PRODUCTS

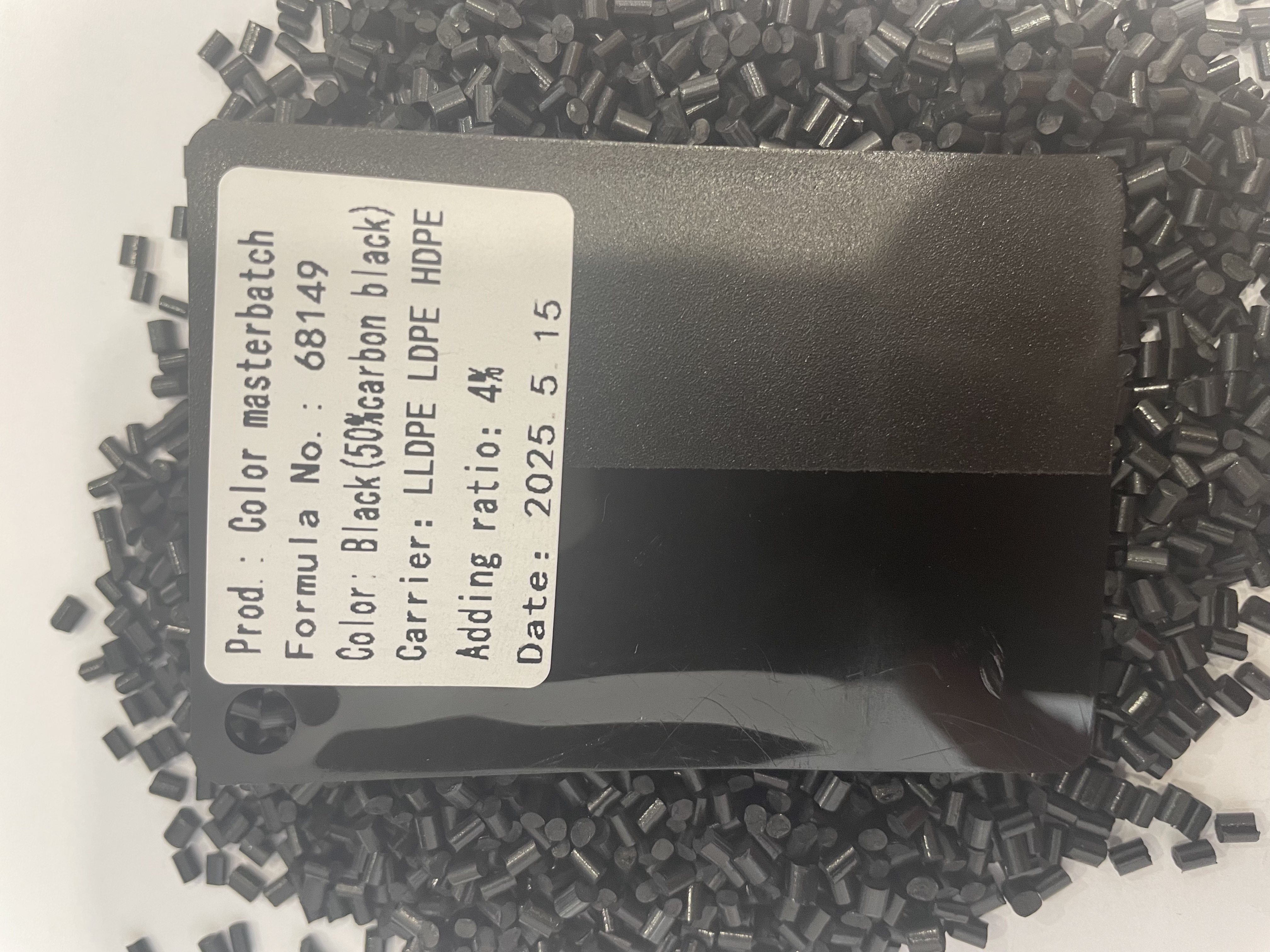

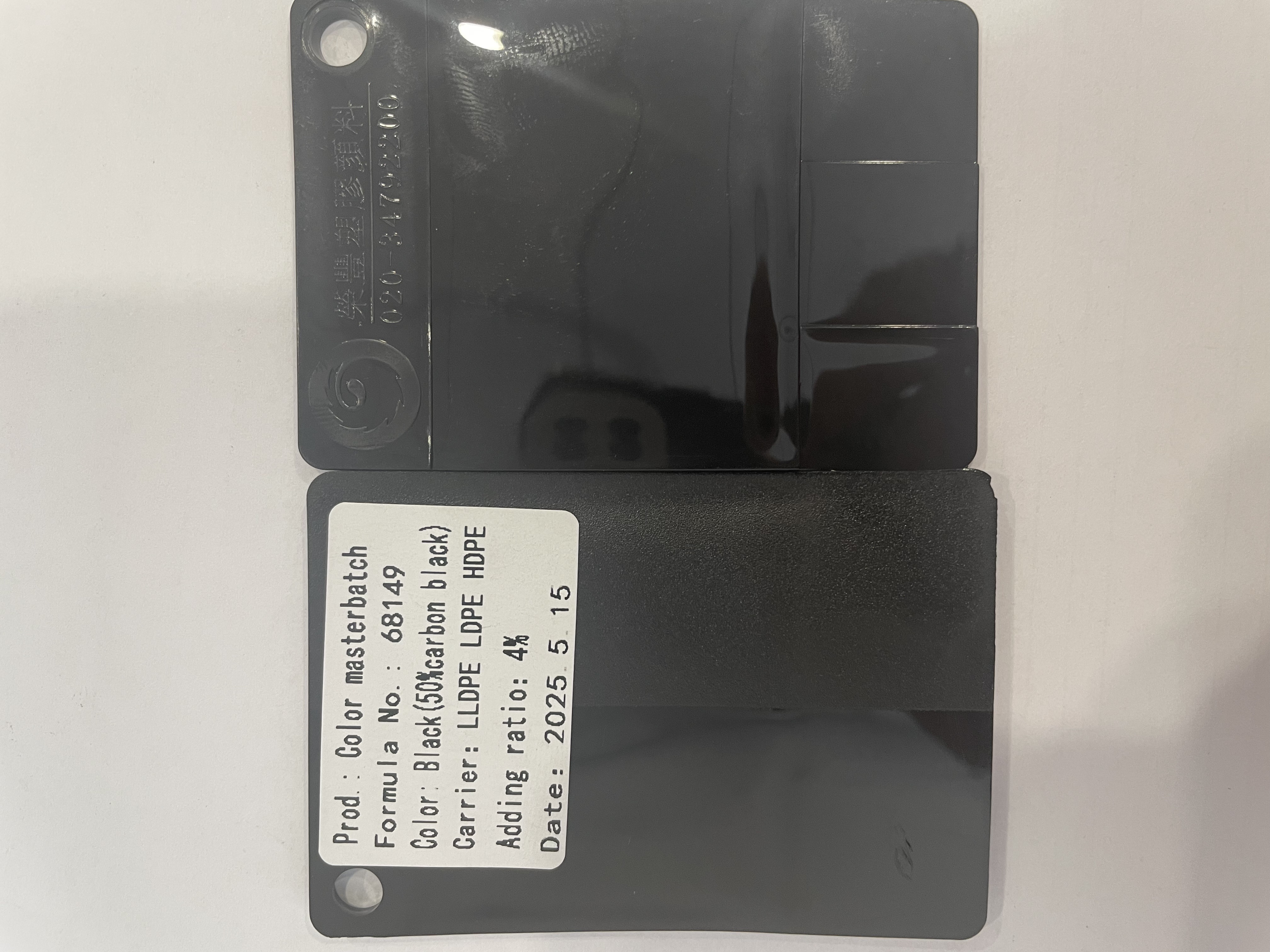

Black Masterbatch for LDPE HDPE LDPE

PE black masterbatch is a concentrated pigment additive for polyethylene (PE) products, composed of high-grade carbon black (50-70% content) dispersed in a PE carrier. It ensures uniform black coloration with excellent UV resistance and thermal stability (up to 180°C for PE applications). Widely used in pipes, films, and packaging, it offers advantages like: High opacity for superior coverage of recycled materials Eco-friendly options compliant with ROHS standards Low dosage (1-3% recommended) to maintain PE’s mechanical properties. Available in customized formulations for blow molding, extrusion, or injection processes, it enhances product durability and aesthetics.

