PRODUCTS

PUR Materials for Cables

Polyurethane (PUR) is widely used in cable jacketing due to its superior properties: Exceptional Toughness & Abrasion Resistance: Withstands harsh physical environments better than many plastics. Flexibility & Elasticity: Maintains flexibility over a wide temperature range, even at low temperatures, making it ideal for constant-flex applications (e.g., robotics, automation, trailing cables). Chemical & Oil Resistance: Resists oils, greases, solvents, and many chemicals, crucial for industrial settings. Cut & Tear Resistance: Offers high resistance to mechanical damage. Environmental Resistance: Good resistance to ozone, weathering, and hydrolysis (especially specific formulations), suitable for outdoor use. Plasticizer-Free: Unlike PVC, PUR doesn't rely on migrating plasticizers, ensuring long-term flexibility retention. PUR jackets are common in robotic arms, drag chains, industrial machinery, portable power cables, and demanding outdoor applications. It's available as castable liquid systems or thermoplastic pellets (TPU).

Categorize:

Modified Materials For Wires And Cables

Keyword:

**PUR Materials for Cables**

Polyurethane (PUR) materials have gained significant traction in the cable industry due to their unique properties and versatility. As technology continues to advance, the demand for durable and high-performance cables is on the rise. This article explores the various aspects of PUR materials used in cables, including their composition, benefits, applications, and future trends.

**Composition of PUR Materials**

Polyurethane is a polymer composed of organic units joined by carbamate (urethanes) links. It can be synthesized through the reaction of diisocyanates with polyols. The flexibility in the selection of raw materials allows for the creation of PUR with varying properties, making it suitable for a wide range of applications. The two primary types of polyurethane are thermoplastic polyurethane (TPU) and thermosetting polyurethane, each offering distinct advantages depending on the intended use.

Thermoplastic polyurethane is particularly popular in cable manufacturing because it can be easily processed and reshaped when heated. This feature allows for efficient production techniques, such as extrusion and injection molding, making it an ideal choice for mass production. On the other hand, thermosetting polyurethane provides excellent chemical resistance and thermal stability, making it suitable for more demanding applications.

**Benefits of PUR Materials in Cables**

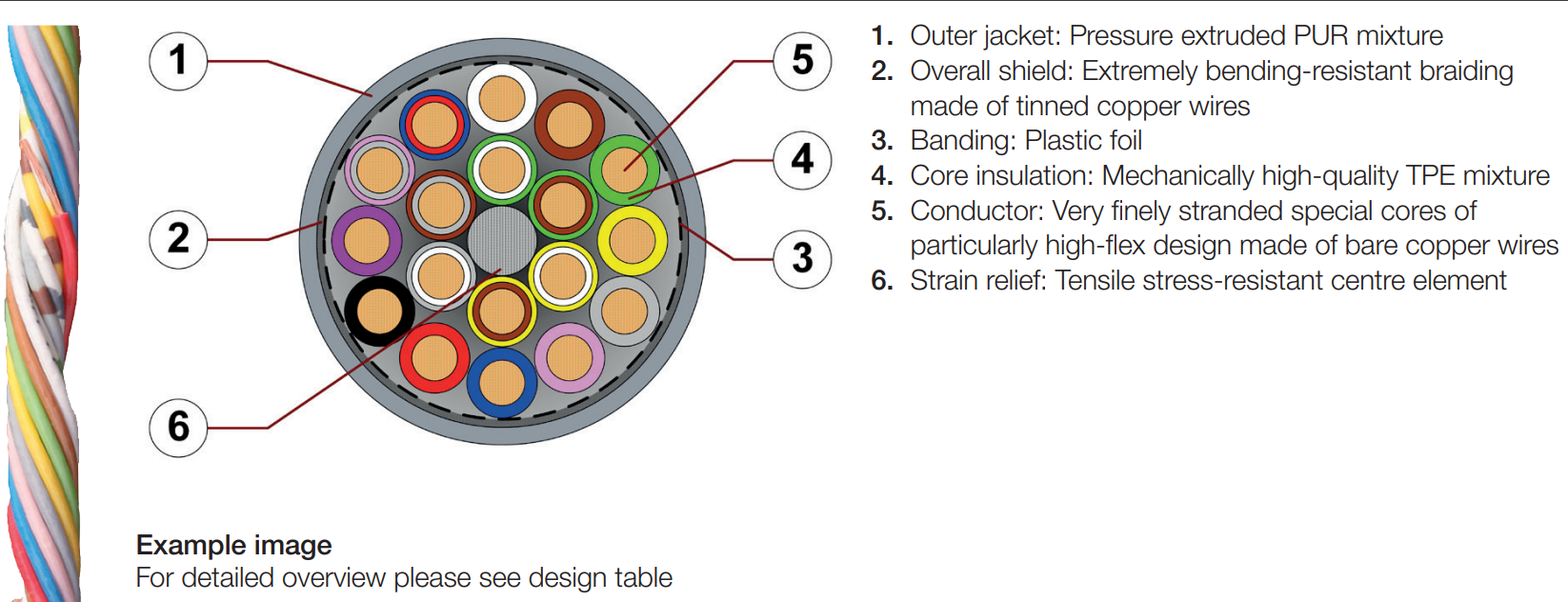

One of the most significant advantages of using PUR materials in cables is their exceptional mechanical properties. Cables made from PUR exhibit high tensile strength, tear resistance, and abrasion resistance, making them ideal for harsh environments. This durability ensures a longer lifespan for cables, reducing the need for frequent replacements and maintenance.

