PRODUCTS

Glow in Dark Additive Masterbatch

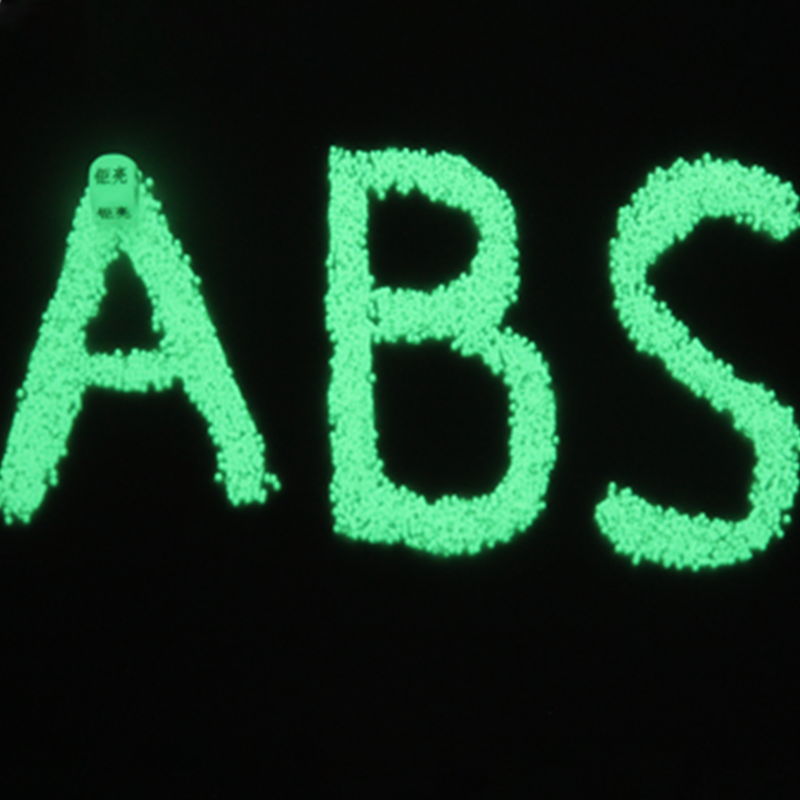

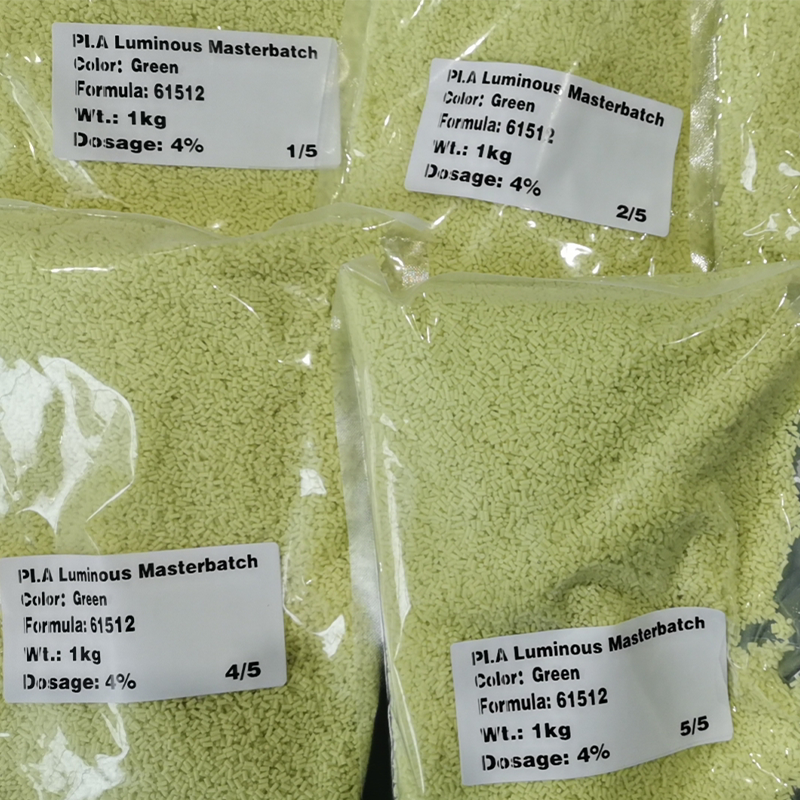

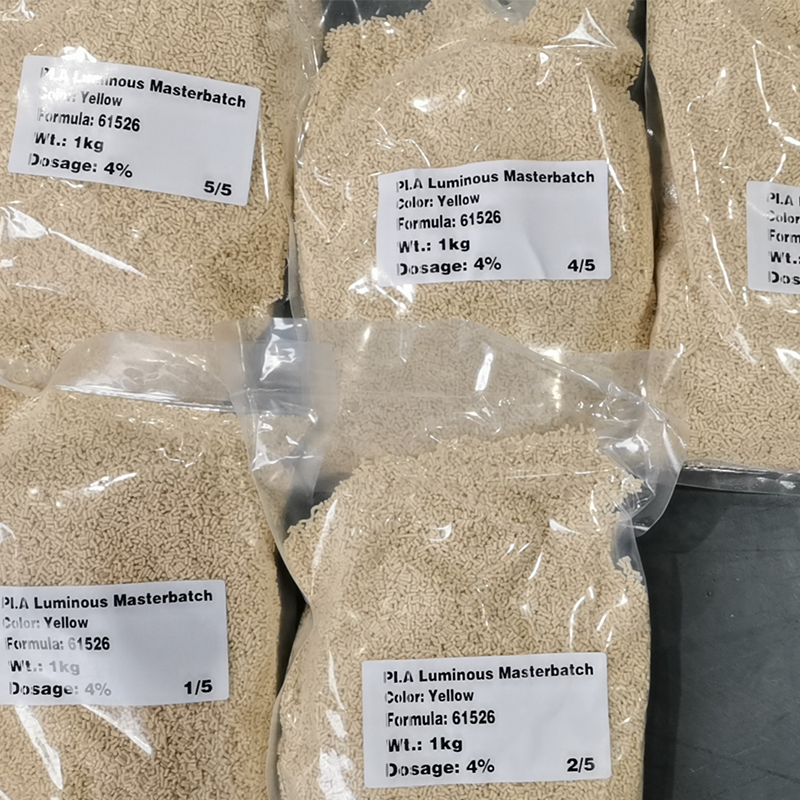

Glow in the dark masterbatch is a specialized additive used in plastic manufacturing to create luminescent products. It contains phosphorescent pigments, typically strontium aluminate, which absorb and store light energy, then emit a soft glow in darkness. This masterbatch is mixed with base polymers like PP, PE, PLA, PETG, or ABS during injection molding or extrusion. Key applications include safety signs, toys, watch dials, and decorative items. The glow duration and intensity depend on pigment concentration and light exposure time. It's non-toxic, durable, and rechargeable under UV or sunlight. Manufacturers value its ease of processing and consistent dispersion. This innovative material combines functionality with aesthetic appeal for nighttime visibility solutions.

Categorize:

Additive Masterbatch

Keyword:

Supporting Products

Glow-in-dark Additive Masterbatch

In the ever-evolving world of materials science and manufacturing, innovation continues to pave the way for exciting new products. One such innovation is the glow-in-the-dark additive masterbatch, a specialized type of plastic that incorporates luminescent properties. This article will explore what glow-in-the-dark additive masterbatch is, its applications, benefits, and the technology behind it.

**Understanding Glow-in-the-Dark Additive Masterbatch**

Glow-in-the-dark additive masterbatch is a concentrated mixture of plastic resins and luminescent pigments. These pigments are typically made from phosphorescent materials, which absorb light energy and re-emit it over a period of time. The masterbatch is designed to be blended with a polymer base during the manufacturing process, allowing for the creation of plastic products that can glow in the dark after being exposed to light.

The process of creating this masterbatch involves careful selection of materials to ensure that the glow-in-the-dark properties are maximized. Common luminescent materials include zinc sulfide and strontium aluminate, with the latter being more effective due to its longer afterglow duration and brighter luminescence.

**Applications of Glow-in-the-Dark Additive Masterbatch**

The applications of glow-in-the-dark additive masterbatch are vast and varied, spanning multiple industries. One of the most prominent uses is in consumer products, where it is incorporated into toys, safety gear, and decorative items. For instance, children's toys that glow in the dark can provide both entertainment and a sense of security for young children at night.

In the safety and emergency sectors, glow-in-the-dark masterbatch is used to create signage and markings that are visible in low-light conditions. This can include exit signs, emergency pathways, and safety equipment, which are crucial for ensuring safety during power outages or emergencies.

Another significant application is in the automotive industry, where glow-in-the-dark materials are used for vehicle interiors and exteriors. These materials can enhance visibility and provide an aesthetic appeal, making vehicles more attractive to consumers.

