PRODUCTS

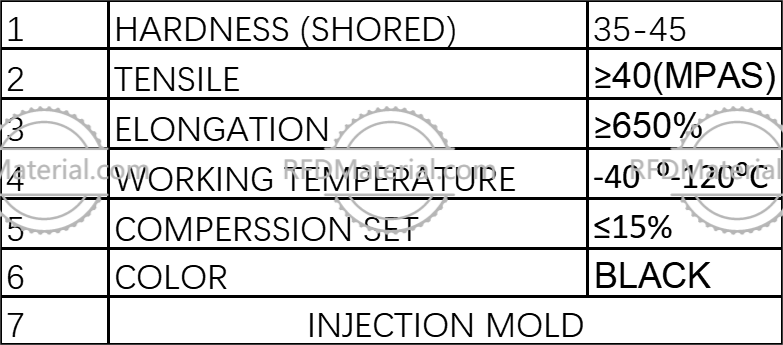

120 ℃ -40 ℃ Hardness Shore D 45 TPE Car Dust Covers Special Elastic Material

Special Elastic TPE for Auto Dust Covers -40°C~120°C Shore D45 Industrial Grade

Categorize:

Product

Modified Materials For Wires And Cables

Keyword:

**120 ℃ -40 ℃ Hardness Shore D 45 TPE Car Dust Covers Special Elastic Material**

In the automotive industry, the materials used for various components play a crucial role in determining the performance, durability, and reliability of vehicles. One such material that has gained popularity in recent years is Thermoplastic Elastomer (TPE). Among the different grades of TPE, those with a hardness of Shore D 45 and a temperature range of 120 ℃ to -40 ℃ are particularly noteworthy for applications such as car dust covers. This article will delve into the properties, advantages, and applications of this special elastic material.

**Understanding TPE and Its Properties**

Thermoplastic Elastomers are a class of polymers that combine the characteristics of rubber with the processing advantages of thermoplastics. TPEs are widely used in various applications due to their unique properties, including elasticity, flexibility, and resilience. The hardness measurement of Shore D 45 indicates a material that is firm yet flexible, making it ideal for applications where a balance between rigidity and elasticity is required.

The temperature resistance of TPE, particularly in the range of 120 ℃ to -40 ℃, allows it to maintain its performance under extreme conditions. This broad temperature range is essential for automotive applications, where components can be exposed to high temperatures from engine heat and low temperatures in cold weather conditions. The ability to withstand such extremes without losing functionality is one of the primary reasons TPE is chosen for car dust covers.

**Advantages of Using TPE for Car Dust Covers**

1. **Durability and Longevity**: TPE materials are known for their exceptional durability. They resist wear and tear, UV radiation, and environmental factors that can degrade other materials. This durability translates to a longer lifespan for car dust covers, reducing the need for frequent replacements.

2. **Elasticity and Flexibility**: The Shore D 45 hardness provides an excellent balance of rigidity and flexibility. This allows car dust covers to fit snugly while still being easy to install and remove. The elasticity of TPE ensures that the covers can stretch and adapt to different shapes and sizes, providing a custom fit for various vehicle models.

3. **Chemical Resistance**: TPE is inherently resistant to a wide range of chemicals, including oils, fuels, and cleaning agents commonly found in automotive environments. This resistance helps to maintain the integrity of the dust covers, preventing degradation and ensuring they perform effectively over time.

4. **Environmentally Friendly**: Many TPE formulations are recyclable, making them an environmentally friendly choice compared to traditional rubber or plastic materials. The use of sustainable materials in automotive manufacturing is becoming increasingly important, and TPE aligns well with these goals.

5. **Cost-Effectiveness**: While the initial cost of TPE materials may be higher than some alternatives, the long-term savings associated with durability and reduced maintenance make it a cost-effective option for car dust covers. The efficiency of TPE in manufacturing processes also contributes to overall cost savings.

**Applications of TPE Car Dust Covers**

Car dust covers made from TPE are versatile and can be used in various automotive applications. Some common uses include:

1. **Protective Covers for Engine Components**: TPE dust covers are often used to protect sensitive engine components from dust, debris, and moisture. By preventing contaminants from entering critical areas, these covers help maintain optimal performance and extend the lifespan of engine parts.

2. **Sealing Applications**: TPE is frequently used in sealing applications within vehicles, such as around doors, windows, and trunk lids. The elasticity of TPE allows it to create effective seals that prevent water and air leaks, contributing to improved vehicle efficiency and comfort.

3. **Covers for Electrical Connections**: Electrical connections in vehicles are vulnerable to moisture and dirt, which can lead to corrosion and electrical failures. TPE dust covers provide a reliable barrier against these elements, ensuring the longevity and reliability of electrical systems.

4. **Custom Applications**: The versatility of TPE allows manufacturers to create custom dust covers tailored to specific components or vehicle models. This customization ensures a perfect fit and optimal protection for various automotive applications.

**Conclusion**

In summary, the use of TPE with a hardness of Shore D 45 and a temperature range of 120 ℃ to -40 ℃ for car dust covers represents a significant advancement in automotive materials. Its durability, flexibility, chemical resistance, and environmental benefits make it an ideal choice for protecting vehicle components under a wide range of conditions. As the automotive industry continues to evolve, the adoption of innovative materials like TPE will play a crucial role in enhancing vehicle performance and sustainability. By investing in high-quality TPE car dust covers, manufacturers can ensure that their vehicles remain protected, efficient, and reliable for years to come.

Pre

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.