PRODUCTS

Glow in Dark Additive Masterbatch

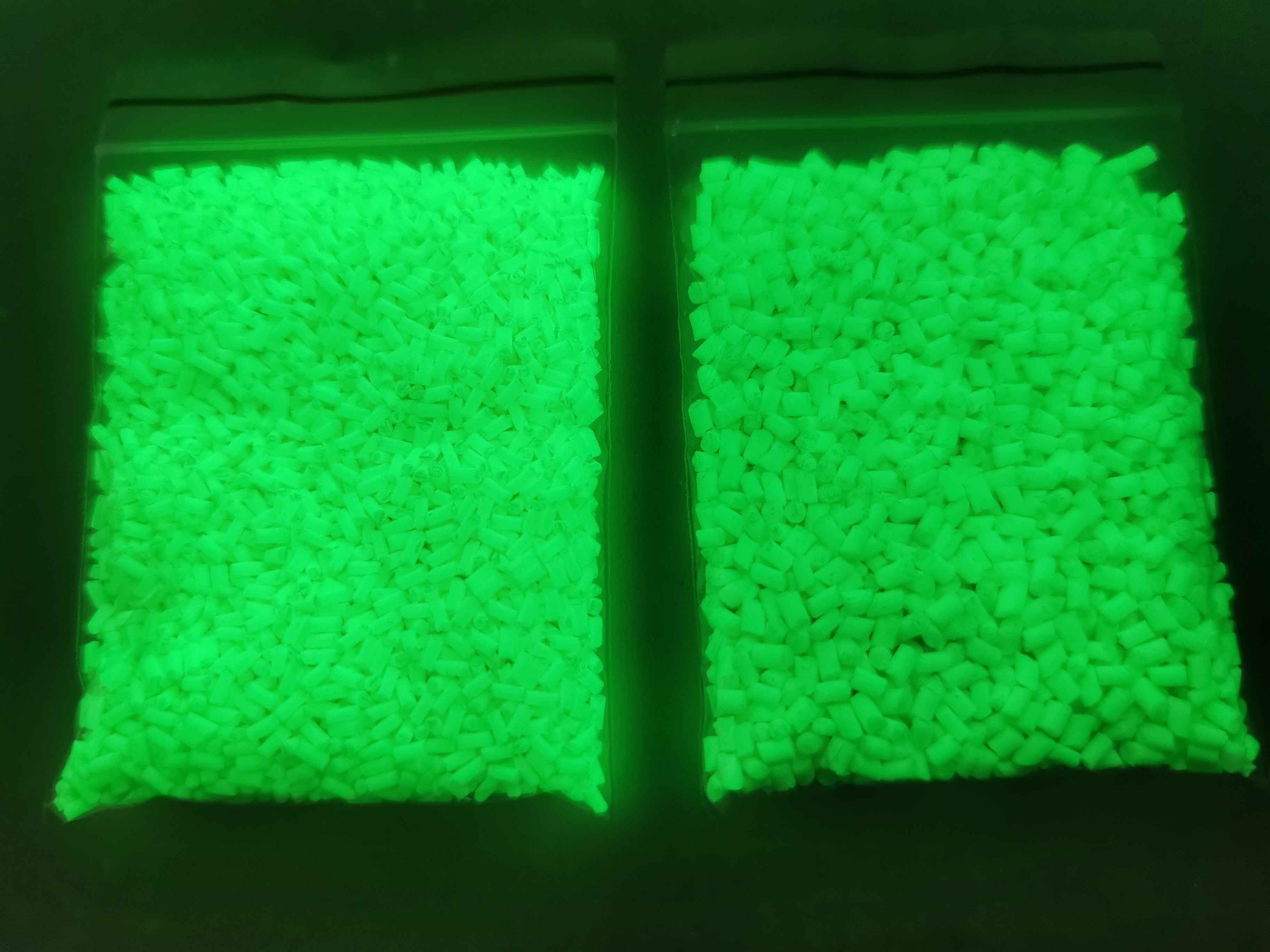

Glow in the dark masterbatch is a specialized additive used in plastic manufacturing to create luminescent products. It contains phosphorescent pigments, typically strontium aluminate, which absorb and store light energy, then emit a soft glow in darkness. This masterbatch is mixed with base polymers like PP, PE, TPU, PLA, PETG or ABS during injection molding or extrusion. Key applications include safety signs, toys, watch dials, and decorative items. The glow duration and intensity depend on pigment concentration and light exposure time. It's non-toxic, durable, and rechargeable under UV or sunlight. Manufacturers value its ease of processing and consistent dispersion. This innovative material combines functionality with aesthetic appeal for nighttime visibility solutions.

