PRODUCTS

TPE Materials for Springs

Thermoplastic Elastomers (TPEs) offer unique advantages for spring applications where traditional metal springs are unsuitable. Key benefits include: Lightweight: Significantly lighter than metal springs. Corrosion Resistance: Inherent resistance to moisture and many chemicals. Design Flexibility: Easily molded into complex shapes and integrated during part assembly. Quiet Operation: Dampen vibration and noise effectively. Cost-Effective Processing: Efficient high-volume molding (injection, extrusion) reduces part cost. Common TPE Types & Uses: TPV (PP/EPDM): Excellent compression set resistance for seals & pads. COPE (TPC-ET): High resilience & fatigue resistance for dynamic components. TPU: Offers high abrasion resistance and load-bearing capacity. SBC (TPS): Good low-temperature flexibility for simpler springs/dampers. Limitations: Lower stiffness, temperature resistance (<120-170°C typically), and load capacity compared to metal. Best suited for low-to-medium force applications requiring specific properties like chemical resistance, quietness, or complex geometry.

Categorize:

Modified Materials For Wires And Cables

Keyword:

**TPE Materials for Springs**

Thermoplastic elastomers (TPEs) have gained significant traction in various industries due to their unique properties that combine the best features of rubber and plastic. Among their many applications, TPE materials are increasingly being used for the production of springs. This article will explore the characteristics, advantages, and applications of TPE materials in spring manufacturing.

**Understanding TPE Materials**

TPEs are a class of materials that exhibit both thermoplastic and elastomeric properties. They can be processed like plastics, allowing for easy molding and shaping, while also providing the flexibility and elasticity characteristic of rubber. This dual nature makes TPEs suitable for a wide range of applications, including automotive parts, medical devices, and consumer goods.

The primary types of TPEs include styrenic block copolymers (SBCs), thermoplastic polyurethanes (TPUs), thermoplastic polyolefins (TPOs), and thermoplastic copolyesters (TPCs). Each type has its own set of properties, which can be tailored to meet specific requirements, making TPEs an attractive option for spring applications.

**Advantages of TPEs for Springs**

1. **Flexibility and Elasticity**: TPEs provide excellent flexibility and elasticity, allowing springs made from these materials to return to their original shape after deformation. This characteristic is crucial for maintaining the functionality of springs in various applications.

2. **Chemical Resistance**: TPEs are often resistant to a wide range of chemicals, including oils, greases, and solvents. This resistance is essential for springs used in environments where exposure to harsh chemicals is a concern.

3. **Durability**: Springs made from TPE materials exhibit good wear resistance and can withstand repeated stress and strain without significant degradation. This durability ensures a longer lifespan and reduces the need for frequent replacements.

4. **Lightweight**: Compared to traditional metal springs, TPE springs are significantly lighter, making them ideal for applications where weight reduction is critical, such as in automotive and aerospace industries.

5. **Ease of Processing**: TPEs can be easily processed using conventional plastic processing techniques such as injection molding, extrusion, and blow molding. This ease of processing allows for the efficient production of complex spring designs.

6. **Customizable Properties**: The properties of TPEs can be tailored by adjusting the formulation, enabling manufacturers to create springs with specific hardness, flexibility, and tensile strength to meet the demands of different applications.

**Applications of TPE Springs**

TPE springs find applications in a variety of industries due to their advantageous properties.

1. **Automotive Industry**: In the automotive sector, TPE springs are used in suspension systems, seat mechanisms, and vibration dampening applications. Their lightweight nature helps improve fuel efficiency, while their durability ensures reliable performance under varying conditions.

2. **Consumer Electronics**: TPE springs are increasingly used in consumer electronics, such as keyboards, remote controls, and mobile devices. Their ability to provide tactile feedback enhances user experience, while their resistance to wear ensures longevity.

3. **Medical Devices**: In the medical field, TPE springs are utilized in devices that require precise movement and flexibility, such as surgical instruments and drug delivery systems. The biocompatibility of certain TPEs also makes them suitable for medical applications.

4. **Industrial Applications**: TPE springs are employed in various industrial machinery and equipment where flexibility and durability are essential. They can be found in conveyor systems, packaging machinery, and automation equipment.

