PRODUCTS

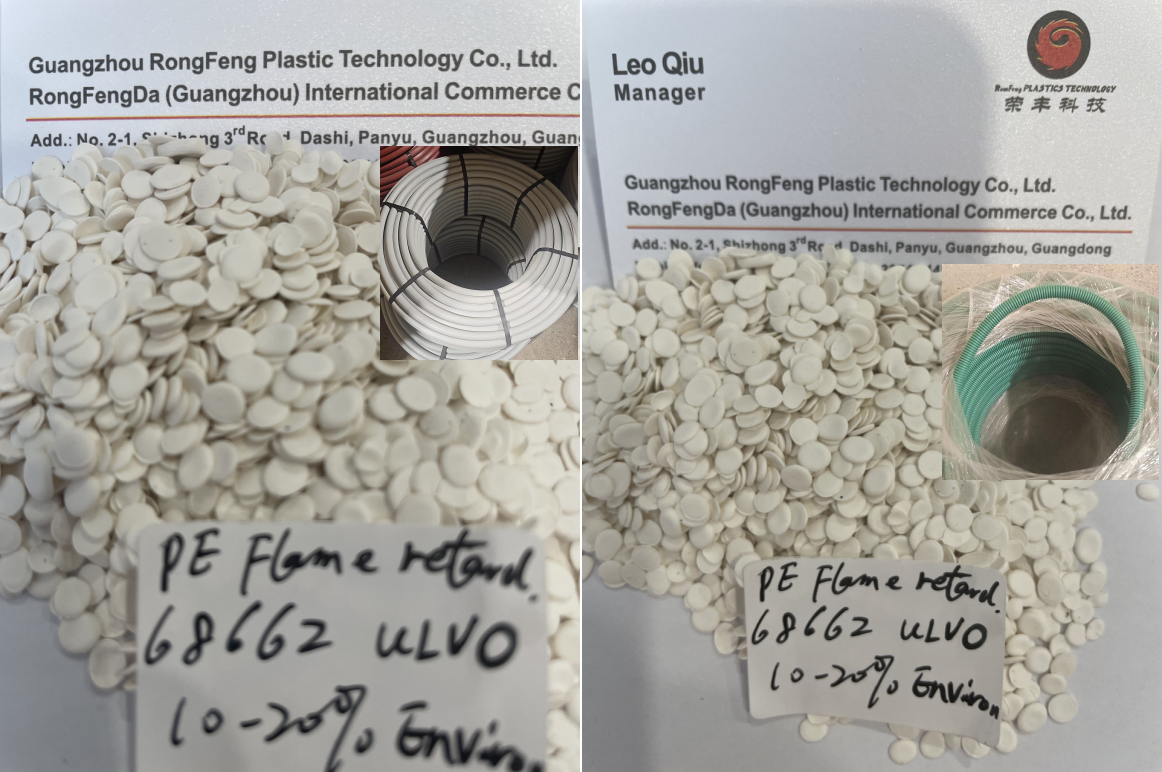

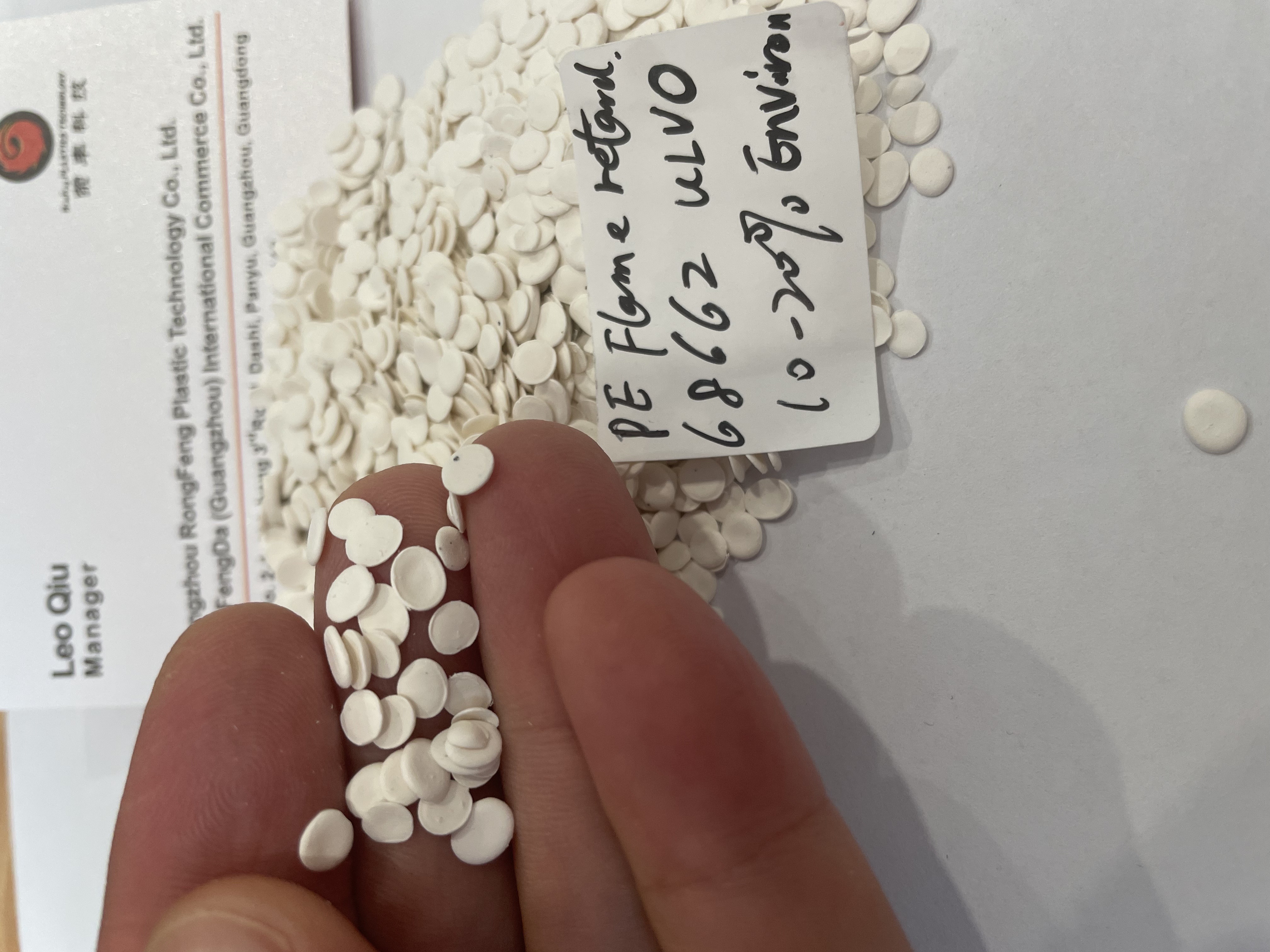

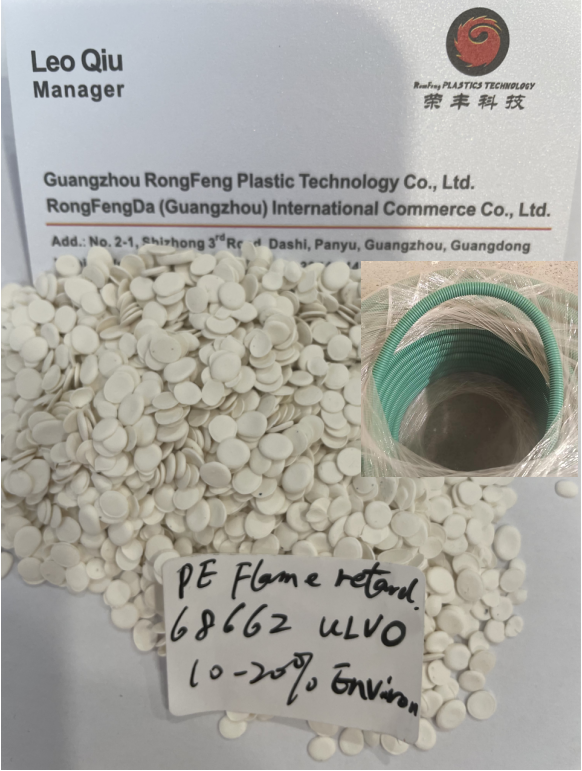

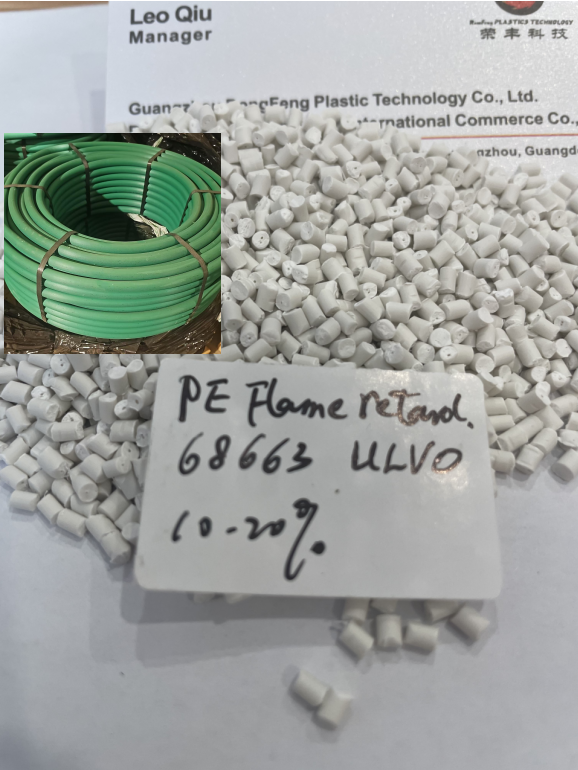

PE Flame Retardant Masterbatch for Wires and Cables

PE Flame Retardant Masterbatch for Wires PE flame retardant masterbatch is a concentrated additive blend designed to enhance the fire resistance of polyethylene (PE) used in wire and cable insulation. It incorporates flame-retardant agents—such as halogenated compounds, phosphorus-based systems, or mineral fillers like aluminum/magnesium hydroxides—which inhibit combustion by interrupting the fire cycle. When added during extrusion, the masterbatch disperses uniformly, ensuring consistent flame retardancy without compromising electrical or mechanical properties. It enables compliance with stringent safety standards (e.g., UL 94, IEC 60332) and reduces smoke/toxic gas emissions. Ideal for construction, automotive, and industrial cables, it offers efficient processing, cost savings, and reliable protection against fire hazards.

Categorize:

Additive Masterbatch

Keyword:

**PE Flame Retardant Masterbatch for Wires and Cables**

In today's rapidly evolving technological landscape, the demand for safe and efficient materials in the electrical and electronics industry has never been higher. One of the most critical aspects of this demand is the need for flame retardant materials, particularly in the manufacturing of wires and cables. This article will delve into the significance of PE (Polyethylene) flame retardant masterbatch, its properties, applications, and advantages, thereby highlighting its role in enhancing safety standards.

**Understanding PE Flame Retardant Masterbatch**

PE flame retardant masterbatch is a concentrated mixture of flame retardant additives dispersed in a polyethylene carrier resin. Masterbatch technology allows manufacturers to easily incorporate flame retardant properties into their products without compromising the base material's integrity. The primary purpose of these masterbatches is to reduce the flammability of wires and cables, ensuring they meet stringent safety regulations and standards.

