’s brittleness and improving load-bearing capacity—ideal for furniture applications. 3D printing allows intricate, customizable designs with minimal waste. This material combination also offers a wood-like aesthetic, appealing to eco-conscious consumers. Research shows optimal fiber ratios (10–30%) balance durability and printability. As a low-carbon alternative to traditional plastics, PLA-bamboo composites align with circular economy goals, making them promising for future sustainable furniture production.

Categorize:

Bio Plastic

Keyword:

Title: PLA Bamboo Fiber Modified Materials for 3D Print Furniture

The evolution of 3D printing technology has transformed various industries, including furniture design and manufacturing. One of the most exciting developments in this field is the use of modified materials that enhance the properties of traditional 3D printing filaments. Among these innovations, PLA (Polylactic Acid) modified with bamboo fiber stands out due to its eco-friendliness, mechanical strength, and aesthetic appeal. This article explores the benefits, applications, and future potential of PLA bamboo fiber modified materials for 3D printed furniture.

The use of PLA as a base material in 3D printing is well-established. PLA is a biodegradable thermoplastic made from renewable resources such as corn starch or sugarcane. Its popularity stems from its ease of use, low melting point, and minimal warping during the printing process. However, while PLA offers several advantages, it also has limitations in terms of strength and durability. This is where bamboo fiber modification comes into play. By incorporating bamboo fibers into the PLA matrix, manufacturers can create a composite material that retains the benefits of PLA while significantly enhancing its mechanical properties.

One of the primary advantages of PLA bamboo fiber modified materials is their improved strength and stiffness. The addition of bamboo fibers reinforces the PLA structure, resulting in a composite that can withstand greater stress and strain. This characteristic is particularly beneficial for furniture applications, where items are subject to weight and usage over time. Moreover, the natural fibers provide a unique texture and appearance, allowing designers to create aesthetically pleasing pieces that resonate with the growing trend of sustainable design.

In addition to mechanical enhancements, PLA bamboo fiber modified materials offer excellent thermal stability. This property allows furniture made from these composites to maintain their shape and integrity under varying environmental conditions. Traditional PLA can soften at elevated temperatures, limiting its use in certain applications. However, the bamboo fiber reinforcement increases the thermal resistance of the composite, making it suitable for indoor and outdoor furniture alike. This versatility opens up new possibilities for designers and manufacturers, as they can create durable pieces that withstand the rigors of everyday use.

Sustainability is a critical consideration in today's design landscape. The integration of bamboo fibers into PLA not only enhances the material's performance but also contributes to environmental sustainability. Bamboo is a rapidly renewable resource that grows quickly and requires minimal water and pesticides. By using bamboo fibers, manufacturers can reduce their reliance on non-renewable resources and lower their carbon footprint. Furthermore, the biodegradability of PLA ensures that products made from this composite material will not contribute to long-term waste, aligning with the principles of a circular economy.

The applications of PLA bamboo fiber modified materials in furniture design are vast and varied. From chairs and tables to decorative items and storage solutions, the potential for innovation is immense. Designers can experiment with different ratios of PLA and bamboo fiber to achieve desired properties, such as flexibility, strength, and texture. Additionally, the ability to 3D print complex geometries allows for the creation of unique and intricate designs that would be challenging to produce using traditional manufacturing methods.

Despite the numerous advantages, there are challenges associated with the use of PLA bamboo fiber modified materials in 3D printing. One significant issue is the consistency of the material properties, which can vary based on the quality and processing of the bamboo fibers. Manufacturers must ensure that the bamboo fibers are properly treated and processed to achieve uniformity in the final product. Additionally, the printing parameters, such as temperature and speed, may need to be adjusted to accommodate the unique characteristics of the composite material.

Looking ahead, the future of PLA bamboo fiber modified materials in 3D printed furniture is promising. As technology advances, we can expect further improvements in material formulations and printing techniques. Research and development efforts will likely focus on optimizing the properties of the composite, enhancing its performance while maintaining its sustainable attributes. Moreover, as consumers increasingly prioritize eco-friendly products, the demand for sustainable furniture solutions will continue to rise, driving innovation in this space.

In conclusion, PLA bamboo fiber modified materials represent a significant advancement in the field of 3D printed furniture. With their enhanced mechanical properties, thermal stability, and sustainable characteristics, these composites offer a compelling alternative to traditional materials. As designers and manufacturers embrace this innovative approach, we can anticipate a new wave of furniture that not only meets the demands of modern consumers but also contributes to a more sustainable future. The journey of PLA bamboo fiber modified materials is just beginning, and their potential to revolutionize furniture design is limited only by our imagination.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.