PRODUCTS

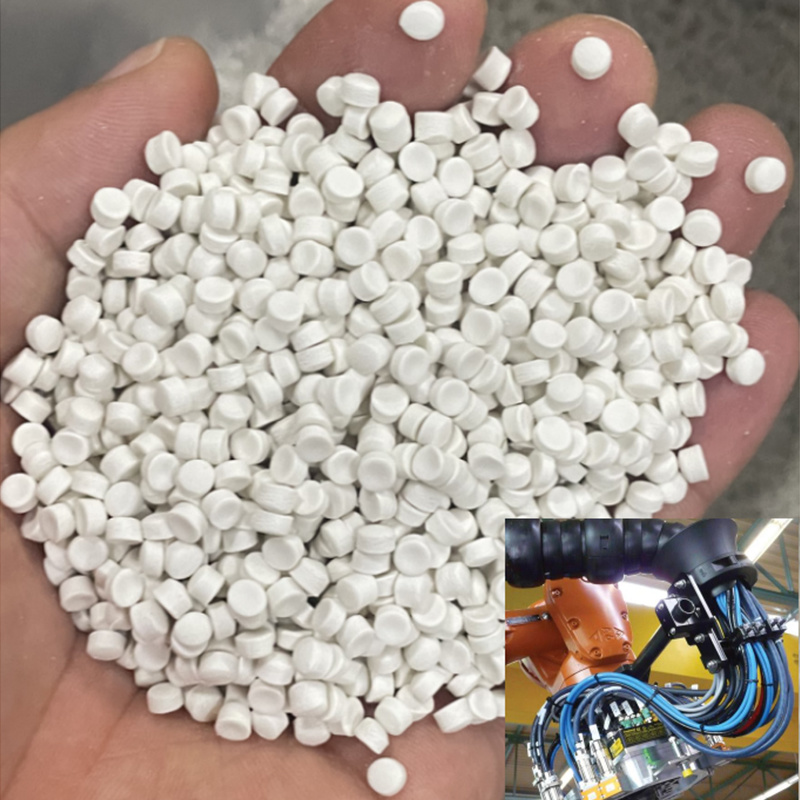

XLPE Color Masterbatch for Wires

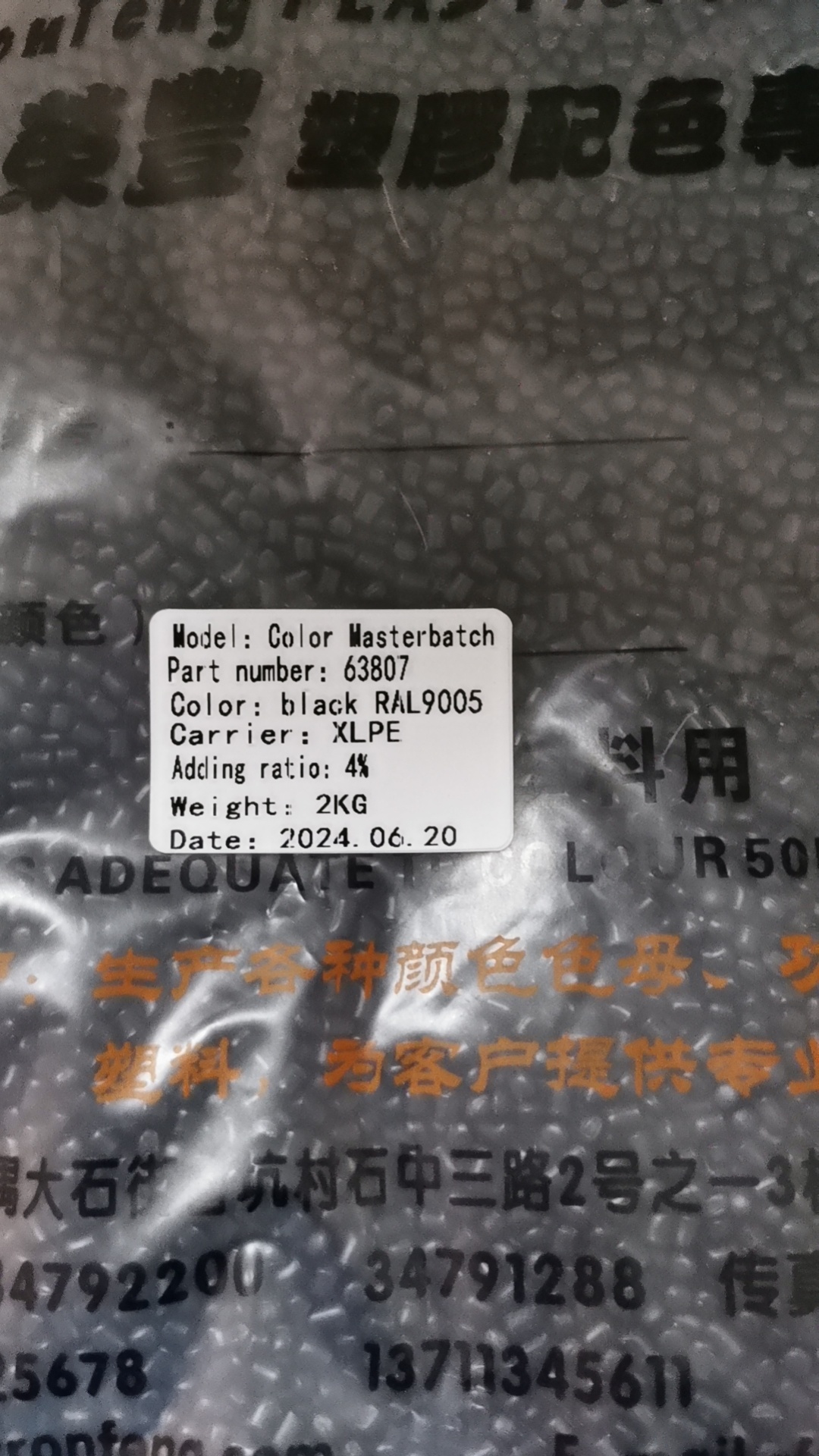

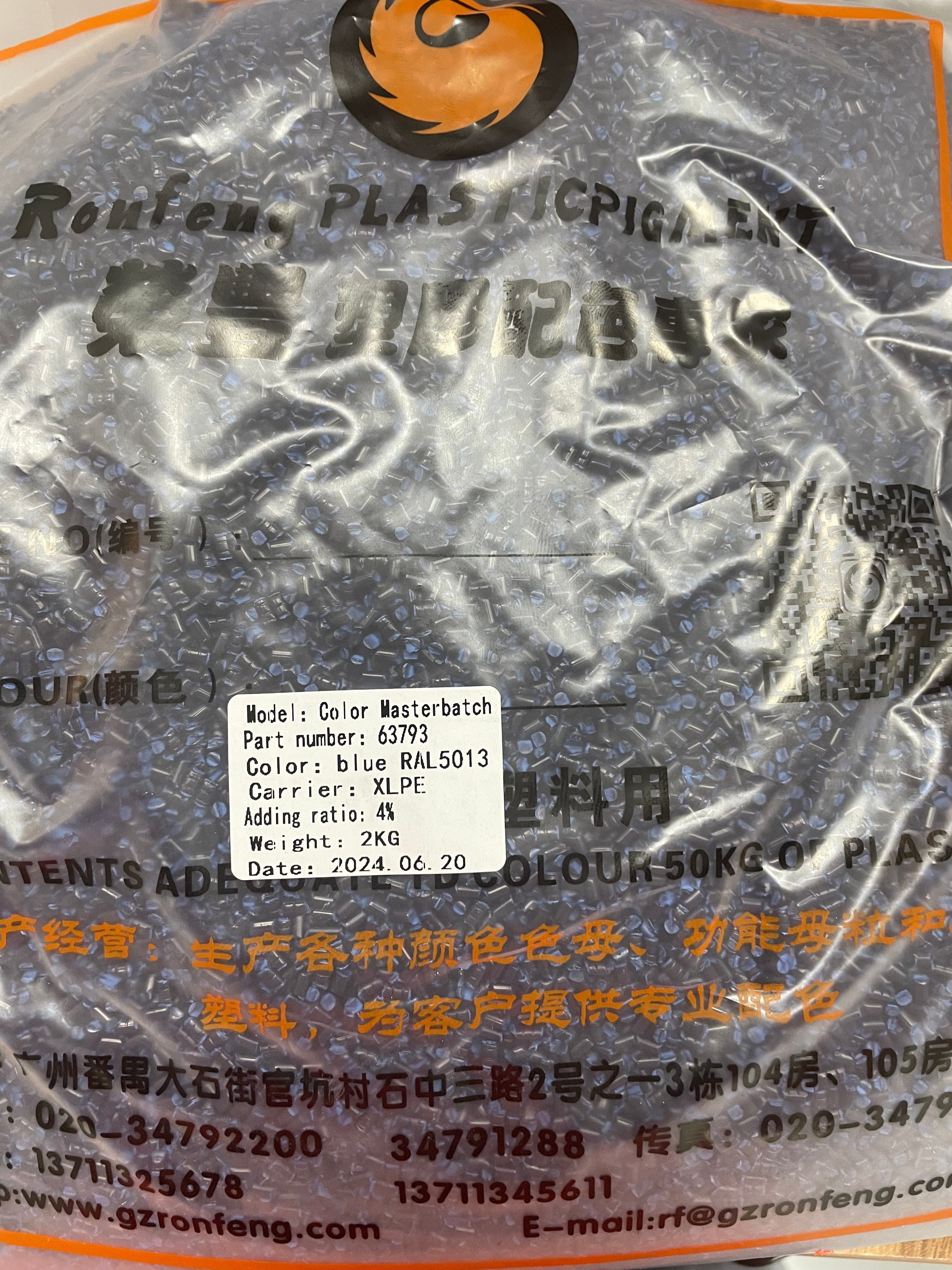

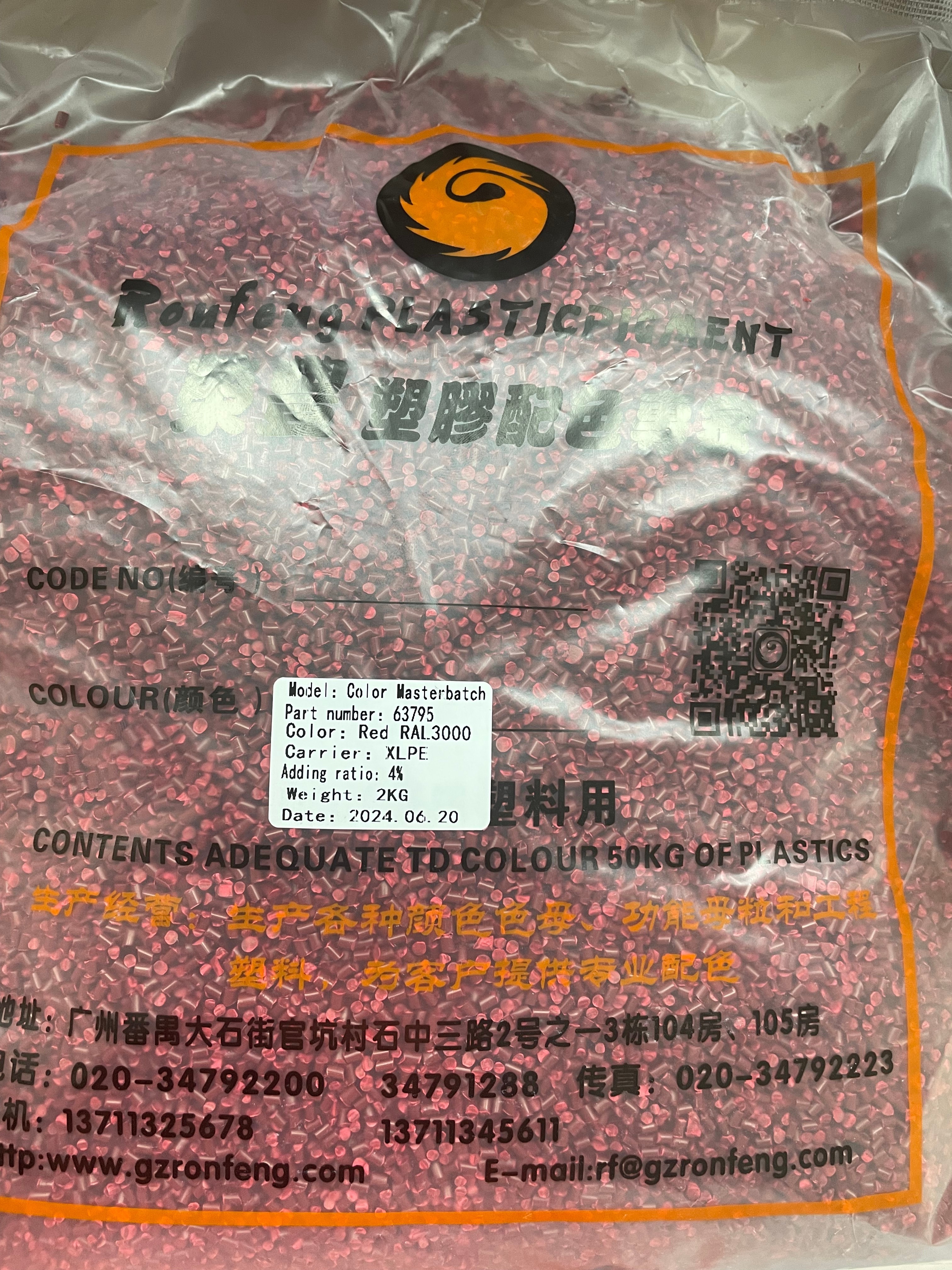

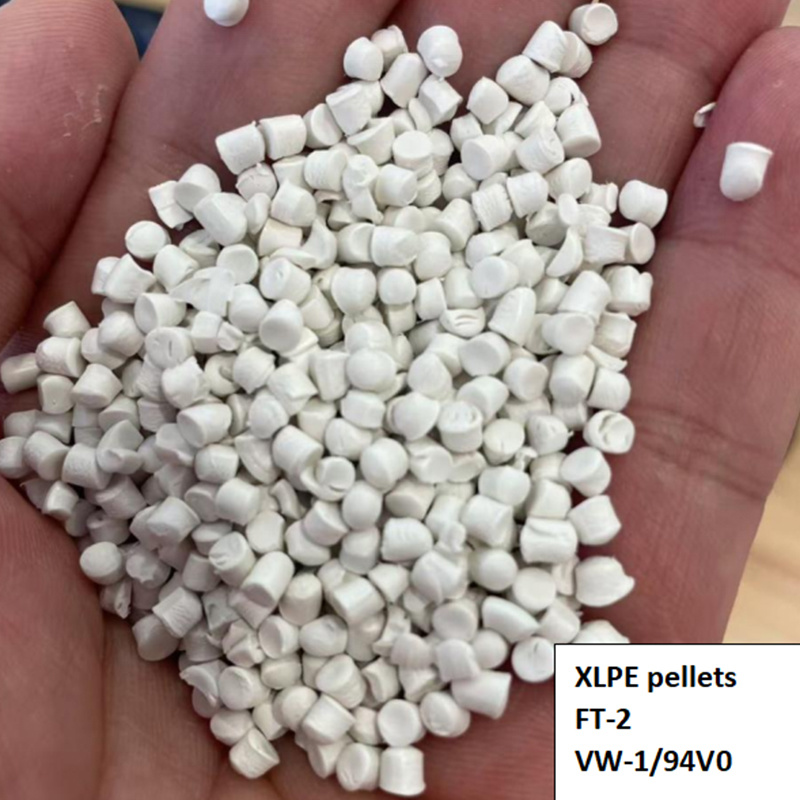

XLPE (Cross-Linked Polyethylene) color masterbatch is a concentrated mixture of pigments/dispersants within a specialized XLPE-compatible carrier resin. It's added during wire/cable extrusion to impart consistent, durable coloration to the insulation or jacketing layer. Key requirements include: High Thermal Stability: Must withstand XLPE processing temperatures and the crosslinking step (often peroxide-induced or steam cure). Excellent Dispersion: Ensures uniform color without defects impacting insulation integrity. Compatibility: Carrier resin must fuse seamlessly with the base XLPE compound. Electrical Properties: Must not significantly degrade XLPE's crucial dielectric strength and insulation resistance. Light & Weather Fastness: Colors must resist fading from UV exposure and environmental factors over the cable's lifespan. Masterbatches ensure identification, branding, and safety compliance (e.g., phase coding).

Categorize:

XLPE XLPO TPU TPE PUR PVC Masterbatch for Wires

Keyword:

**XLPE Color Masterbatch for Wires**

In the ever-evolving world of cable manufacturing, the choice of materials plays a crucial role in determining the performance, durability, and aesthetic appeal of the final product. Among the various materials available, cross-linked polyethylene (XLPE) has gained significant popularity, especially when combined with color masterbatches. This article delves into the significance of XLPE color masterbatch for wires, exploring its composition, benefits, applications, and future prospects.

