PRODUCTS

FEP ETFE Color Masterbatch for Wires and Cables

FEP and ETFE color masterbatches are essential for wire and cable insulation, offering high-temperature resistance, superior electrical properties, and chemical inertness to withstand demanding environments like industrial and automotive applications. Key requirements include tailoring formulations to specific insulation needs, such as heat endurance and processing dynamics, ensuring pigments maintain performance under extreme conditions without degradation. FEP features a melting point around 304°C and density of 2.15 g/cc, while ETFE operates effectively from -65°C to 150°C with high tensile strength and low flammability for enhanced safety. Advanced masterbatches integrate colorants with additives in a single concentrate, streamlining production by reducing steps and equipment downtime while achieving vivid, durable hues.

Categorize:

XLPE XLPO TPU TPE PUR PVC Masterbatch for Wires

Keyword:

**FEP ETFE Color Masterbatch for Wires and Cables**

In the modern world, the demand for high-performance materials in various industries is on the rise. One such material that has gained significant attention is the FEP (Fluorinated Ethylene Propylene) ETFE (Ethylene Tetrafluoroethylene) color masterbatch. This specialized product has become a game-changer in the manufacturing of wires and cables, offering unique properties that enhance performance and durability. This article explores the benefits, applications, and considerations of using FEP ETFE color masterbatch in the wire and cable industry.

**Understanding FEP and ETFE**

Before delving into the specifics of FEP ETFE color masterbatch, it is essential to understand the components involved. FEP is a type of fluoropolymer known for its excellent chemical resistance, high-temperature stability, and low friction properties. ETFE, on the other hand, is another fluoropolymer that exhibits superior mechanical strength and resistance to UV radiation, making it an ideal choice for outdoor applications.

When combined, FEP and ETFE create a masterbatch that possesses the best characteristics of both materials. This masterbatch serves as a carrier for pigments and additives, allowing manufacturers to produce colored wires and cables without compromising on performance. The result is a product that is not only visually appealing but also highly functional.

**Benefits of FEP ETFE Color Masterbatch**

1. **Enhanced Durability**: One of the most significant advantages of using FEP ETFE color masterbatch is its exceptional durability. The materials are resistant to harsh environmental conditions, including extreme temperatures, moisture, and chemicals. This makes them ideal for applications in industries such as automotive, aerospace, and telecommunications, where reliability is paramount.

2. **Excellent Electrical Properties**: Wires and cables require materials with excellent electrical insulation properties. FEP and ETFE both exhibit low dielectric constants, ensuring that they can effectively insulate electrical components. This characteristic helps prevent energy loss and reduces the risk of short circuits, making them suitable for high-voltage applications.

3. **Color Customization**: The use of color masterbatch allows for a wide range of color options. This not only enhances the aesthetic appeal of wires and cables but also facilitates easier identification and organization in complex systems. Custom colors can be developed to meet specific customer requirements, ensuring that manufacturers can offer tailored solutions.

4. **Low Smoke and Toxicity**: In case of fire, the materials used in wires and cables can significantly impact safety. FEP ETFE color masterbatch is known for producing low smoke and low toxicity emissions when exposed to flames. This is crucial for applications in public spaces, such as buildings and transportation systems, where safety regulations are stringent.

**Applications of FEP ETFE Color Masterbatch**

The versatility of FEP ETFE color masterbatch allows it to be used in a variety of applications across different industries. Some notable applications include:

1. **Automotive Industry**: In the automotive sector, wires and cables must withstand extreme conditions, including high temperatures and exposure to chemicals. FEP ETFE color masterbatch is used in the production of wiring harnesses, connectors, and insulation materials, ensuring long-lasting performance.

2. **Telecommunications**: The telecommunications industry relies on high-quality cables for signal transmission. FEP ETFE color masterbatch is used in the production of fiber optic cables and other communication wires, providing the necessary insulation and protection against environmental factors.

3. **Aerospace**: In aerospace applications, weight and reliability are critical. FEP ETFE color masterbatch is utilized in wiring systems and components that require both lightweight materials and excellent performance under extreme conditions.