The composition of a PE flame retardant masterbatch typically includes various flame retardant agents, such as halogenated compounds, phosphorus-based additives, or inorganic fillers. These components work synergistically to inhibit combustion, reduce smoke emissions, and minimize the spread of flames in the event of a fire.

**Importance of Flame Retardancy in Wires and Cables**

Wires and cables are integral components of nearly all electrical systems, from residential wiring to complex industrial machinery. When these materials catch fire, they can contribute to the rapid spread of flames and generate toxic smoke, posing serious risks to life and property. As a result, flame retardancy is crucial in ensuring the safety and reliability of electrical installations.

Regulatory bodies around the world have established stringent fire safety standards for electrical materials. Compliance with these standards is essential for manufacturers, as failure to do so can lead to severe legal and financial repercussions. By utilizing PE flame retardant masterbatch, manufacturers can ensure their wires and cables meet these requirements, providing peace of mind to consumers and businesses alike.

**Properties of PE Flame Retardant Masterbatch**

The effectiveness of a PE flame retardant masterbatch is determined by several key properties. Firstly, its thermal stability is vital, as it must withstand the processing temperatures of polyethylene without degrading. Additionally, the masterbatch should exhibit good dispersion within the polyethylene matrix to ensure uniform flame retardant properties throughout the final product.

Another important property is the masterbatch's compatibility with other additives and fillers. This compatibility allows for the incorporation of additional functionalities, such as UV stabilization or anti-static properties, without compromising the flame retardant performance.

Moreover, the smoke density and toxicity of the materials used in the masterbatch are critical factors. Low smoke and non-toxic characteristics are preferred to enhance safety during a fire event. Manufacturers are increasingly focusing on developing eco-friendly flame retardant solutions that do not release harmful substances when exposed to high temperatures.

**Applications in Wires and Cables**

PE flame retardant masterbatch finds extensive applications in various types of wires and cables, including power cables, communication cables, and specialty wires used in automotive and aerospace industries. These applications require materials that not only provide electrical insulation but also offer fire resistance.

For instance, in residential and commercial buildings, flame retardant cables are essential for preventing the spread of fire through electrical systems. In industrial settings, such as factories and power plants, the use of flame retardant wires is critical to ensure the safety of personnel and equipment.

Furthermore, the automotive industry is increasingly adopting PE flame retardant masterbatch for wiring harnesses, where fire safety is paramount due to the potential for electrical faults. The aerospace sector also benefits from these materials, as they help meet the stringent safety regulations governing aircraft wiring.

**Advantages of Using PE Flame Retardant Masterbatch**

The use of PE flame retardant masterbatch offers numerous advantages for manufacturers and end-users alike. One of the primary benefits is the ease of processing. The masterbatch can be easily integrated into the production process, allowing for efficient manufacturing without significant changes to existing equipment.

Additionally, the incorporation of flame retardant properties does not compromise the mechanical properties of the polyethylene. This means that wires and cables can maintain their flexibility, strength, and durability while achieving the necessary fire safety standards.

Cost-effectiveness is another significant advantage. By using masterbatch technology, manufacturers can achieve the desired flame retardant properties without the need for expensive additives or extensive formulation changes. This can lead to lower production costs and improved profit margins.

Moreover, the environmental impact of flame retardant materials is a growing concern. PE flame retardant masterbatches can be designed to be more environmentally friendly, utilizing non-toxic and sustainable materials that align with global sustainability goals.

**Conclusion**

In conclusion, PE flame retardant masterbatch plays a vital role in the production of safe and reliable wires and cables. Its ability to enhance flame resistance without compromising the material's integrity makes it an essential component in meeting modern safety standards. As industries continue to prioritize fire safety and environmental responsibility, the development and use of PE flame retardant masterbatches will undoubtedly grow. Manufacturers who embrace these innovative solutions will not only enhance the safety of their products but also contribute to a more sustainable future in the electrical and electronics industry.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.