PRODUCTS

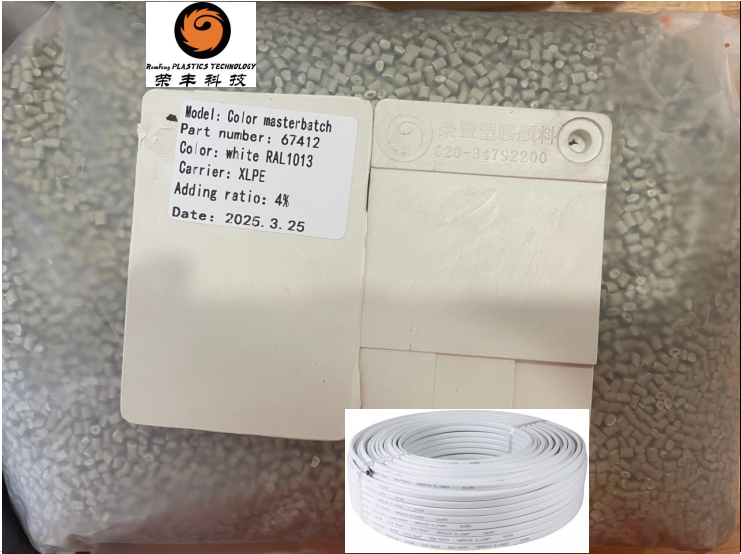

XLPO Color Masterbatch for Wires

XLPO (Cross-Linked Polyolefin) color masterbatch delivers vivid, durable coloration for wires and cables insulated with cross-linked polyolefin blends. Added during extrusion, it must withstand high processing and crosslinking temperatures (commonly peroxide-induced or silane-cured) without degradation. Essential properties include: Exceptional Thermal Stability: Resists temperatures exceeding those of standard XLPE, often >250°C during curing/service. Perfect Compatibility & Fusion: Seamlessly integrates with diverse XLPO base resins (PE, EVA, EBA blends). Superior Dispersion: Ensures flawless color uniformity without compromising insulation integrity. Electrical Integrity: Must not degrade the XLPO's critical dielectric strength and insulation resistance. Long-Term Durability: Provides UV, weather, and chemical resistance for harsh environments like automotive (EV cables) or industrial applications.

Categorize:

XLPE XLPO TPU TPE PUR PVC Masterbatch for Wires

Keyword:

**XLPO Color Masterbatch for Wires**

In the ever-evolving world of manufacturing, the demand for high-quality, aesthetically pleasing, and durable products is at an all-time high. One area where this demand is particularly pronounced is in the production of wires and cables. Wires are essential components in various applications, from electrical wiring to automotive and telecommunications. To meet both functional and aesthetic requirements, manufacturers increasingly turn to color masterbatches, with XLPO Color Masterbatch standing out as a premier choice.

