PRODUCTS

Flame Retardant Additive Masterbatch

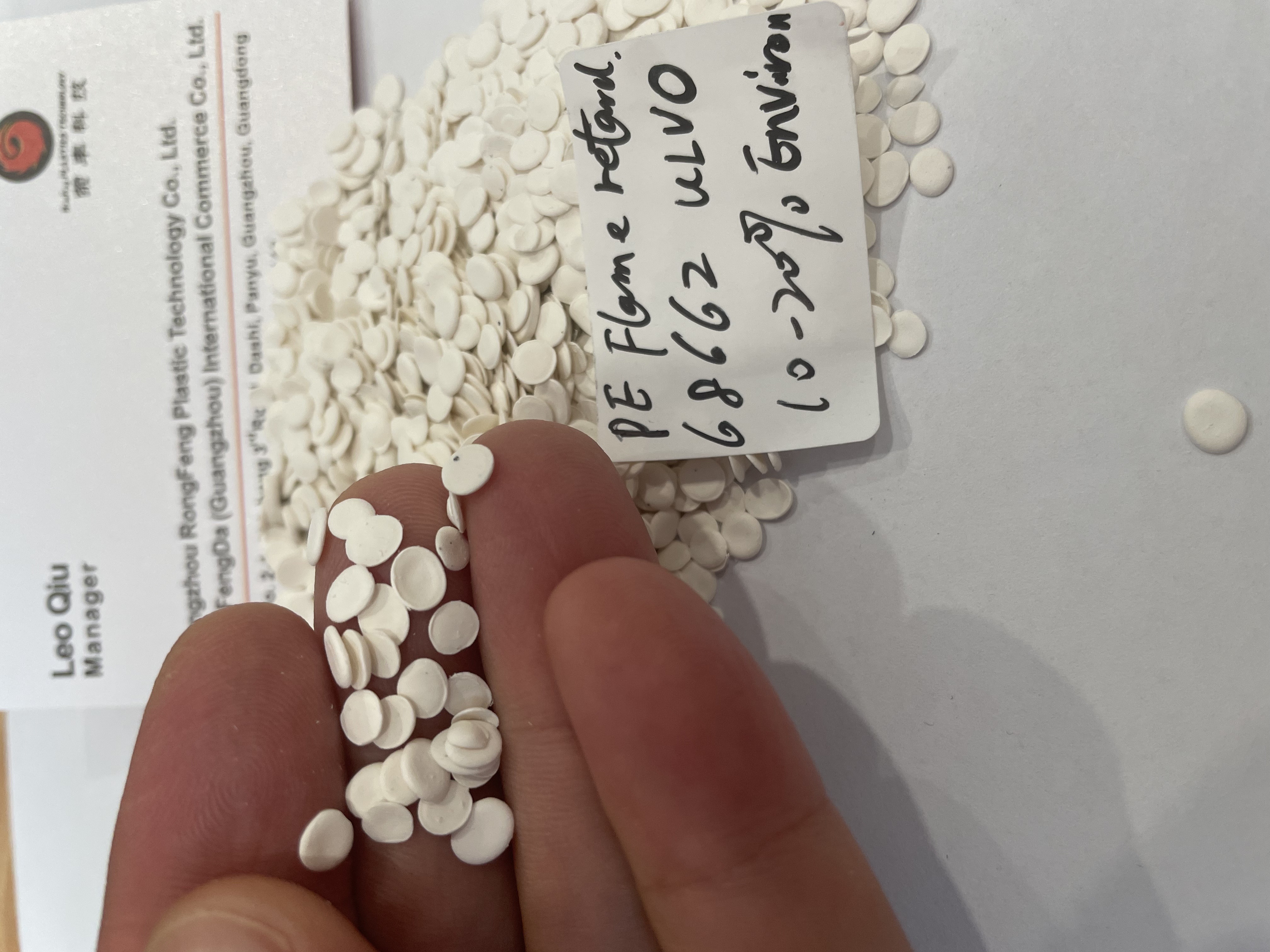

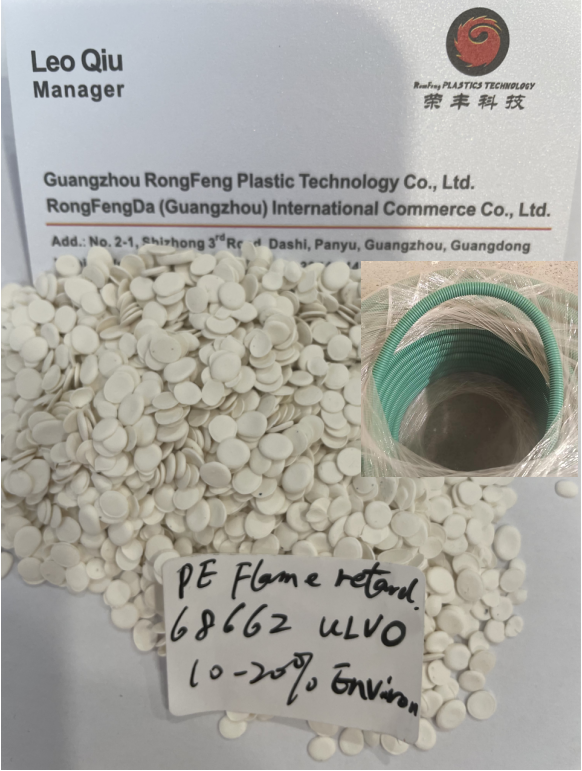

Flame Retardant Additive Masterbatch Concentrated polymer carriers (e.g., PE, PP) loaded with 15–60% flame-retardant compounds, including halogen-free agents like aluminum trihydroxide (ATH) or synergistic phosphorus-nitrogen systems. These additives inhibit combustion by forming protective char layers and quenching free radicals during thermal exposure. Key Mechanisms Gas Phase Inhibition: Releases non-flammable gases (e.g., water vapor from ATH) to dilute oxygen. Char Formation: Creates insulating carbon barriers that shield substrates from heat/flames. Critical Performance Achieves UL94 V-0/V-1 ratings in polyolefins and engineering plastics. Thermal Stability: Processes at 180–260°C without decomposition. Low Smoke Emission: Halogen-free variants reduce toxic fume generation. Applications & Dosage Dosage: 5–20% in cables, 10–30% in electrical enclosures. Uses: Automotive connectors, building materials, electronic housings.

Categorize:

Additive Masterbatch

Keyword:

Supporting Products

masterbatch

Flame Retardant Additive Masterbatch

In an age where safety and performance are paramount, the demand for flame retardant materials has surged across various industries. Flame retardant additive masterbatches are essential components in the production of fire-resistant plastics, textiles, and other materials. This article explores the significance, composition, applications, and future trends of flame retardant additive masterbatches, providing a comprehensive understanding of their role in modern manufacturing.

**Understanding Flame Retardant Additive Masterbatches**

Flame retardant additive masterbatches are concentrated mixtures of flame retardant additives combined with a polymer carrier. These masterbatches are designed to be easily incorporated into the base polymer during processing, ensuring uniform distribution of the flame retardant properties throughout the final product. The primary purpose of these masterbatches is to reduce the flammability of materials, thereby enhancing safety and compliance with fire safety regulations.

The need for flame retardant materials arises from the increasing awareness of fire hazards in various environments, including residential, commercial, and industrial settings. Regulations and standards, such as those set by the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL), have further propelled the demand for flame retardant solutions.

**Composition of Flame Retardant Additive Masterbatches**

Flame retardant additive masterbatches typically consist of three main components: the flame retardant agent, the polymer carrier, and any additional additives that enhance performance.

1. **Flame Retardant Agents**: These are the active components that impart flame resistance to the material. They can be categorized into two main types: halogenated and non-halogenated. Halogenated flame retardants are effective but often face scrutiny due to environmental and health concerns. Non-halogenated options, such as phosphorous-based and inorganic flame retardants, are gaining popularity due to their lower toxicity and environmental impact.

2. **Polymer Carrier**: The polymer carrier is the base material that allows for the effective dispersion of flame retardant agents. Common carriers include polyethylene, polypropylene, and polystyrene. The choice of carrier depends on the final application and the processing conditions of the base polymer.

3. **Additives**: Additional components, such as processing aids, anti-oxidants, and colorants, may also be included to enhance the overall performance of the masterbatch. These additives can improve the processing characteristics and final appearance of the product.