Categorize:

PE Masterbatch

Keyword:

Title: Black Masterbatch for LDPE and HDPE

Introduction

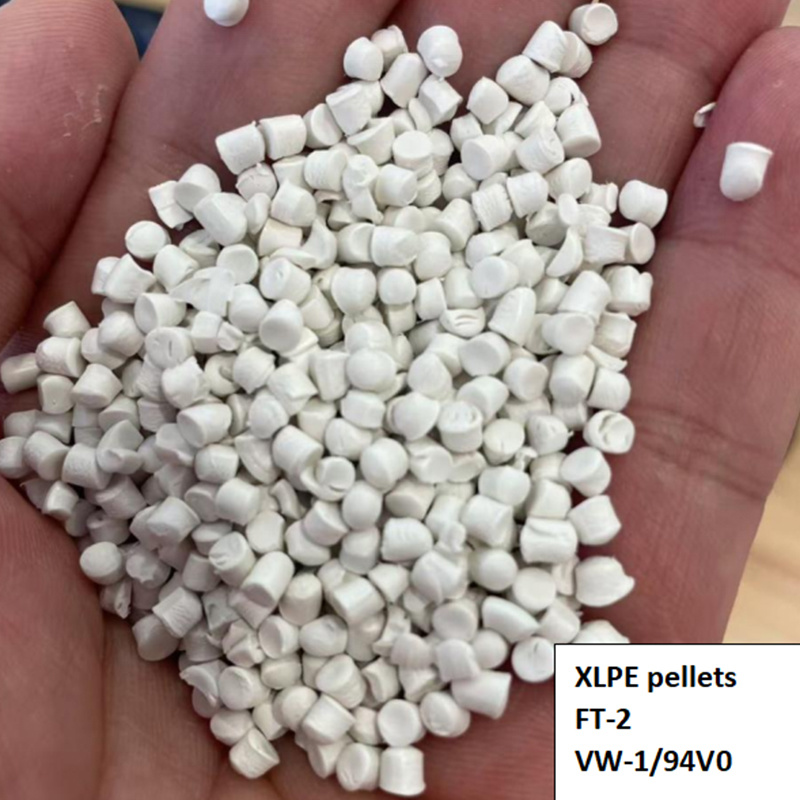

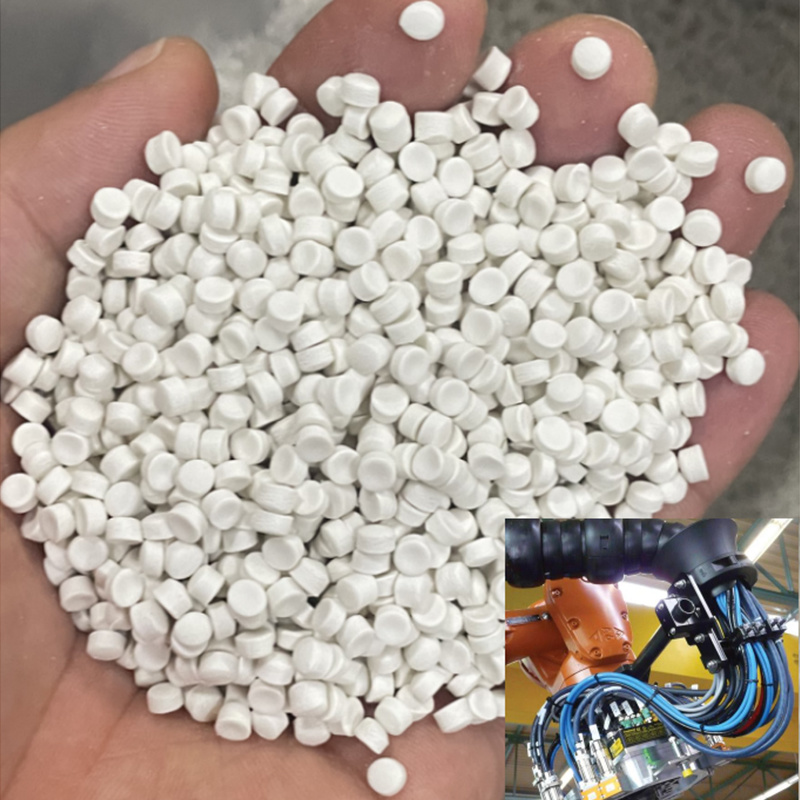

In the realm of plastic manufacturing, the use of masterbatches has become a pivotal aspect in enhancing the performance and aesthetic appeal of polymer products. Among various types of masterbatches, black masterbatch stands out as a popular choice, particularly for Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE). This article delves into the characteristics, applications, and benefits of black masterbatch in LDPE and HDPE, shedding light on its significance in the plastics industry.