**Understanding XLPE and Color Masterbatches**

Cross-linked polyethylene (XLPE) is a type of polyethylene that has been chemically or physically cross-linked to enhance its properties. This process results in a material that exhibits superior thermal stability, chemical resistance, and electrical insulation properties. XLPE is widely used in the insulation and sheathing of wires and cables, making it an ideal choice for various electrical applications.

Color masterbatches, on the other hand, are concentrated mixtures of pigments and additives encapsulated in a carrier resin. They are used to impart color to plastics and other materials during the manufacturing process. When combined with XLPE, color masterbatches not only enhance the visual appeal of wires but also contribute to their overall performance.

**Benefits of XLPE Color Masterbatch for Wires**

1. **Enhanced Aesthetics**: One of the primary advantages of using color masterbatches is the ability to create visually appealing products. Wires can be produced in a variety of colors, allowing manufacturers to cater to specific market demands and enhance brand identity. This is particularly important in industries where color coding is essential for safety and identification purposes.

2. **Improved Performance**: XLPE itself is known for its excellent electrical properties. When color masterbatches are incorporated, they can improve the overall performance of the wire. The addition of specific additives in the masterbatch can enhance UV resistance, flame retardancy, and even anti-static properties, making the wires safer and more durable.

3. **Cost-Effectiveness**: Using color masterbatches can be a cost-effective solution for manufacturers. Instead of applying a separate coating or paint to achieve the desired color, integrating the color during the extrusion process can save time and reduce production costs. This efficient method also minimizes waste and ensures a uniform color throughout the wire.

4. **Environmental Considerations**: As industries move towards more sustainable practices, the use of eco-friendly color masterbatches has gained traction. Many manufacturers are now producing color masterbatches that are free from harmful substances, making them safer for the environment. XLPE itself is also recyclable, which aligns with the growing emphasis on sustainability in manufacturing.

**Applications of XLPE Color Masterbatch in Wires**

The applications of XLPE color masterbatch are vast, spanning various industries and sectors. Some of the notable applications include:

1. **Electrical Wiring**: In residential and commercial buildings, electrical wiring often requires color-coded insulation to indicate different functions. XLPE color masterbatches allow manufacturers to produce wires that meet these requirements while ensuring optimal performance and safety.

2. **Automotive Industry**: The automotive sector utilizes XLPE color masterbatch for wiring harnesses and electrical components. The ability to produce wires in specific colors helps with organization and identification, which is critical for maintenance and repairs.

3. **Telecommunications**: In telecommunications, cables often need to be color-coded for efficient installation and maintenance. XLPE color masterbatches provide the necessary color consistency and durability, ensuring that the cables can withstand harsh environmental conditions.

4. **Industrial Applications**: Many industrial settings require robust wiring solutions that can endure extreme temperatures and chemical exposure. XLPE color masterbatches can enhance the resilience of wires, making them suitable for heavy-duty applications.

**Future Prospects of XLPE Color Masterbatch for Wires**

As technology advances and consumer demands evolve, the future of XLPE color masterbatch in wire manufacturing looks promising. Research and development are focusing on creating more advanced formulations that offer even greater benefits, such as enhanced thermal stability and resistance to environmental stressors.

Moreover, the trend towards automation and smart technologies in manufacturing is likely to influence the production of XLPE color masterbatches. The integration of smart manufacturing techniques can streamline the production process, reduce costs, and improve product quality.

Sustainability will also remain a key focus area. As regulations become stricter and consumers demand more eco-friendly products, manufacturers will continue to explore innovative ways to produce color masterbatches that are both effective and environmentally responsible.

**Conclusion**

In conclusion, XLPE color masterbatch represents a significant advancement in the field of wire manufacturing. By combining the superior properties of XLPE with the aesthetic and functional benefits of color masterbatches, manufacturers can produce wires that not only meet industry standards but also cater to consumer preferences. As the industry continues to evolve, the integration of XLPE color masterbatch will undoubtedly play a vital role in shaping the future of electrical wiring and cable solutions. The blend of performance, aesthetics, and sustainability makes XLPE color masterbatch an indispensable component in modern wire manufacturing.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.