PRODUCTS

PE Color Masterbatch HDPE LDPE LLDPE

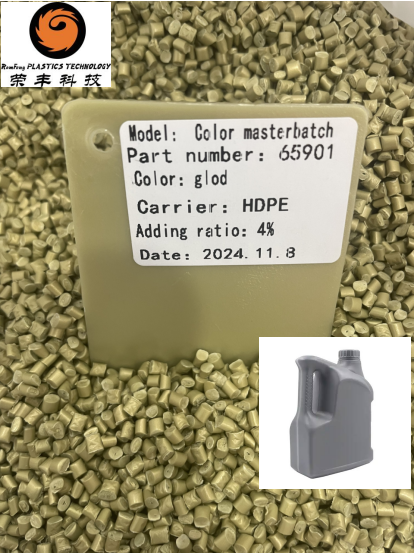

PE Color Masterbatch is a concentrated mixture of pigments and additives encapsulated in a polyethylene (PE) resin carrier. It is widely used in plastic products to provide uniform coloration during manufacturing processes like injection molding and extrusion. The masterbatch ensures excellent dispersion and color consistency while improving production efficiency and reducing costs compared to raw pigments. PE masterbatch comes in various colors and can be customized for specific applications in packaging, automotive parts, and consumer goods. Its key advantages include ease of processing, environmental friendliness, and stable thermal properties.

Categorize:

PE Masterbatch

Keyword:

**PE Color Masterbatch HDPE LDPE LLDPE**

Polyethylene (PE) is one of the most widely used plastics in the world, known for its versatility and excellent properties. It is categorized into different types, including High-Density Polyethylene (HDPE), Low-Density Polyethylene (LDPE), and Linear Low-Density Polyethylene (LLDPE). Each of these variations has unique characteristics that make them suitable for various applications. One of the most significant advancements in the use of PE is the development of color masterbatch, which enhances the aesthetic appeal and functionality of polyethylene products.

Color masterbatch is a concentrated mixture of pigments and/or additives encapsulated in a carrier resin, which is then used to color plastic products. This technology allows manufacturers to produce colored polyethylene items with consistent quality and reduced production costs. In this article, we will explore the different types of PE color masterbatch, focusing on HDPE, LDPE, and LLDPE, and their applications in various industries.

**Understanding the Types of Polyethylene**

To appreciate the significance of PE color masterbatch, it is essential to understand the different types of polyethylene.

1. **High-Density Polyethylene (HDPE)**: HDPE is known for its high strength-to-density ratio. It is widely used in applications that require durability and resistance to impact, such as containers, pipes, and industrial packaging. HDPE is also known for its excellent chemical resistance and is often used in environments where exposure to harsh substances is common.

2. **Low-Density Polyethylene (LDPE)**: LDPE is characterized by its low density and high flexibility. It is commonly used in applications such as plastic bags, films, and squeeze bottles. LDPE's ability to stretch and bend without breaking makes it an ideal choice for products that require a softer touch.

3. **Linear Low-Density Polyethylene (LLDPE)**: LLDPE combines the properties of both HDPE and LDPE. It offers higher tensile strength and greater elasticity than LDPE, making it suitable for applications that require both flexibility and strength. LLDPE is often used in stretch films, agricultural films, and various packaging solutions.

**The Role of Color Masterbatch in Polyethylene**

Color masterbatch plays a crucial role in enhancing the visual appeal and functionality of polyethylene products. By incorporating color masterbatch into the production process, manufacturers can achieve vibrant colors, consistent shades, and improved product differentiation.

One of the primary advantages of using color masterbatch is the ease of processing. Unlike traditional methods of coloring plastic, which often involve adding powders or liquids that can be difficult to mix uniformly, color masterbatch provides a pre-dispersed solution that ensures consistent coloration throughout the product. This consistency is essential for maintaining product quality and meeting customer expectations.

Additionally, color masterbatch can include various additives that enhance the properties of polyethylene. For instance, UV stabilizers can be added to protect products from degradation due to sunlight exposure, while antioxidants can help prolong the life of the plastic. This versatility allows manufacturers to create products that are not only visually appealing but also functional and durable.

**Applications of PE Color Masterbatch**

The applications of PE color masterbatch are vast and varied, spanning numerous industries.

1. **Packaging Industry**: In the packaging sector, color masterbatch is extensively used to produce eye-catching containers, bottles, and films. The ability to create custom colors allows brands to differentiate their products on the shelves, attracting consumers' attention. Moreover, the use of color masterbatch in food packaging can enhance product visibility while ensuring compliance with safety regulations.

2. **Agricultural Sector**: In agriculture, colored films made from LLDPE and LDPE are used for greenhouse covers and mulch films. The use of color masterbatch can help regulate temperature and light penetration, promoting optimal growth conditions for crops. For example, black mulch films can suppress weed growth, while white films can reflect sunlight to keep soil temperatures cooler.

3. **Consumer Goods**: Many everyday products, such as toys, household items, and furniture, utilize PE color masterbatch. The ability to create vibrant colors and unique designs enhances the appeal of these products, making them more attractive to consumers.

4. **Industrial Applications**: In the industrial sector, color masterbatch is used for safety equipment, warning signs, and color-coded containers. The use of bright colors helps improve visibility and communication, ensuring a safer working environment.

**Conclusion**

In conclusion, PE color masterbatch is a vital component in the production of HDPE, LDPE, and LLDPE products. Its ability to enhance the visual appeal and functionality of polyethylene items has made it an essential tool for manufacturers across various industries. As the demand for customized and aesthetically pleasing products continues to grow, the role of color masterbatch will only become more significant. By understanding the unique properties of different types of polyethylene and the advantages of color masterbatch, manufacturers can innovate and create products that meet the evolving needs of consumers and industries alike. The future of polyethylene products looks promising, driven by advancements in color masterbatch technology and the endless possibilities it offers.

Next

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.