PRODUCTS

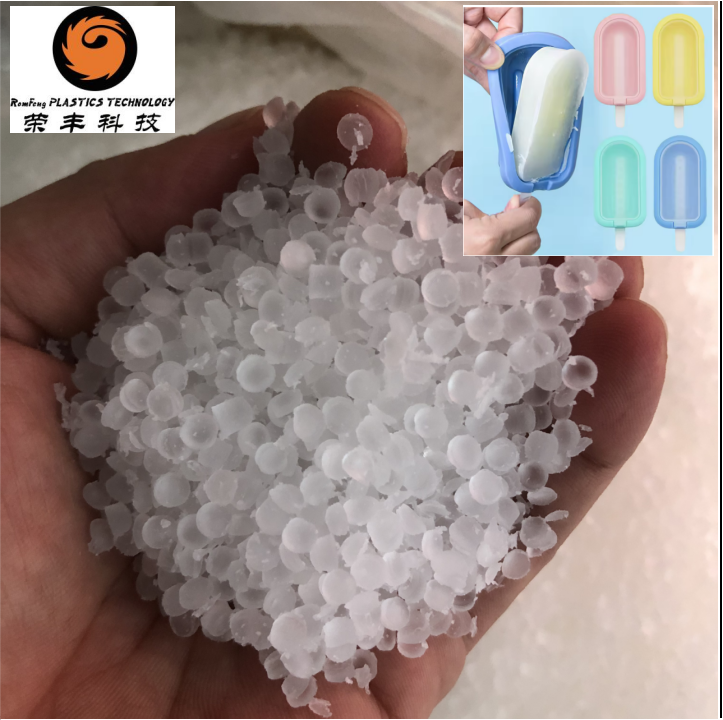

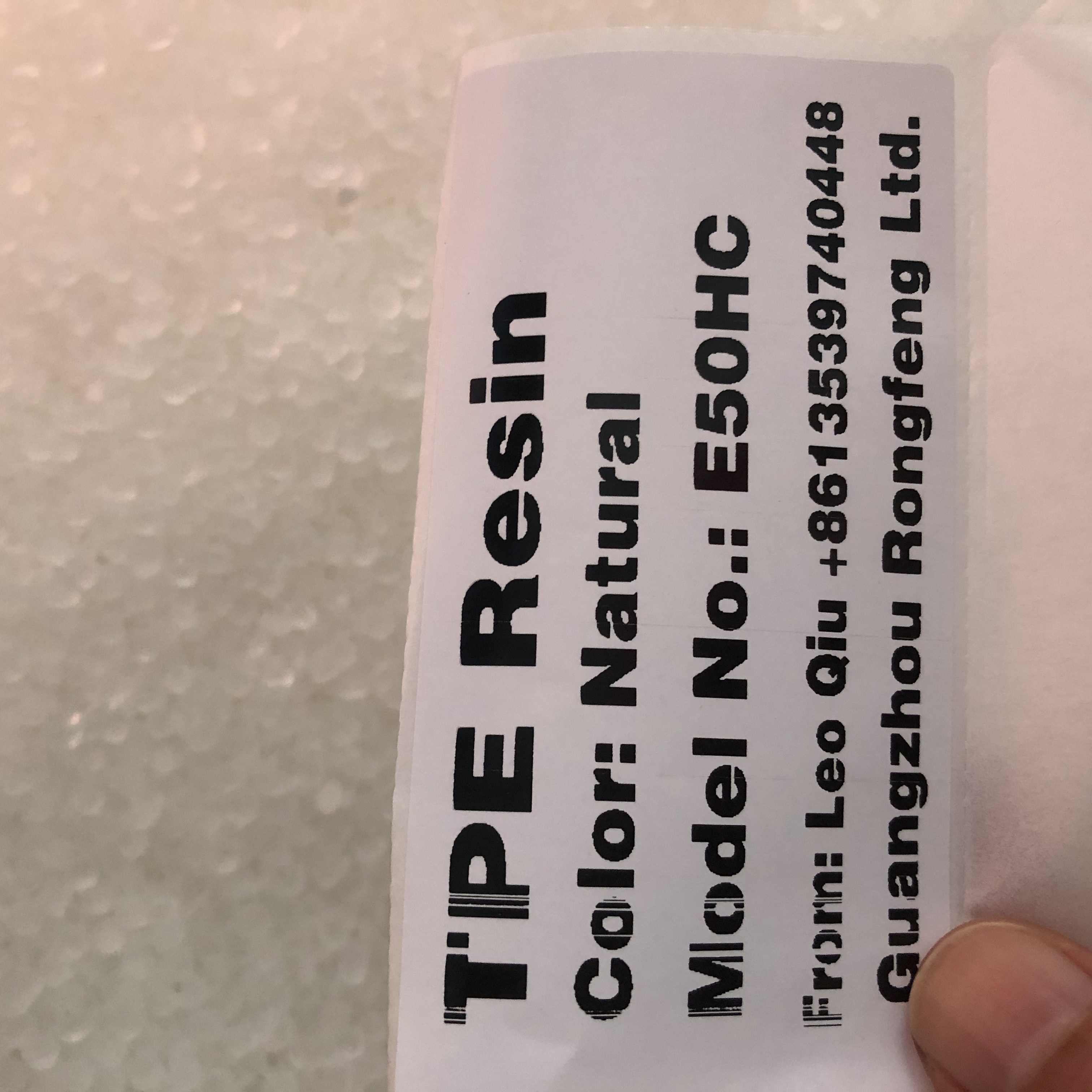

TPE Materials for Ice Cream Molds

TPE Material for Ice Cream Molds Thermoplastic Elastomers (TPE) are ideal for ice cream molds due to their flexibility, durability, and food-grade safety. Key properties include: Softness & Non-Stick: Easy demolding without damaging delicate ice cream shapes. Food Compliance: FDA/EU-approved formulations resist oils and low temperatures (-30°C). Reusability: Withstand repeated freezing/thawing cycles without cracking. Eco-Friendly: Recyclable alternatives to silicone or PVC. Common types include SEBS-based TPEs for elasticity and PP-blended TPEs for rigidity. Applications extend to DIY home molds and industrial production lines.

Categorize:

Modified Materials For Wires And Cables

TPU TPE Masterbatch

Keyword:

**TPE Materials for Ice Cream Molds**

The world of ice cream is vast and delicious, offering a variety of flavors, textures, and presentations. However, behind the scenes of this delightful treat lies a critical component that often goes unnoticed: the mold. The choice of material for ice cream molds can significantly affect the quality of the final product. Among the various materials available, Thermoplastic Elastomers (TPE) have emerged as a popular choice for manufacturing ice cream molds. This article explores the characteristics, advantages, and applications of TPE materials in the realm of ice cream molds.

**Understanding TPE Materials**

Thermoplastic Elastomers, or TPEs, are a class of polymers that combine the properties of rubber with the processability of thermoplastics. This unique combination allows TPEs to be molded and shaped like plastics while maintaining the elasticity and flexibility characteristic of rubber. TPEs can be easily processed using conventional methods such as injection molding, extrusion, and blow molding, making them an ideal choice for creating intricate designs and shapes for ice cream molds.

TPEs are composed of two main components: a hard segment and a soft segment. The hard segment provides strength and stability, while the soft segment offers flexibility and elasticity. This duality allows TPEs to withstand repeated use and maintain their shape over time, making them suitable for the demands of ice cream production.

**Advantages of TPE for Ice Cream Molds**

1. **Flexibility and Elasticity**: One of the most significant advantages of TPEs is their flexibility and elasticity. Ice cream molds often require bending and twisting during the demolding process. TPEs provide the necessary flexibility to release the ice cream without damaging the product, ensuring a perfect shape every time.

2. **Temperature Resistance**: Ice cream production involves exposure to various temperatures, from freezing to room temperature. TPE materials are designed to withstand these temperature fluctuations without losing their properties. They remain stable and functional, ensuring that the molds perform well throughout the entire production process.

