PRODUCTS

Laser Marking Masterbatch for POM

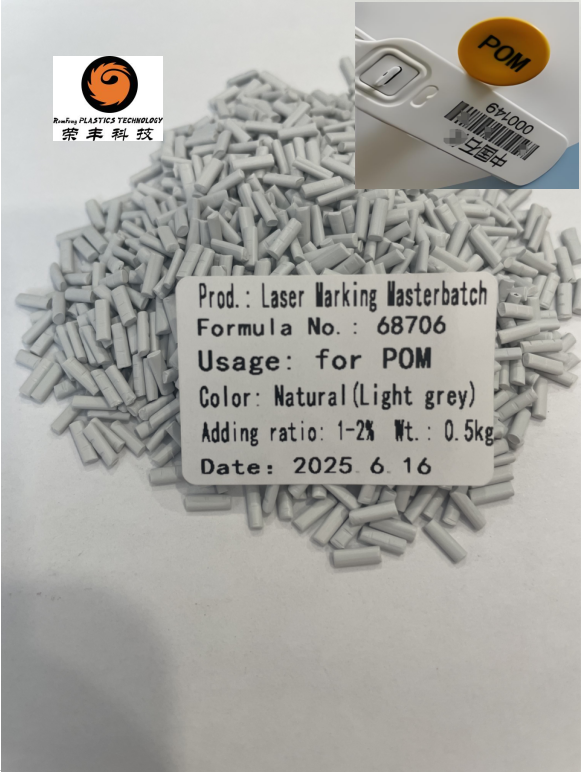

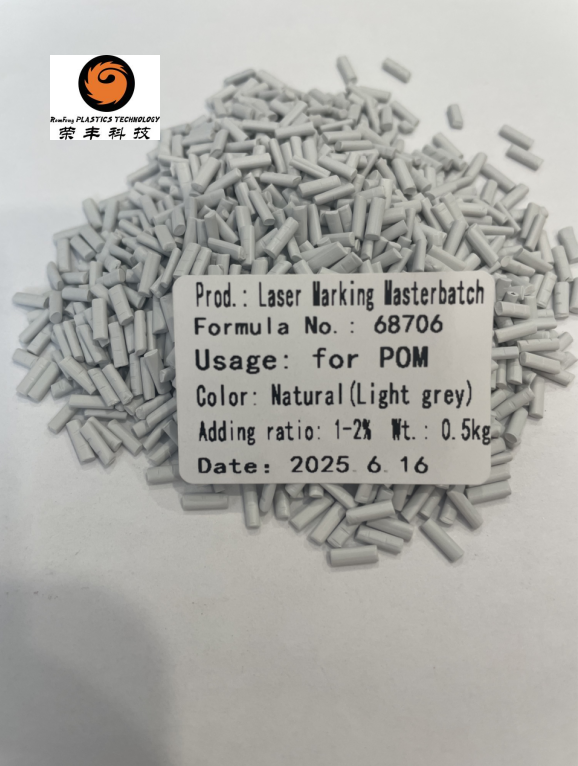

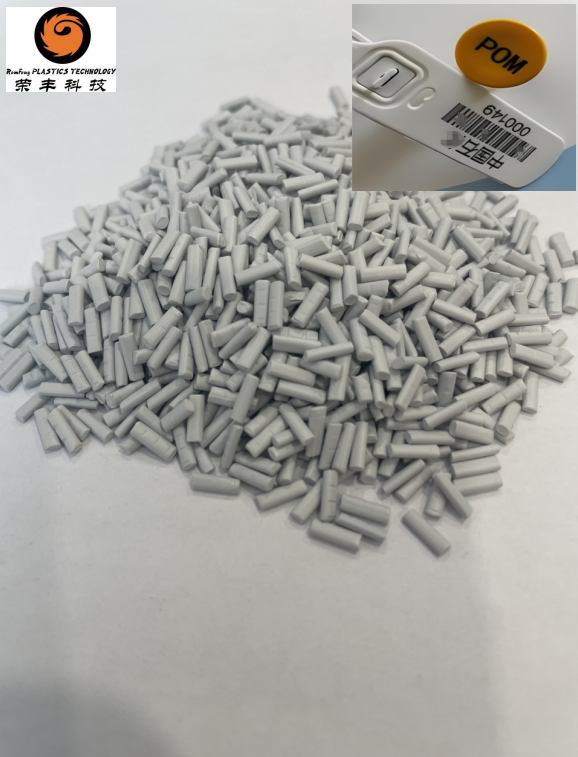

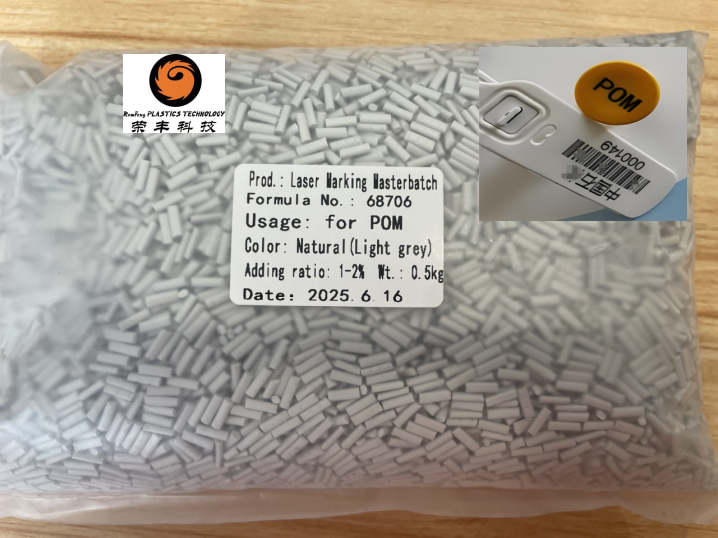

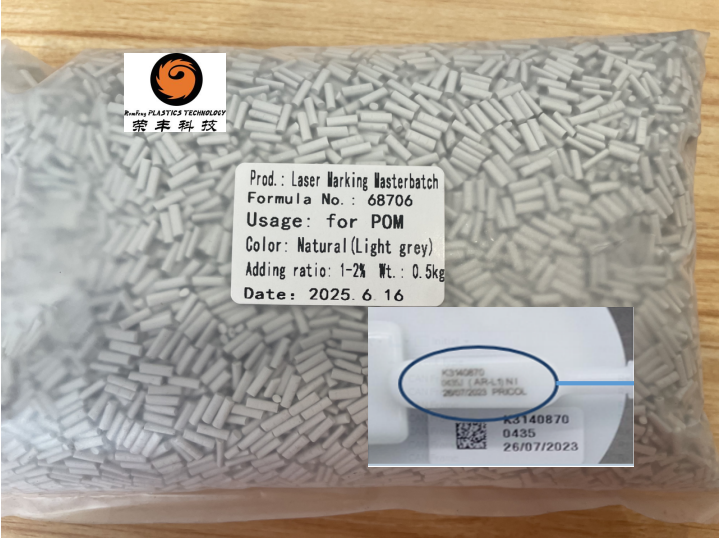

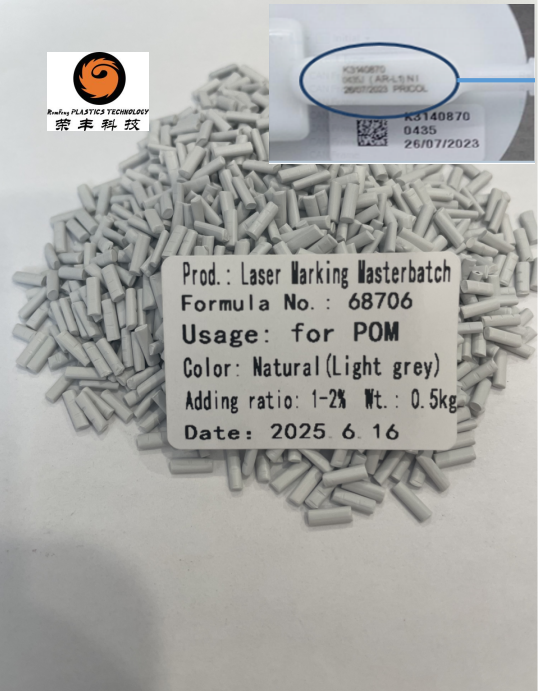

Laser Marking Masterbatch for POM Laser marking masterbatches are specialized additives incorporated into Polyoxymethylene (POM) to enable high-contrast, permanent markings when exposed to laser energy. These formulations contain sensitizers (e.g., metal oxides or pigments) that absorb specific laser wavelengths (commonly fiber or UV lasers), triggering localized reactions like foaming, carbonization, or color changes on the polymer surface. The process is non-contact, high-speed, and eco-friendly, eliminating the need for inks or labels. Key advantages include: Durability: Resistant to abrasion, heat, and chemicals. Precision: Suitable for intricate designs, barcodes, or serial numbers. Compatibility: Engineered to maintain POM’s mechanical properties. Ideal for automotive, electronics, and medical industries requiring part traceability and regulatory compliance.