Additionally, the construction industry has begun to explore the use of glow-in-the-dark masterbatch for flooring, tiles, and other building materials. This not only adds an artistic touch but also improves safety in dark environments, such as staircases and hallways.

**Benefits of Using Glow-in-the-Dark Additive Masterbatch**

The benefits of incorporating glow-in-the-dark additive masterbatch into products are numerous. First and foremost, the safety aspect cannot be overstated. Products that glow in the dark can significantly enhance visibility in low-light conditions, helping to prevent accidents and injuries. This is particularly important in public spaces, where safety is a priority.

Moreover, glow-in-the-dark materials can add a unique aesthetic appeal to products. They can attract consumers looking for innovative and eye-catching designs. This can give companies a competitive edge in the market, as consumers are increasingly drawn to products that offer both functionality and visual appeal.

From a manufacturing perspective, using a masterbatch simplifies the production process. Manufacturers can easily incorporate the glow-in-the-dark additive into their existing production lines without requiring significant changes to their equipment. This can lead to cost savings and increased efficiency.

Furthermore, glow-in-the-dark materials are generally durable and can withstand environmental factors such as moisture and UV exposure. This makes them suitable for both indoor and outdoor applications, ensuring that the products maintain their luminescent properties over time.

**The Technology Behind Glow-in-the-Dark Additive Masterbatch**

The technology behind glow-in-the-dark additive masterbatch is rooted in the principles of photoluminescence. When the luminescent pigments are exposed to light, they absorb energy and enter an excited state. As they return to their ground state, they release the absorbed energy in the form of visible light, creating the glow effect.

The efficiency of this process depends on several factors, including the type of pigment used, the duration of light exposure, and the environmental conditions. Strontium aluminate, for example, is known for its high brightness and long afterglow time, making it a popular choice for manufacturers.

Additionally, advancements in nanotechnology have enabled the development of even more effective luminescent materials. Researchers are continually exploring new formulations and methods to enhance the performance of glow-in-the-dark additives, leading to brighter, longer-lasting products.

**Conclusion**

In conclusion, glow-in-the-dark additive masterbatch represents a fascinating intersection of creativity and technology in the world of materials science. Its versatility and safety benefits make it an attractive option for a wide range of applications, from consumer products to industrial uses. As manufacturers continue to innovate and explore new possibilities, we can expect to see even more exciting developments in the realm of glow-in-the-dark materials. With their unique properties and aesthetic appeal, glow-in-the-dark additive masterbatches are set to illuminate our lives in more ways than one.

Next

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.