PRODUCTS

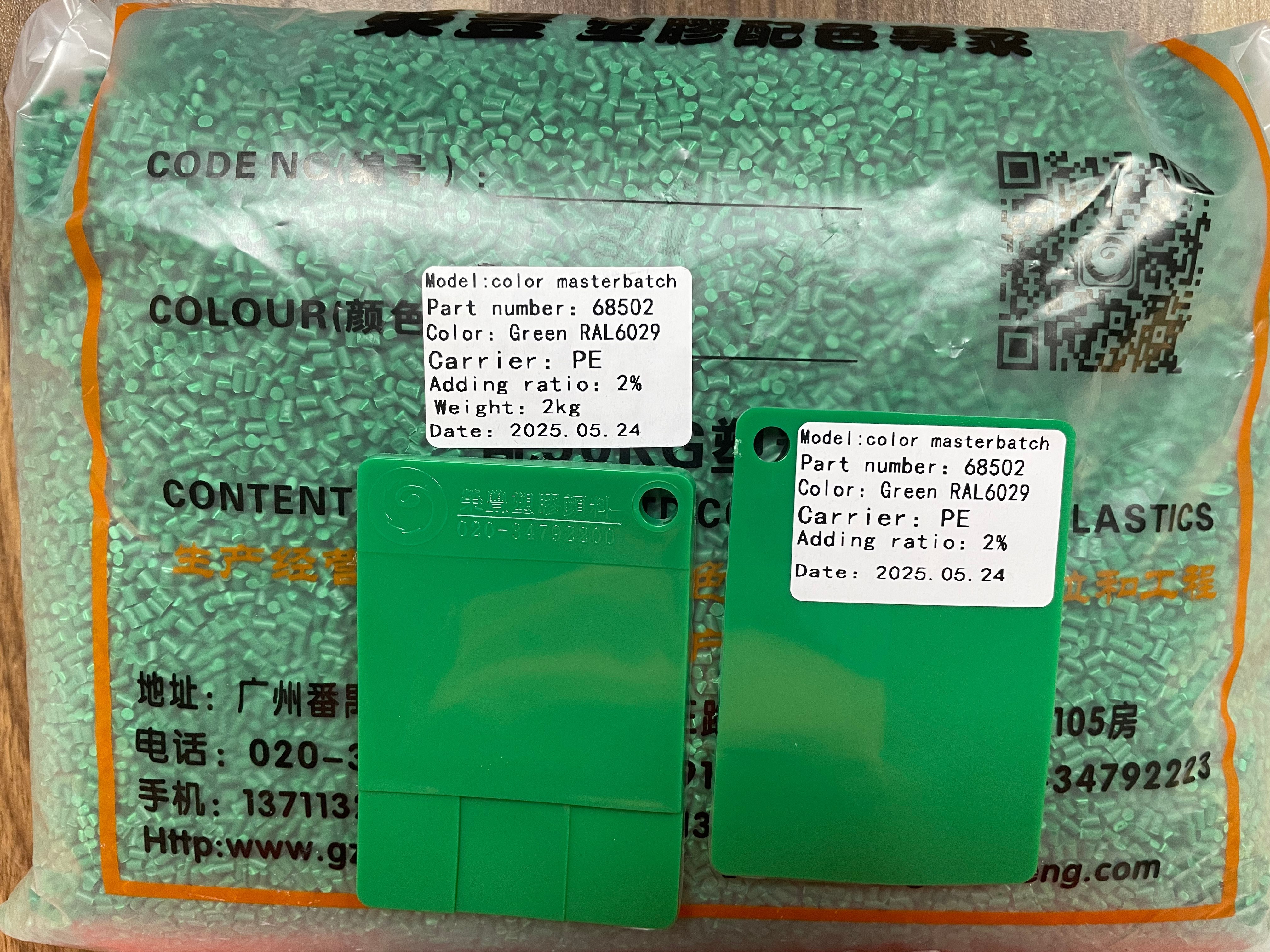

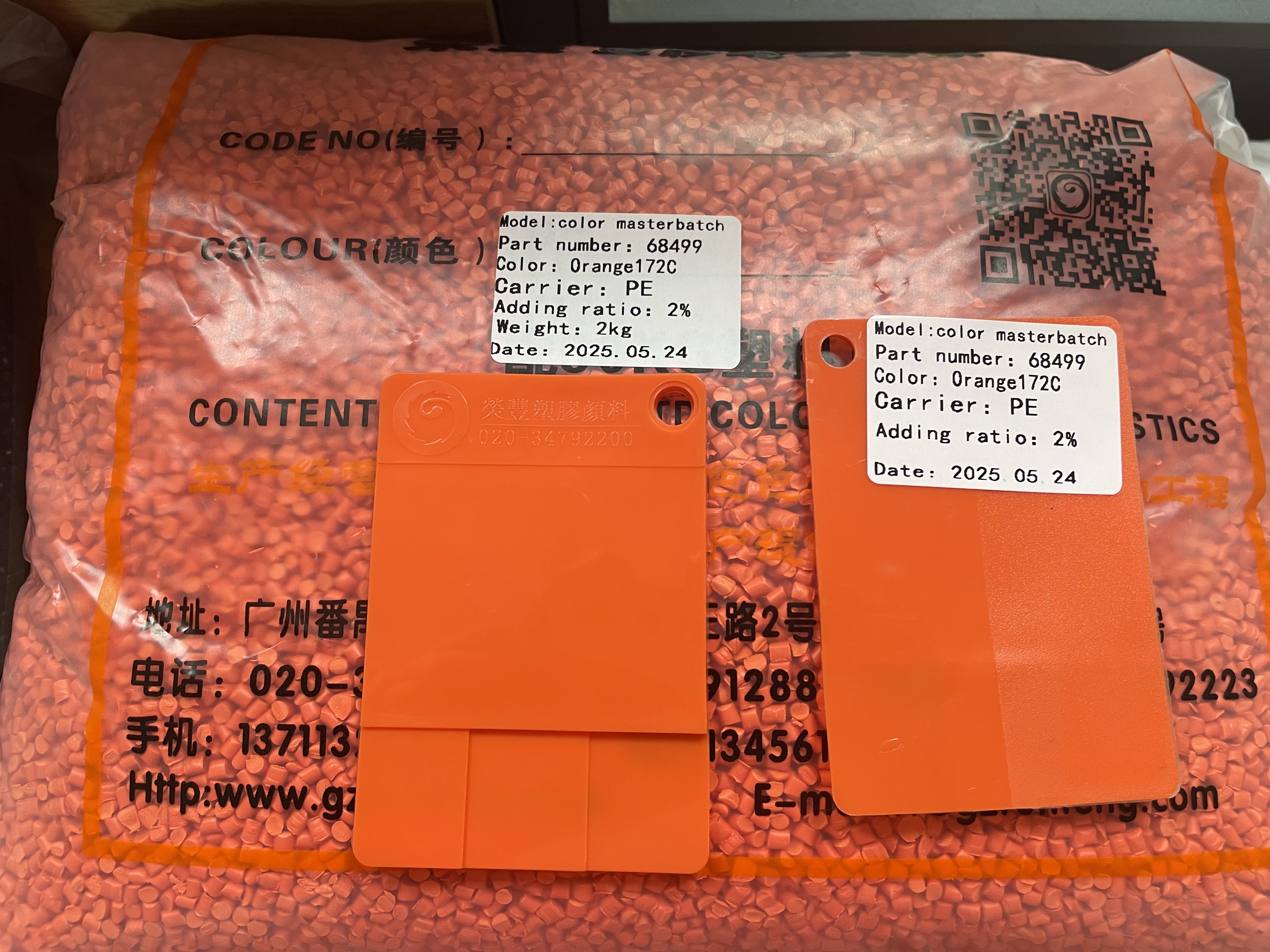

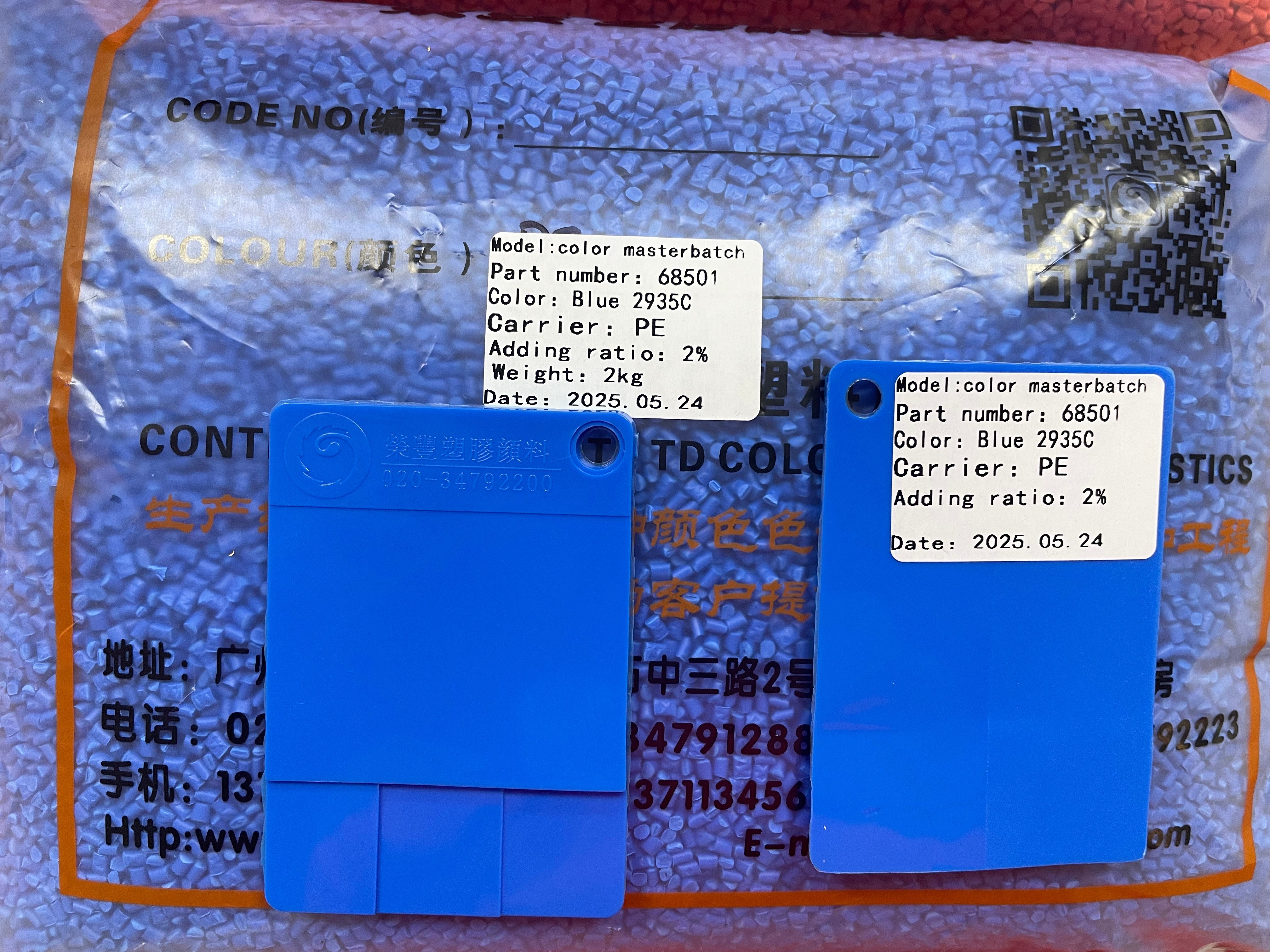

PE Color Masterbatch

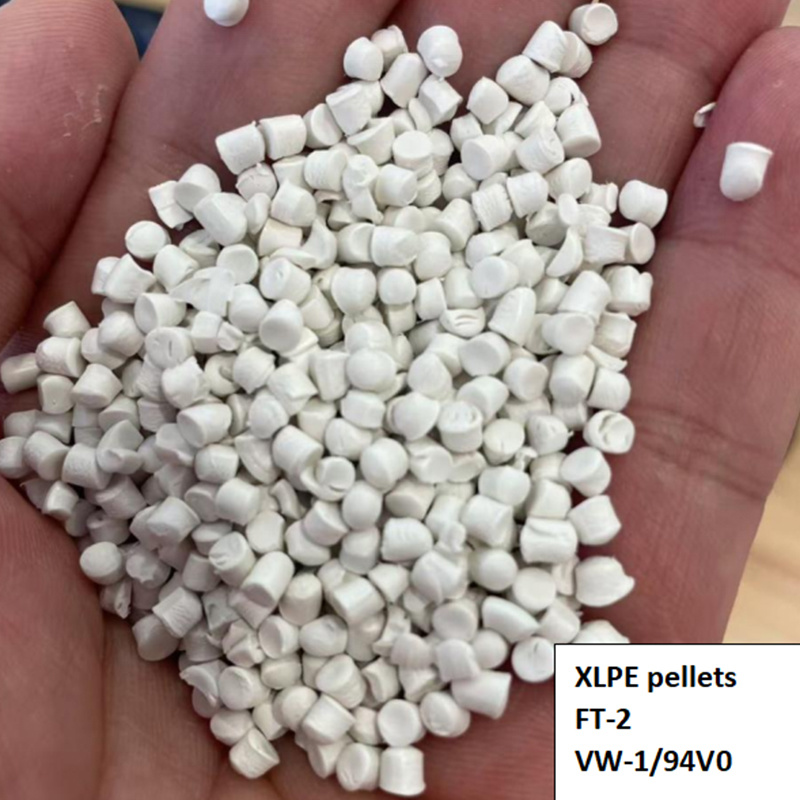

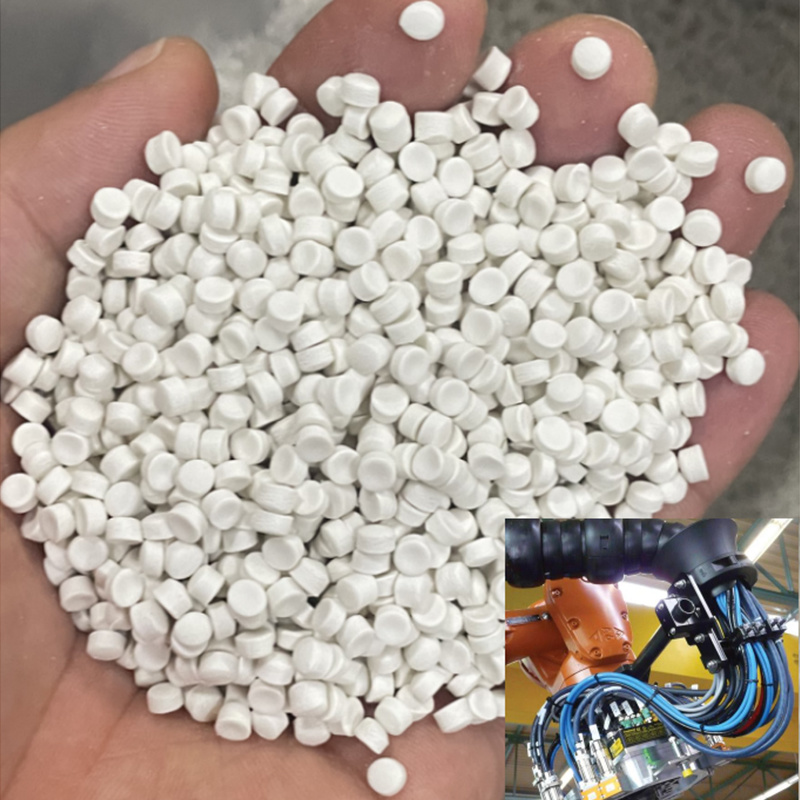

PE Color Masterbatch is a concentrated pigment mixture tailored for coloring polyethylene (PE) polymers. It combines a PE-compatible carrier resin, high-grade pigments, and additives to ensure uniform dispersion during processing. Suitable for blow molding, injection molding, film extrusion, and rotational molding, it delivers vivid, consistent colors while retaining PE’s properties like flexibility, chemical resistance, and durability. Customizable formulations can improve UV stability, anti-blocking, or antimicrobial features. Widely used in packaging, pipes, containers, and household products, PE masterbatch offers cost-effective, sustainable coloring solutions. Its optimized formulation adapts to PE’s processing temperatures (160–260°C), ensuring stability, minimal waste, and compatibility with both LDPE and HDPE grades for versatile industrial and consumer applications.