What is Black Masterbatch?

Black masterbatch is a concentrated mixture of pigments, additives, and a polymer carrier, typically polyethylene, that is used to impart black color to plastic products. It is produced by dispersing carbon black or other black pigments in a polymer matrix, which is then pelletized for easy handling and processing. The primary purpose of using black masterbatch is to achieve a uniform color and enhance the physical properties of the base polymer.

Characteristics of Black Masterbatch

The effectiveness of black masterbatch is attributed to several key characteristics. Firstly, the high pigment concentration allows for excellent color strength, ensuring that even a small amount of masterbatch can produce a deep black hue in the final product. Secondly, black masterbatch provides UV protection, which is crucial for outdoor applications, as it helps to prevent degradation caused by ultraviolet radiation.

Moreover, black masterbatch improves the mechanical properties of LDPE and HDPE, enhancing their tensile strength, impact resistance, and overall durability. The incorporation of carbon black not only adds color but also contributes to thermal stability, making these polymers more resilient under varying temperature conditions.

Applications of Black Masterbatch in LDPE and HDPE

Black masterbatch finds extensive applications in various sectors due to its versatility. In the packaging industry, LDPE and HDPE are widely used for producing bags, films, and containers. The use of black masterbatch in these applications not only provides an attractive appearance but also improves the barrier properties of the materials, protecting the contents from light and moisture.

In the automotive industry, black masterbatch is utilized in the manufacturing of interior and exterior components. The black color is often preferred for aesthetic reasons, while the enhanced mechanical properties ensure that the parts can withstand the rigors of daily use. Additionally, black masterbatch is used in the production of agricultural films, where its UV protection helps to extend the lifespan of the materials used in farming applications.

Benefits of Using Black Masterbatch

The incorporation of black masterbatch into LDPE and HDPE offers numerous benefits to manufacturers and end-users alike. One of the primary advantages is cost efficiency. By using masterbatch, manufacturers can achieve the desired color and properties without the need for extensive processing or additional additives. This not only reduces production costs but also simplifies the manufacturing process.

Furthermore, black masterbatch contributes to environmental sustainability. Many manufacturers are now focusing on eco-friendly practices, and the use of masterbatches allows for better recyclability of plastics. The carbon black used in black masterbatch can improve the recycling process, as it helps to stabilize the polymer and maintain its quality during recycling.

Moreover, the ease of handling and processing black masterbatch makes it an attractive option for manufacturers. The uniformity of the pellets ensures consistent color and performance in the final products, reducing the risk of defects and enhancing overall product quality.

Challenges and Considerations

While the benefits of black masterbatch are significant, there are also challenges and considerations that manufacturers must be aware of. One of the primary concerns is the potential environmental impact of carbon black. As regulations regarding carbon emissions become stricter, manufacturers may need to explore alternative pigments or more sustainable production methods.

Additionally, the selection of the right type of black masterbatch is crucial. Different grades of masterbatch may have varying levels of pigment concentration, dispersion quality, and compatibility with LDPE and HDPE. It is essential for manufacturers to conduct thorough testing to ensure that the chosen masterbatch meets their specific requirements and enhances the properties of the final product.

Conclusion

In conclusion, black masterbatch plays a vital role in enhancing the performance and aesthetic appeal of LDPE and HDPE products. Its unique characteristics, wide range of applications, and numerous benefits make it a preferred choice for manufacturers across various industries. As the demand for sustainable and high-quality plastic products continues to grow, the importance of black masterbatch in the plastics industry will only increase. By understanding its properties and applications, manufacturers can make informed decisions that will ultimately lead to improved product quality and greater customer satisfaction.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.