5. **Sports and Recreation**: TPE springs are used in sports equipment, such as fitness machines and recreational gear, providing the necessary support and flexibility for optimal performance.

**Challenges and Considerations**

While TPE materials offer numerous advantages for spring manufacturing, there are also challenges and considerations to keep in mind.

1. **Temperature Sensitivity**: TPEs can be sensitive to temperature changes, which may affect their performance in extreme environments. It is crucial to select the appropriate TPE grade for applications exposed to high or low temperatures.

2. **Cost Factors**: While TPEs can provide long-term savings due to their durability and reduced maintenance needs, the initial cost of TPE materials may be higher than traditional metals. Manufacturers must weigh the benefits against the costs when making material choices.

3. **Limited Load Capacity**: TPE springs may not be suitable for high-load applications where metal springs excel. Understanding the load requirements of the application is essential to ensure the right material is chosen.

**Conclusion**

TPE materials are revolutionizing the spring manufacturing industry by offering a versatile and effective alternative to traditional metal springs. Their unique properties, including flexibility, chemical resistance, and ease of processing, make them suitable for a wide range of applications across various industries. While challenges exist, the benefits of TPE springs often outweigh the drawbacks, leading to increased adoption in sectors such as automotive, consumer electronics, and medical devices. As technology advances and material formulations continue to improve, the future of TPE springs looks promising, paving the way for innovative solutions in engineering and design.

Certification

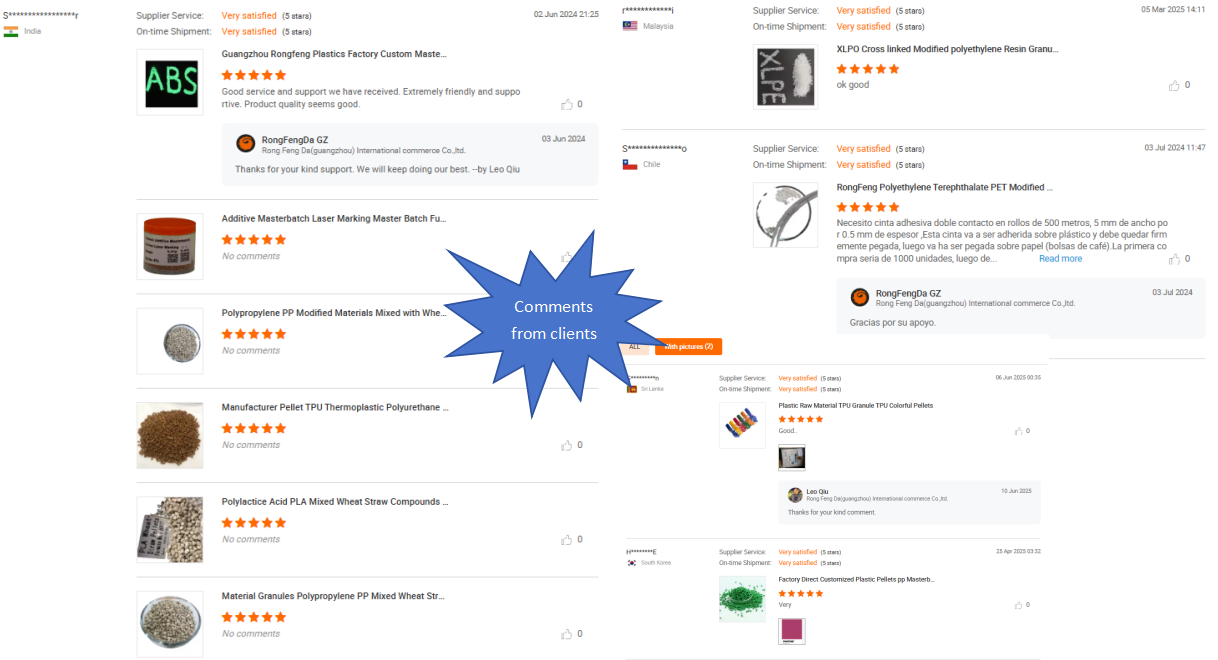

We rely on science and technology to create great achievements, and we see real achievements in the details. Every step of the way, my team and friends and I feel solid.

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit our salon personally. We would be happy to answer your questions.