PRODUCTS

PP Chameleon Effect Masterbatch

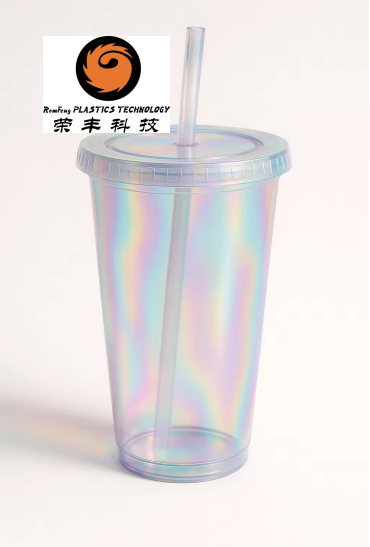

PP Chameleon Effect Masterbatch is a specialized additive for polypropylene (PP) processing, engineered to deliver dynamic color-shifting properties. Infused with advanced interference pigments (e.g., mica-based or coated flakes), it creates an iridescent "chameleon" effect where hues transition seamlessly based on viewing angle and lighting. Ideal for injection molding, blow molding, or extrusion, it enhances products like packaging, automotive trims, cosmetics containers, and consumer electronics with mesmerizing, high-end aesthetics. The masterbatch simplifies production—pre-dispersed pigments in a PP carrier ensure uniform blending, optimal pigment dispersion, and compatibility with existing processing equipment. Requires no special handling, offering cost-efficient, vibrant visual appeal that captivates end-users and boosts brand differentiation.

Categorize:

PP Mastebatch

Keyword:

PP Chameleon Effect Masterbatch

In recent years, the demand for innovative and aesthetically appealing materials has surged in various industries, particularly in plastics and packaging. One of the most intriguing developments in this area is the introduction of PP Chameleon Effect Masterbatch. This specialized additive offers a unique visual experience by altering the color of polypropylene (PP) products depending on the angle of light and viewing perspective. This article explores the characteristics, applications, advantages, and future prospects of PP Chameleon Effect Masterbatch.

Understanding PP Chameleon Effect Masterbatch

At its core, PP Chameleon Effect Masterbatch is a concentrated mixture of pigments and additives designed to impart a color-changing effect to polypropylene products. The term "chameleon effect" refers to the ability of the material to display different colors when viewed from different angles. This phenomenon is achieved through the use of special interference pigments or color-shifting dyes that react to light in unique ways. When incorporated into PP, these masterbatches can create stunning visual effects that enhance the aesthetic appeal of the final product.

The production of PP Chameleon Effect Masterbatch involves a careful selection of raw materials and precise manufacturing processes. High-quality pigments are essential for achieving the desired color effects, while the masterbatch must be compatible with polypropylene to ensure uniform dispersion and optimal performance. Manufacturers often conduct extensive testing to ensure that the masterbatch meets industry standards for quality, stability, and safety.

Applications of PP Chameleon Effect Masterbatch

The versatility of PP Chameleon Effect Masterbatch allows it to be used in a wide range of applications across various industries. One of the most prominent sectors utilizing this technology is the packaging industry. Packaging plays a crucial role in attracting consumers, and products that exhibit unique color-changing effects are more likely to stand out on the shelves. From food packaging to cosmetic containers, the chameleon effect adds an element of intrigue and luxury, enhancing brand appeal.

In addition to packaging, PP Chameleon Effect Masterbatch is also making its mark in the automotive industry. Car manufacturers are increasingly looking for innovative ways to differentiate their vehicles, and the chameleon effect provides an exciting option. By incorporating these masterbatches into exterior components such as trims, panels, and bumpers, manufacturers can offer consumers a unique visual experience that sets their vehicles apart from the competition.

Another notable application is in consumer goods, including electronic devices, toys, and home décor. Products with a chameleon effect can capture the attention of consumers, creating a sense of novelty and excitement. This has led to an increased demand for PP Chameleon Effect Masterbatch in the production of items like smartphone cases, decorative items, and novelty gifts.

Advantages of Using PP Chameleon Effect Masterbatch

The use of PP Chameleon Effect Masterbatch offers several advantages that make it an attractive option for manufacturers and consumers alike. Firstly, the aesthetic appeal of products featuring the chameleon effect can significantly enhance their marketability. In a crowded marketplace, products that stand out visually can capture consumer interest and drive sales.

Secondly, the chameleon effect can provide a sense of luxury and exclusivity. As consumers increasingly seek unique and high-quality products, incorporating color-changing features can elevate the perceived value of items. This is particularly important in industries such as cosmetics and luxury packaging, where presentation is key.

Furthermore, PP Chameleon Effect Masterbatch can contribute to product differentiation. Manufacturers can create unique color combinations and effects that are not easily replicated by competitors. This can foster brand loyalty and encourage repeat purchases as consumers associate specific colors or effects with a particular brand.

Additionally, the use of PP Chameleon Effect Masterbatch can improve the overall performance of polypropylene products. Many masterbatches are designed to enhance properties such as UV resistance, heat stability, and mechanical strength. This means that manufacturers can achieve both aesthetic and functional benefits when using these additives.

Future Prospects of PP Chameleon Effect Masterbatch

As technology continues to evolve, the future of PP Chameleon Effect Masterbatch looks promising. Ongoing research and development efforts are focused on enhancing the color-shifting capabilities and expanding the range of available colors and effects. This could lead to even more creative applications and innovations in various industries.

Moreover, the growing emphasis on sustainability in the plastics industry is likely to influence the development of eco-friendly chameleon effect masterbatches. Manufacturers are increasingly seeking to produce materials that are not only visually appealing but also environmentally responsible. This could involve the use of biodegradable or recycled materials in the production of masterbatches.

In conclusion, PP Chameleon Effect Masterbatch represents an exciting advancement in the field of plastics and packaging. Its unique ability to change colors based on viewing angles offers manufacturers a powerful tool for enhancing product aesthetics and differentiation. As industries continue to evolve, the applications and benefits of this innovative material are likely to expand, paving the way for new possibilities in design and functionality. The chameleon effect is not just a passing trend; it is a glimpse into the future of product innovation and consumer engagement.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.