Categorize:

Additive Masterbatch

Keyword:

**Laser Marking Masterbatch for POM**

In recent years, the demand for advanced materials in various industries has grown exponentially. One such material that has garnered attention is Polyoxymethylene (POM), a high-performance engineering thermoplastic known for its excellent mechanical properties and durability. With the increasing need for efficient and effective marking solutions, laser marking masterbatch for POM has emerged as a vital component in enhancing product identification and branding. This article explores the significance, benefits, and applications of laser marking masterbatch in POM.

**Understanding POM and Its Properties**

Polyoxymethylene, commonly referred to as acetal, is widely used in the manufacturing of precision parts and components due to its outstanding mechanical strength, low friction, and high dimensional stability. These properties make POM an ideal choice for applications in automotive, consumer goods, electronics, and industrial machinery. However, one challenge that manufacturers face with POM is the need for reliable marking methods that do not compromise the material's integrity or appearance.

**The Role of Laser Marking Masterbatch**

Laser marking masterbatch is a concentrated mixture of pigments and additives that can be incorporated into the POM during the compounding process. When exposed to a laser, the masterbatch undergoes a chemical reaction that produces a permanent mark on the surface of the material. This method of marking is gaining popularity due to its precision, speed, and ability to create high-contrast markings without the need for additional inks or solvents.

**Advantages of Laser Marking Masterbatch for POM**

1. **Permanent Marking**: One of the most significant advantages of using laser marking masterbatch is the durability of the marks produced. Unlike traditional printing methods that may fade or wear off over time, laser markings are permanent and resistant to abrasion, chemicals, and environmental factors.

2. **High Precision**: Laser marking allows for intricate designs and fine details to be created with exceptional accuracy. This precision is particularly beneficial for industries that require detailed logos, barcodes, or product information on their components.

3. **Environmentally Friendly**: The use of laser marking masterbatch eliminates the need for harmful solvents and chemicals often associated with traditional marking methods. This makes it a more environmentally friendly option, aligning with the growing emphasis on sustainability in manufacturing processes.

4. **Cost-Effectiveness**: While the initial investment in laser marking equipment may be higher, the long-term savings associated with reduced material waste, lower labor costs, and decreased downtime make it a cost-effective solution for manufacturers.

5. **Versatility**: Laser marking masterbatch can be formulated to suit various POM grades and colors, allowing manufacturers to achieve the desired aesthetic and functional properties. This versatility enables its application across a wide range of industries.

**Applications of Laser Marking Masterbatch in POM**

The applications of laser marking masterbatch for POM are vast and varied. In the automotive industry, for instance, components such as dashboards, switches, and trims can be marked with essential information like part numbers, logos, and safety instructions. This not only aids in identification but also enhances the overall aesthetic appeal of the vehicle.

In the consumer goods sector, laser marking masterbatch can be used for branding and product identification on items such as kitchen appliances, tools, and electronic devices. The ability to create high-contrast markings ensures that brand logos and product information are easily visible, enhancing consumer recognition.

Moreover, in the medical field, POM components used in devices and equipment can be marked with essential information, such as serial numbers and usage instructions, ensuring traceability and compliance with industry regulations. The permanence of laser markings also ensures that critical information remains intact throughout the product's lifecycle.

**Challenges and Considerations**

While the benefits of laser marking masterbatch for POM are numerous, manufacturers must also consider certain challenges. The initial setup costs for laser marking equipment can be significant, and proper training is required to ensure that operators can effectively utilize the technology. Additionally, the compatibility of the masterbatch with different POM grades must be thoroughly evaluated to achieve optimal results.

Another consideration is the potential for thermal effects during the laser marking process. While POM is generally resistant to heat, excessive exposure to laser energy can lead to degradation or discoloration. Therefore, careful calibration of the laser settings is crucial to avoid compromising the material's integrity.

**Conclusion**

Laser marking masterbatch for POM represents a significant advancement in marking technology, offering manufacturers a reliable, efficient, and environmentally friendly solution for product identification and branding. With its numerous advantages, including permanence, precision, and versatility, it is poised to play a critical role in various industries. As manufacturers continue to seek innovative ways to enhance their products, the adoption of laser marking masterbatch is likely to increase, paving the way for more sustainable and effective marking solutions in the future.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.