PRODUCTS

Anti Static Additive Masterbatch

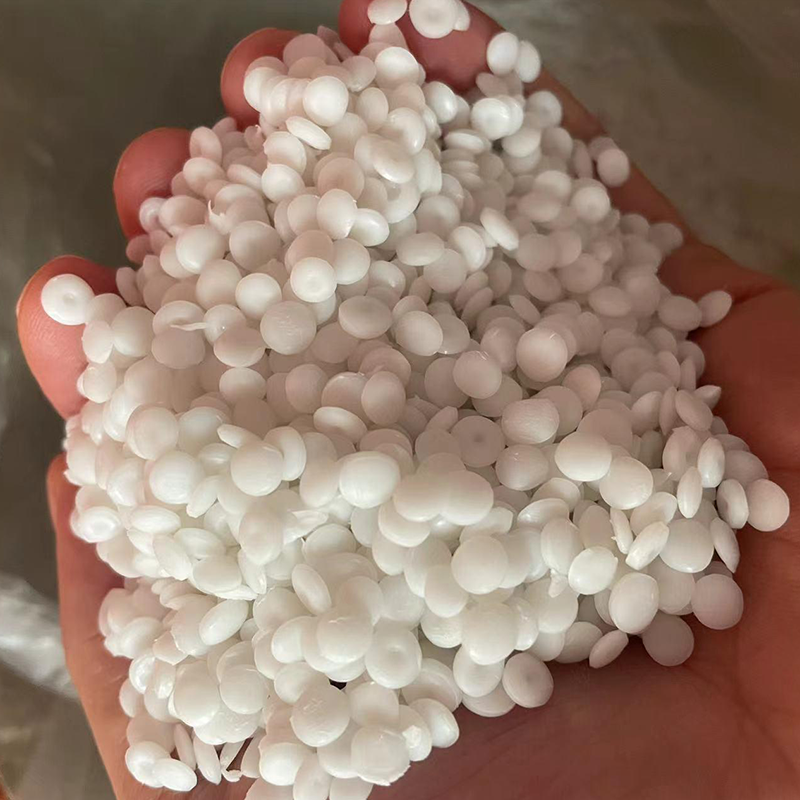

PE Anti-Static Additive Masterbatch Concentrated masterbatch incorporating 15-40% specialized anti-static agents (e.g., ethoxylated amines, glycerol esters) into PE carriers, designed to impart permanent or migratory static dissipation in films, packaging, and industrial parts. Achieves surface resistivity of 10⁸–10¹² Ω/sq. Key Features Rapid Charge Dissipation: Reduces static decay to <2 seconds (ESD-safe per ANSI/ESD S20.20). Thermal Stability: Compatible with processing at 160–230°C without degradation. Low Migration: Non-oily formulation prevents surface bloom or contamination4. Technical Benefits Prevents dust adhesion, spark risks, and equipment jamming. Maintains clarity in transparent films (no haze). Minimal impact on mechanical properties (tensile strength ±5%). Applications & Dosage Dosage: 2–5% in films, 5–10% in rigid parts. Uses: FIBC bags, electronic packaging, automotive fuel tanks, conveyor components.

Categorize:

Additive Masterbatch

Keyword:

Supporting Products

masterbatch

In today's fast-paced technological landscape, the demand for materials that can withstand various environmental conditions has increased significantly. One of the critical challenges in industries such as electronics, packaging, and textiles is the buildup of static electricity. This phenomenon can lead to product damage, operational inefficiencies, and safety hazards. To combat these issues, manufacturers have turned to anti-static additive masterbatches as a practical solution. This article will explore what anti-static additive masterbatches are, their applications, benefits, and the future of static control solutions.

Anti-static additive masterbatches are concentrated mixtures of additives that are incorporated into polymers to impart anti-static properties. These masterbatches typically consist of a polymer carrier and various anti-static agents, which can be ionic, non-ionic, or a combination of both. When blended with base polymers, these additives help to reduce the accumulation of static charges on the surface of materials, thereby mitigating the risk of static discharge.

The importance of controlling static electricity cannot be overstated. In the electronics industry, for instance, static discharge can damage sensitive components, leading to costly product failures and recalls. Similarly, in packaging applications, static can cause materials to cling together or attract dust and contaminants, compromising product integrity. In textiles, static can result in discomfort for consumers and create challenges in the manufacturing process. Therefore, the incorporation of anti-static additive masterbatches is crucial for ensuring product reliability and safety.

One of the primary applications of anti-static additive masterbatches is in the production of plastic films and sheets. These materials are widely used in packaging applications, where static control is essential to prevent product sticking and contamination. By integrating anti-static masterbatches into the manufacturing process, producers can enhance the performance of their films, ensuring that they remain free from static-related issues throughout their lifecycle.

Another significant application is in the electronics industry, where anti-static masterbatches are used in the production of various components, including casings and connectors. These materials must meet stringent anti-static requirements to protect sensitive electronic devices from potential damage. By utilizing anti-static additive masterbatches, manufacturers can produce components that are not only durable but also safe from static-related hazards.

In the automotive sector, anti-static masterbatches play a vital role in the production of interior components, such as dashboards and trims. These components often experience friction and movement, which can generate static electricity. By incorporating anti-static additives, manufacturers can ensure that these parts remain safe and functional, contributing to overall vehicle safety and performance.

The benefits of using anti-static additive masterbatches extend beyond mere static control. These additives can also enhance the overall performance of the base polymers. For example, some anti-static agents can improve the mechanical properties of plastics, such as impact resistance and tensile strength. Additionally, they can help improve the surface finish of products, making them more visually appealing to consumers.

Moreover, anti-static masterbatches offer a cost-effective solution for manufacturers looking to enhance the performance of their products. By using masterbatches, companies can easily incorporate anti-static properties into their production processes without the need for extensive modifications to existing equipment. This not only saves time and resources but also ensures consistency in product quality.

As technology continues to evolve, the future of anti-static additive masterbatches looks promising. Research and development in this field are focused on creating more efficient and environmentally friendly additives. For instance, there is a growing trend towards the use of bio-based and biodegradable anti-static agents, which align with the increasing demand for sustainable materials. Additionally, advancements in nanotechnology are paving the way for the development of new anti-static solutions that can offer enhanced performance and durability.

In conclusion, anti-static additive masterbatches are essential components in a variety of industries, providing a reliable solution for static control. Their applications in packaging, electronics, and automotive sectors highlight their versatility and importance in ensuring product safety and performance. As manufacturers continue to seek innovative solutions to combat static electricity, the development of more efficient and sustainable anti-static additives will undoubtedly play a significant role in shaping the future of material science. By understanding and utilizing these masterbatches, companies can enhance their products' reliability, improve operational efficiency, and ultimately provide better value to their customers.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.