Categorize:

Additive Masterbatch

Keyword:

**Glow in Dark Additive Masterbatch**

The world of plastics and polymers has witnessed remarkable innovations over the years, one of which is the development of glow-in-the-dark additive masterbatches. These masterbatches are specialized formulations that incorporate luminescent pigments into plastic materials, enabling them to emit a soft glow in low-light conditions. This article explores the significance, applications, and advantages of glow-in-the-dark additive masterbatches.

**Understanding Glow in Dark Additive Masterbatch**

Glow in the dark masterbatch is a concentrated mixture of polymers and luminescent additives, which are typically phosphorescent pigments. These pigments absorb ambient light and release it slowly over time, creating a glow effect. The most commonly used materials for these pigments include strontium aluminate, zinc sulfide, and various other compounds. The masterbatch format allows for easy incorporation into various plastic resins during the manufacturing process.

The glow effect can vary in duration and intensity, depending on the type of pigment used and the duration of light exposure. High-quality masterbatches can provide a glow that lasts for several hours, making them ideal for a wide range of applications.

**Applications of Glow in Dark Additive Masterbatch**

The versatility of glow-in-the-dark masterbatches makes them suitable for various industries. One of the most prominent applications is in safety and emergency signage. For instance, exit signs, emergency lighting, and floor markings in buildings can utilize these masterbatches to ensure visibility during power outages or low-light conditions. This feature is particularly crucial in commercial buildings, schools, and hospitals, where safety is paramount.

In addition to safety applications, glow-in-the-dark masterbatches have found their way into consumer products. Toys, decorative items, and novelty gifts often incorporate these additives to create visually appealing effects. For example, glow-in-the-dark toys can provide children with a sense of wonder and excitement, while decorative items can enhance the ambiance of a room.

Another growing application is in the automotive industry. Glow-in-the-dark materials can be used in dashboard indicators, control buttons, and even exterior vehicle features to enhance visibility and aesthetics. As car manufacturers seek to differentiate their products, the incorporation of luminescent materials presents an innovative solution.

**Advantages of Using Glow in Dark Additive Masterbatch**

The incorporation of glow-in-the-dark masterbatches into plastic products offers several advantages. First and foremost, they enhance safety. By providing illumination in the dark, these materials help prevent accidents and guide individuals to safety during emergencies. This safety feature is invaluable in various settings, including public buildings, transportation hubs, and outdoor areas.

Furthermore, glow-in-the-dark masterbatches are easy to use and integrate into existing manufacturing processes. They can be blended with different types of plastics, including polyethylene, polypropylene, and polystyrene, without significant changes to the production line. This flexibility allows manufacturers to adopt luminescent materials without overhauling their entire production process.

Additionally, these masterbatches are available in various colors and glow intensities, allowing for customization to meet specific design requirements. This customization can be particularly beneficial for branding and marketing purposes, as companies can create unique products that stand out in the market.

**Environmental Considerations**

As with any additive, environmental considerations are essential. Many glow-in-the-dark masterbatches are designed to be non-toxic and safe for use in consumer products. However, manufacturers must ensure that the pigments used are compliant with environmental regulations and standards. This compliance is crucial for products intended for children's use or those that may come into contact with food.

Moreover, the longevity of the glow effect can contribute to sustainability. By providing illumination without the need for electricity, these materials can reduce energy consumption in specific applications. For instance, glow-in-the-dark safety signs can minimize the need for additional lighting, thereby contributing to energy savings in buildings.

**Future Trends in Glow in Dark Additive Masterbatch**

As technology advances, the future of glow-in-the-dark additive masterbatches appears promising. Researchers are continually exploring new materials and formulations that enhance the glow effect, increase durability, and improve the environmental footprint of these products. Innovations in phosphorescent materials may lead to longer-lasting and more vibrant glow effects, making them even more appealing for various applications.

Additionally, the growing demand for unique and customizable products presents opportunities for manufacturers to develop specialized masterbatches that cater to niche markets. The integration of smart technologies, such as sensors that activate the glow effect in response to specific stimuli, could also be a potential area of development.

**Conclusion**

Glow-in-the-dark additive masterbatches represent a fascinating intersection of safety, innovation, and creativity in the plastics industry. Their ability to provide illumination in dark environments makes them invaluable for safety applications, while their versatility allows for use in a wide range of consumer products. As manufacturers continue to explore new materials and technologies, the potential for glow-in-the-dark masterbatches will only expand, offering exciting possibilities for the future. By balancing performance with environmental considerations, these masterbatches can contribute to a safer and more visually engaging world.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.