4. **Industrial Equipment**: Many industrial applications require robust wiring solutions. FEP ETFE color masterbatch is used in machinery, control systems, and equipment that operate in harsh environments, ensuring longevity and safety.

**Considerations When Using FEP ETFE Color Masterbatch**

While FEP ETFE color masterbatch offers numerous benefits, there are also considerations that manufacturers should keep in mind.

1. **Cost**: Fluoropolymers tend to be more expensive than traditional materials. Manufacturers need to evaluate the cost-benefit ratio when deciding to incorporate FEP ETFE color masterbatch into their production processes.

2. **Processing Conditions**: The processing of FEP and ETFE can require specialized equipment and techniques. It is essential for manufacturers to have the appropriate machinery and expertise to handle these materials effectively.

3. **Compatibility**: When selecting a color masterbatch, it is crucial to ensure compatibility with other materials used in the wire and cable production process. This includes considering the melting temperatures and processing methods to avoid any adverse reactions.

**Conclusion**

FEP ETFE color masterbatch is a remarkable innovation in the wire and cable industry, providing enhanced durability, excellent electrical properties, and customizable color options. Its applications span various sectors, including automotive, telecommunications, aerospace, and industrial equipment. While there are considerations to keep in mind, the benefits of using FEP ETFE color masterbatch far outweigh the challenges. As industries continue to evolve and demand higher performance materials, FEP ETFE color masterbatch is poised to play a vital role in shaping the future of wires and cables. Manufacturers who embrace this technology will not only enhance their product offerings but also ensure that they meet the stringent demands of modern applications.

Certification

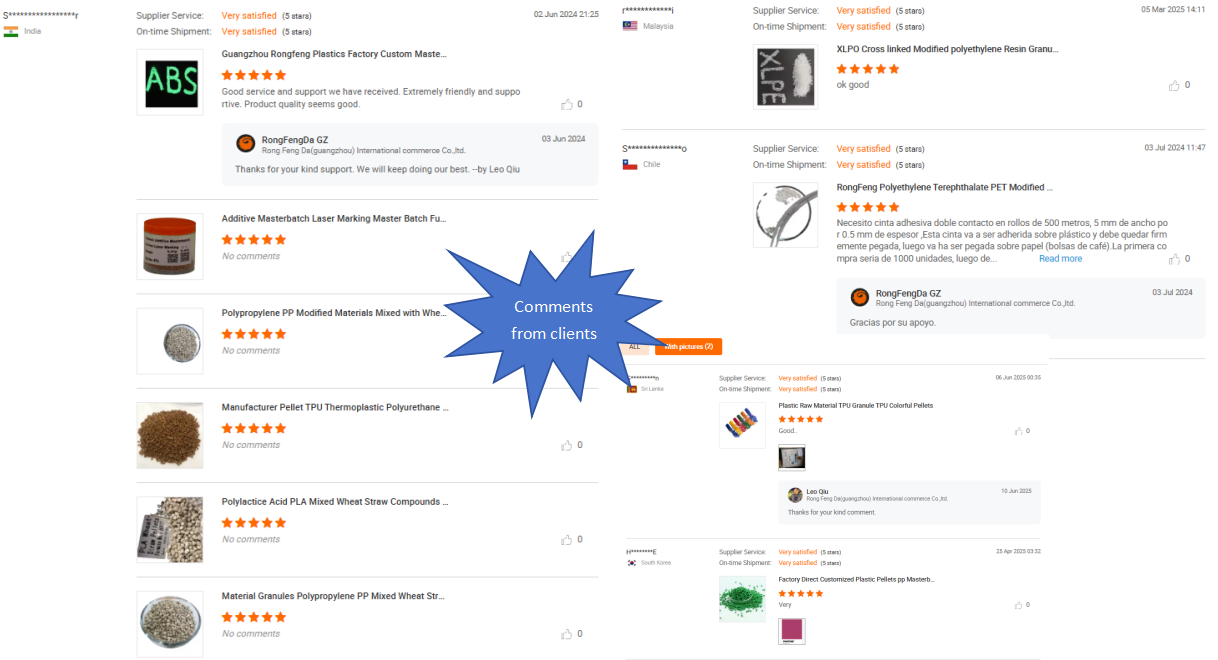

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.