In addition to mechanical strength, PUR materials also offer excellent flexibility and elasticity. This characteristic allows cables to bend and twist without compromising their integrity, making them suitable for applications where movement is frequent, such as in robotics or automotive systems. The flexibility of PUR cables also contributes to easier installation and routing, particularly in tight spaces.

Moreover, PUR materials are known for their resistance to chemicals, oils, and fuels. This makes them suitable for use in industrial settings where cables may be exposed to harsh substances. The ability of PUR to withstand environmental factors, such as UV radiation and moisture, further enhances its appeal for outdoor applications.

**Applications of PUR Cables**

PUR cables find applications in various industries due to their unique properties. In the automotive industry, they are used for wiring harnesses, sensors, and other electronic components that require flexibility and durability. The increasing complexity of automotive systems necessitates cables that can withstand vibration, heat, and exposure to chemicals, making PUR an ideal choice.

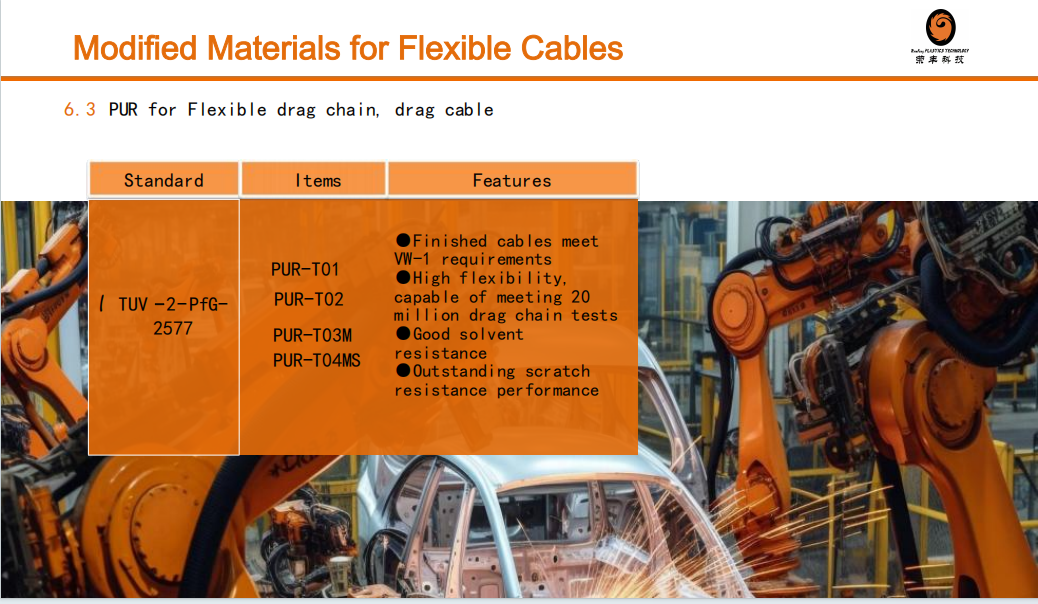

In the robotics and automation sector, PUR cables are essential for ensuring reliable performance. These cables must be able to handle continuous movement and bending without failing. PUR’s flexibility and strength make it suitable for robotic arms, conveyor systems, and other automated machinery.

The telecommunications industry also benefits from PUR cables. As the demand for high-speed data transmission grows, cables must meet specific performance criteria, including resistance to interference and environmental factors. PUR materials provide the necessary properties to ensure signal integrity and reliability.

Additionally, PUR cables are commonly used in the medical field. They are utilized in various medical devices and equipment, where flexibility and resistance to sterilization processes are critical. PUR’s biocompatibility and ease of cleaning make it suitable for applications such as surgical instruments and patient monitoring devices.

**Future Trends in PUR Cable Technology**

As technology continues to evolve, the demand for more advanced cable solutions will increase. The development of smart cables that integrate sensors and communication capabilities is one area of growth. PUR materials can support these innovations by providing the necessary mechanical properties while allowing for the incorporation of electronic components.

Furthermore, sustainability is becoming a crucial consideration in cable manufacturing. The industry is moving towards the use of bio-based polyurethanes and recyclable materials to reduce environmental impact. Research and development efforts are focused on creating PUR materials that not only meet performance standards but also align with sustainability goals.

The advent of Industry 4.0 and the Internet of Things (IoT) is also influencing the design and use of cables. As devices become more interconnected, cables must be capable of handling increased data loads and providing reliable connectivity. PUR materials will play a vital role in the development of these next-generation cables.

**Conclusion**

PUR materials have established themselves as a cornerstone in the cable industry, offering a combination of strength, flexibility, and resistance to harsh conditions. Their versatility allows for a wide range of applications across various sectors, including automotive, robotics, telecommunications, and medical devices. As the demand for advanced cable solutions grows, PUR materials will continue to evolve, embracing sustainability and technological advancements. The future of PUR cables looks promising, with ongoing innovations poised to meet the challenges of a rapidly changing technological landscape.

Certification

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.