Categorize:

PE Masterbatch

Keyword:

PE Color Masterbatch: Enhancing Plastics with Vibrant Colors

In the world of plastics, color is not just an aesthetic choice; it plays a vital role in branding, product differentiation, and even functionality. Polyethylene (PE) color masterbatch is a crucial component in achieving vibrant and consistent colors in various plastic products. This article delves into the nature of PE color masterbatch, its applications, benefits, and future trends in the industry.

Understanding PE Color Masterbatch

PE color masterbatch is a concentrated mixture of pigments and additives encapsulated in a polyethylene carrier resin. This formulation allows manufacturers to easily incorporate color into their plastic products during the processing stage. Masterbatches are designed to provide uniform dispersion of colorants, ensuring that the final product exhibits the desired hue and shade.

The primary components of PE color masterbatch include the carrier resin, pigments, and additives. The carrier resin, usually made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), serves as the base material. Pigments provide the color, while additives can enhance properties such as UV resistance, heat stability, and flow characteristics.

Applications of PE Color Masterbatch

PE color masterbatch is widely used across various industries due to its versatility and effectiveness. One of the most common applications is in the packaging industry, where colored plastics are essential for branding and product recognition. For example, food packaging often uses specific colors to signify freshness or flavor, while consumer goods packaging utilizes vibrant colors to attract attention on store shelves.

Another significant application of PE color masterbatch is in the automotive industry. Colored plastics are employed in interior and exterior components, contributing not only to aesthetics but also to safety and visibility. For instance, colored bumpers and trims can enhance the overall look of a vehicle while also providing essential signaling in low-light conditions.

In the construction sector, PE color masterbatch is used in products such as pipes, roofing materials, and insulation. The ability to incorporate specific colors can aid in identifying different types of materials or applications, making it easier for professionals to select the right products for their projects.

Benefits of Using PE Color Masterbatch

The use of PE color masterbatch offers numerous advantages to manufacturers and end-users alike. One of the most significant benefits is consistency in color. Masterbatches ensure that the color is uniformly distributed throughout the plastic, reducing the risk of color variations that can occur when using powdered pigments.

Another advantage is the ease of use. PE color masterbatch can be easily incorporated into the production process, requiring minimal adjustments to existing machinery. This ease of use translates to reduced production times and lower costs, making it an attractive option for manufacturers.

Furthermore, PE color masterbatch allows for greater flexibility in color choices. Manufacturers can create custom colors tailored to specific branding needs, enabling them to stand out in a competitive market. This customization can be particularly beneficial for companies looking to create unique products or limited-edition lines.

Environmental Considerations

As the world becomes increasingly aware of environmental issues, the plastics industry is also evolving. The production and use of PE color masterbatch can align with sustainability goals through the incorporation of eco-friendly pigments and additives. Many manufacturers are now offering biodegradable or recyclable options, helping to reduce the environmental impact of plastic products.

Additionally, using masterbatches can contribute to waste reduction. By achieving the desired color in a more efficient manner, manufacturers can minimize the amount of scrap material generated during production. This efficiency not only benefits the environment but also improves the overall economics of the manufacturing process.

Future Trends in PE Color Masterbatch

The future of PE color masterbatch is promising, with several trends expected to shape its development. One of the most notable trends is the increasing demand for high-performance color masterbatches. As industries continue to seek advanced materials that can withstand harsh conditions, manufacturers will need to innovate and create masterbatches that enhance the durability and longevity of colored plastics.

Another trend is the rise of digital color matching technology. This technology allows manufacturers to accurately replicate specific colors using digital tools, streamlining the color selection process. As a result, the turnaround time for developing new products will decrease, enabling companies to respond quickly to market demands.

Moreover, the integration of smart technologies into the production process is anticipated to revolutionize the industry. The use of artificial intelligence and machine learning can optimize color formulations and processing conditions, resulting in improved efficiency and product quality.

Conclusion

PE color masterbatch is an essential component in the plastics industry, providing vibrant colors and enhancing the visual appeal of various products. Its versatility and ease of use make it a preferred choice for manufacturers across multiple sectors, including packaging, automotive, and construction. As the industry evolves, the focus on sustainability, high-performance materials, and technological advancements will continue to drive innovation in PE color masterbatch. With these developments, the future looks bright for colored plastics, ensuring they remain an integral part of our everyday lives.

Next

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.