PRODUCTS

Light Diffusion Additive

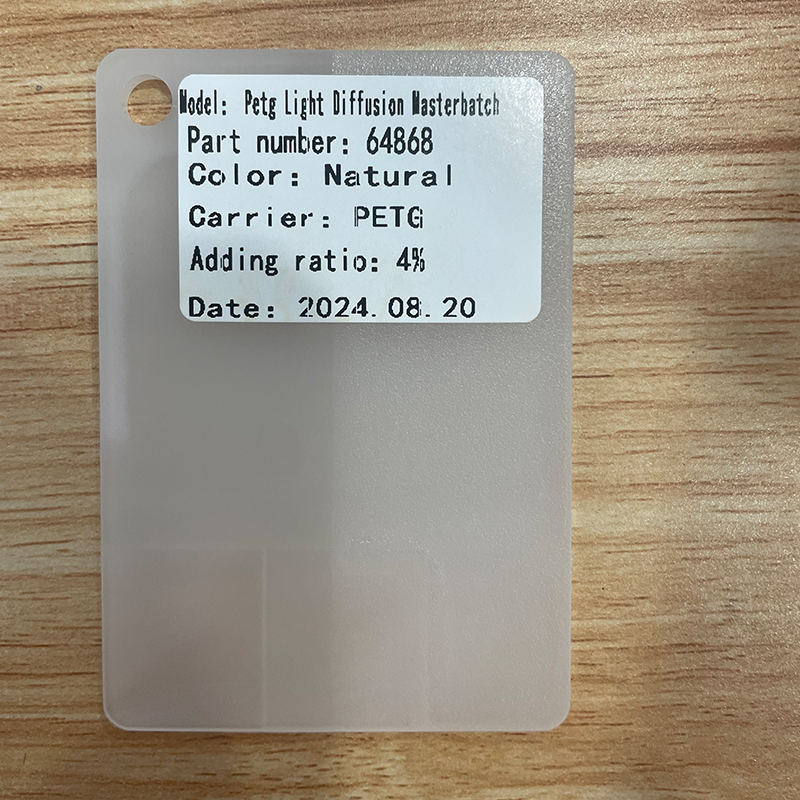

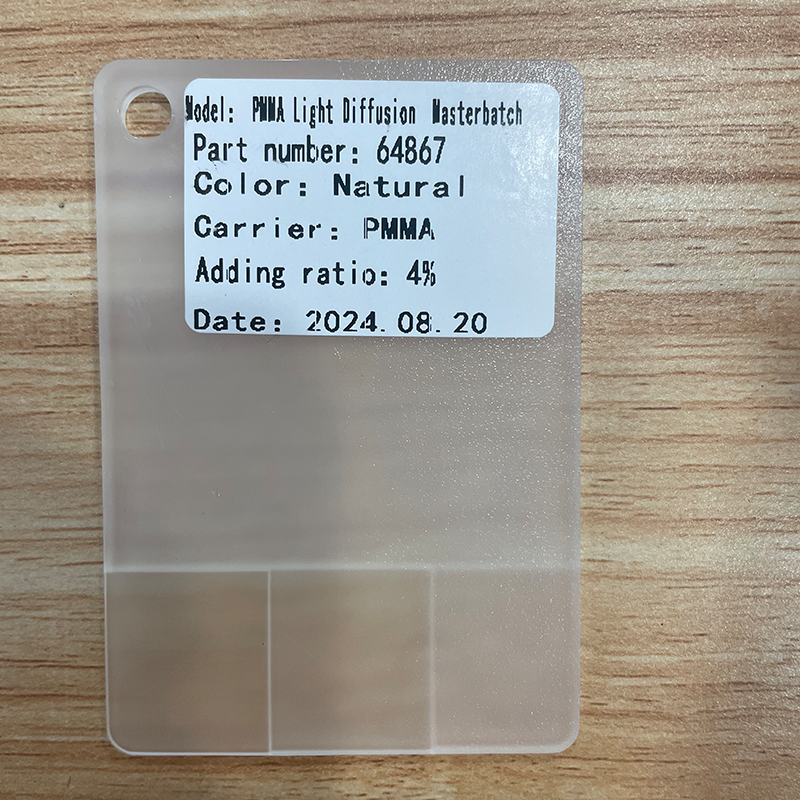

Light Diffusion Additive Masterbatch Concentrated polymer carriers (PC, PMMA, PS) infused with 5–25% micron-scale light-scattering particles (e.g., silica, acrylic, or silicone spheres). Engineered to uniformly diffuse LED/display light while maintaining high transmission (>85%)14. Technical Function Controlled Haze: Adjustable diffusion (10–95% haze) via particle size (2–20μm) and loading. Minimal Absorption: Optimized refractive index mismatch maximizes brightness with <3% luminance loss. Critical Advantages Thermal Stability: Withstands 240–300°C processing (injection molding, extrusion). Mechanical Integrity: Preserves base resin strength (impact resistance ±8%). Surface Quality: Prevents speckling/defects; non-migrating formulation. Applications & Performance LED Lighting: Covers, lenses, panels (eliminates hotspots; Glow Uniformity >92%). Electronics: LCD backlight units, touchscreens, automotive displays. Dosage: 1–7% (films), 3–10% (thick sections).

Categorize:

Additive Masterbatch

Keyword:

Supporting Products

Title: Light Diffusion Additive

In the realm of modern manufacturing and material science, the quest for improved optical properties has led to the development of various additives designed to enhance light diffusion in different materials. Among these, light diffusion additives play a crucial role in applications ranging from consumer electronics to automotive lighting and architectural designs. This article delves into the significance, functionality, and applications of light diffusion additives, exploring how they transform materials to meet the demands of contemporary technology.

Light diffusion refers to the scattering of light as it passes through a material, which can significantly influence the aesthetic and functional characteristics of products. A well-diffused light source provides uniform illumination, reducing glare and enhancing visibility. This is particularly important in applications such as backlit displays, where the even distribution of light enhances user experience. Light diffusion additives are specifically formulated compounds added to polymers, resins, or coatings to achieve desired diffusion properties.

One of the primary functions of light diffusion additives is to alter the refractive index of a material, which impacts how light interacts with it. By incorporating these additives, manufacturers can create materials that scatter light effectively, providing a softer glow without sacrificing brightness. This is particularly advantageous in LED lighting applications, where harsh direct light can be uncomfortable for users. The right additive can transform a rigid, transparent plastic into a material that emits a warm, inviting light.