**What is XLPO Color Masterbatch?**

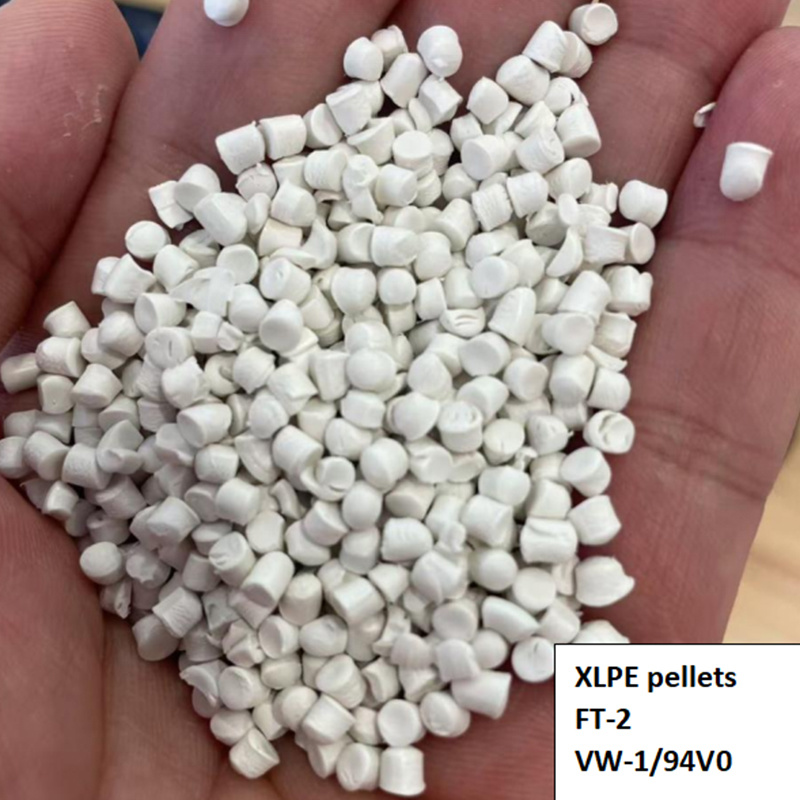

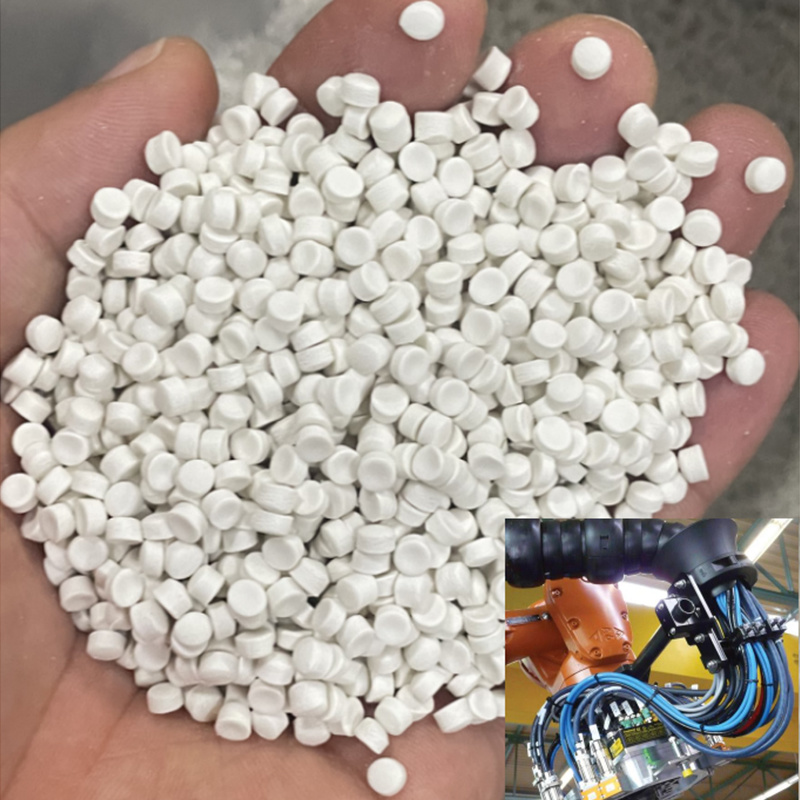

XLPO Color Masterbatch is a concentrated mixture of pigments and additives encapsulated in a polymer carrier. This masterbatch is specifically designed for use in wire and cable manufacturing, providing vibrant colors and excellent processing characteristics. The "XLPO" designation refers to the cross-linked polyolefin material that serves as the carrier for the pigments. This unique formulation ensures that the color masterbatch can withstand the rigorous conditions often encountered in wire production, such as high temperatures and mechanical stress.

**Advantages of XLPO Color Masterbatch**

One of the primary advantages of XLPO Color Masterbatch is its ability to provide consistent color quality. In industries where color coding is crucial for safety and identification, such as electrical wiring, consistency is paramount. XLPO Color Masterbatch ensures that every batch produced meets the same high standards, allowing manufacturers to maintain uniformity across their product lines.

Another significant benefit is the ease of use during the manufacturing process. XLPO Color Masterbatch can be easily incorporated into the extrusion or injection molding processes commonly used in wire production. This seamless integration not only saves time but also minimizes waste, making it an environmentally friendly choice. Additionally, the masterbatch is designed to disperse evenly within the polymer matrix, ensuring that the color is uniformly distributed throughout the wire.

**Durability and Performance**

In addition to its aesthetic benefits, XLPO Color Masterbatch enhances the performance characteristics of the wires it colors. The masterbatch is engineered to provide excellent thermal stability, which is critical during the manufacturing process. This stability ensures that the colors do not degrade or change during high-temperature processing, resulting in wires that maintain their intended appearance and functionality.

Moreover, XLPO Color Masterbatch is formulated to be UV resistant, which is essential for wires that will be exposed to sunlight or other forms of ultraviolet radiation. This resistance helps prevent fading and degradation over time, ensuring that the wires retain their color and structural integrity even in harsh environmental conditions.

**Applications of XLPO Color Masterbatch**

The versatility of XLPO Color Masterbatch allows it to be used in a wide range of applications. In the electrical industry, color-coded wires are essential for safety and identification. XLPO Color Masterbatch can be used to produce wires that meet specific color standards, aiding in the easy identification of various circuits and connections.

In the automotive sector, the demand for high-quality, durable wires is equally critical. XLPO Color Masterbatch can be used to create aesthetically pleasing wiring harnesses that not only look good but also perform well under the demanding conditions of automotive environments.

Telecommunications is another area where XLPO Color Masterbatch shines. With the increasing complexity of communication systems, the need for color-coded cables is essential for organization and troubleshooting. The masterbatch can be used to produce cables that are both visually appealing and functionally reliable.

**Environmental Considerations**

As sustainability becomes a key focus for many industries, the environmental impact of materials used in manufacturing is under scrutiny. XLPO Color Masterbatch is designed with eco-friendliness in mind. By minimizing waste during the production process and ensuring a longer lifespan for the finished products, this masterbatch aligns with the growing trend toward sustainable manufacturing practices.

Additionally, manufacturers can benefit from reduced energy consumption during the processing of XLPO Color Masterbatch. The efficient dispersion of pigments within the polymer matrix means that less energy is required to achieve the desired color intensity, further contributing to a more sustainable production process.

**Conclusion**

In conclusion, XLPO Color Masterbatch for wires represents a significant advancement in the field of wire manufacturing. Its combination of vibrant colors, excellent processing characteristics, and durability makes it an ideal choice for a variety of applications. As industries continue to prioritize both functionality and aesthetics, the use of high-quality color masterbatches like XLPO will undoubtedly play a crucial role in shaping the future of wire and cable production.

Manufacturers looking to enhance their product offerings while meeting stringent quality and environmental standards will find that XLPO Color Masterbatch not only meets but exceeds their expectations. With its unique formulation and versatile applications, XLPO Color Masterbatch is poised to become a staple in the wire manufacturing industry, ensuring that products are not only functional but also visually appealing and durable. As the demand for high-quality wires continues to grow, so too will the importance of innovative solutions like XLPO Color Masterbatch.

Next

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.