**Applications of Flame Retardant Additive Masterbatches**

The versatility of flame retardant additive masterbatches allows for their use in a wide range of applications across different industries:

1. **Construction**: Flame retardant materials are crucial in the construction industry to ensure the safety of buildings and infrastructure. Applications include insulation materials, wall coverings, and roofing products.

2. **Automotive**: The automotive industry utilizes flame retardant masterbatches in various components, such as dashboards, seat covers, and electrical systems. These materials help protect passengers in the event of a fire and comply with stringent safety regulations.

3. **Textiles**: In the textile industry, flame retardant additive masterbatches are used in upholstery, curtains, and clothing, especially for commercial and institutional applications where fire safety is critical.

4. **Electronics**: The electronics sector employs flame retardant materials in devices and components to mitigate the risk of fire hazards. From circuit boards to casings, flame retardant masterbatches play a vital role in enhancing safety.

5. **Packaging**: Flame retardant additives are also finding their way into packaging materials, especially for products that require additional fire protection during transportation and storage.

**Challenges and Innovations in Flame Retardant Additive Masterbatches**

While flame retardant additive masterbatches offer significant benefits, there are challenges associated with their use. One major concern is the potential environmental impact of certain flame retardants, particularly halogenated compounds. As a result, manufacturers are increasingly focusing on developing non-toxic and environmentally friendly alternatives.

Innovation in flame retardant technology is also driving the development of new materials with improved performance characteristics. Researchers are exploring bio-based flame retardants derived from renewable resources, which can offer similar protection without the environmental drawbacks of traditional compounds. Additionally, advances in nanotechnology are enabling the creation of flame retardant masterbatches with enhanced properties and reduced loading levels.

**Future Trends in Flame Retardant Additive Masterbatches**

The future of flame retardant additive masterbatches looks promising, driven by evolving regulations and consumer demand for safer products. As industries continue to prioritize sustainability, the development of eco-friendly flame retardant solutions will become increasingly important.

Moreover, the integration of flame retardant masterbatches with other functional additives, such as antimicrobial agents and UV stabilizers, is expected to create multifunctional materials that meet a broader range of performance criteria.

The growth of smart materials and IoT (Internet of Things) applications may also lead to innovative flame retardant solutions that can monitor and respond to fire hazards in real-time.

**Conclusion**

Flame retardant additive masterbatches are a crucial component in the production of fire-resistant materials across various industries. Their ability to enhance safety while complying with stringent regulations makes them indispensable in today’s manufacturing landscape. As the industry continues to evolve, the focus on environmentally friendly solutions and innovative technologies will shape the future of flame retardant masterbatches, ensuring that they remain at the forefront of material safety and performance.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.