3. **Durability**: TPEs are known for their excellent durability. They can endure repeated use and cleaning cycles without degrading or losing their effectiveness. This longevity makes TPE molds a cost-effective solution for ice cream manufacturers, as they do not need to be replaced frequently.

4. **Non-Toxic and Food Safe**: Safety is a paramount concern in the food industry. TPE materials are generally non-toxic and can be formulated to meet food safety regulations. This characteristic makes TPEs an ideal choice for ice cream molds, ensuring that the final product is safe for consumption.

5. **Customizability**: TPEs can be easily modified to achieve specific properties, such as hardness, color, and transparency. This versatility allows manufacturers to create unique and attractive ice cream molds that can enhance the presentation of the final product.

**Applications of TPE in Ice Cream Production**

The applications of TPE materials in ice cream production are diverse. They are commonly used to create molds for various ice cream shapes, including traditional cones, popsicles, and novelty ice cream bars. The flexibility of TPE allows for intricate designs that can capture the essence of the ice cream's flavor or theme.

In addition to traditional molds, TPEs are also used in creating customizable molds for special events or promotions. For example, brands can design molds that reflect seasonal themes, holidays, or brand logos, adding an element of fun and creativity to the ice cream experience.

Furthermore, TPE molds can be used in combination with other materials to enhance their functionality. For instance, they can be lined with silicone or coated with non-stick surfaces to improve the release of the ice cream and ease the cleaning process.

**Challenges and Considerations**

While TPE materials offer numerous advantages, there are also challenges to consider. One of the primary challenges is the cost. TPEs can be more expensive than traditional materials like polypropylene or polyethylene. However, the durability and longevity of TPE molds can offset the initial investment over time.

Another consideration is the formulation of TPEs. Not all TPEs are created equal, and selecting the right formulation for specific applications is crucial. Manufacturers must ensure that the chosen TPE meets food safety standards and performs well under the intended conditions.

**Conclusion**

In conclusion, TPE materials represent a significant advancement in the production of ice cream molds. Their unique properties, including flexibility, temperature resistance, and durability, make them an ideal choice for manufacturers looking to create high-quality, innovative ice cream products. As the ice cream industry continues to evolve, the use of TPEs is likely to expand, offering new opportunities for creativity and efficiency in mold design. With their ability to enhance both the functionality and aesthetics of ice cream molds, TPE materials are poised to play a vital role in shaping the future of ice cream production.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.