The choice of light diffusion additive depends on various factors, including the base material, the desired level of diffusion, and the specific application. Common types of additives include microspheres, polymeric compounds, and nanomaterials. Microspheres, often made from glass or polymer, can be added to plastics to create a frosted effect, enhancing light diffusion. Polymeric compounds can be engineered to provide specific scattering properties, while nanomaterials offer advanced capabilities, such as enhanced thermal stability and mechanical strength.

In the automotive industry, light diffusion additives are increasingly used in headlight and taillight applications. The automotive sector demands not only functional lighting but also design aesthetics. By using diffusion additives, manufacturers can create lights that appear sleek and modern while providing optimal visibility for drivers. The integration of these additives allows for creative designs that do not compromise on safety or performance.

Architectural lighting is another area where light diffusion additives have made a significant impact. In commercial and residential buildings, the quality of light can influence mood, productivity, and overall ambiance. By using materials infused with light diffusion additives, architects and designers can achieve soft, even lighting that enhances the aesthetic appeal of spaces. These materials can be used in light fixtures, wall panels, and ceilings, contributing to energy-efficient designs that reduce reliance on artificial lighting.

The environmental impact of materials is a growing concern in today's world. Light diffusion additives can contribute to sustainability efforts by enabling the use of lower-energy light sources. By improving the efficiency of light output, these additives can help reduce energy consumption in lighting applications. Additionally, many manufacturers are now focusing on developing eco-friendly additives derived from renewable resources, aligning with the global push towards sustainable practices.

As technology continues to evolve, the demand for innovative lighting solutions grows. Light diffusion additives are at the forefront of this evolution, offering new possibilities for product design and functionality. With advancements in material science, researchers are exploring new types of additives that can provide even greater levels of light diffusion while minimizing environmental impact. The future holds exciting potential for these additives, particularly in the realm of smart lighting systems that adapt to user preferences and environmental conditions.

In conclusion, light diffusion additives play an essential role in enhancing the optical properties of various materials, transforming the way light is utilized in numerous applications. From automotive lighting to architectural design, these additives provide solutions that improve visibility, aesthetics, and energy efficiency. As the industry continues to innovate, the importance of light diffusion additives will only grow, paving the way for a brighter and more sustainable future in lighting technology. By understanding and harnessing the power of these additives, manufacturers can create products that not only meet the demands of consumers but also contribute to a more sustainable world.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.